fendersrule

Well-Known Member

- Joined

- Oct 11, 2018

- Messages

- 703

- Reaction score

- 342

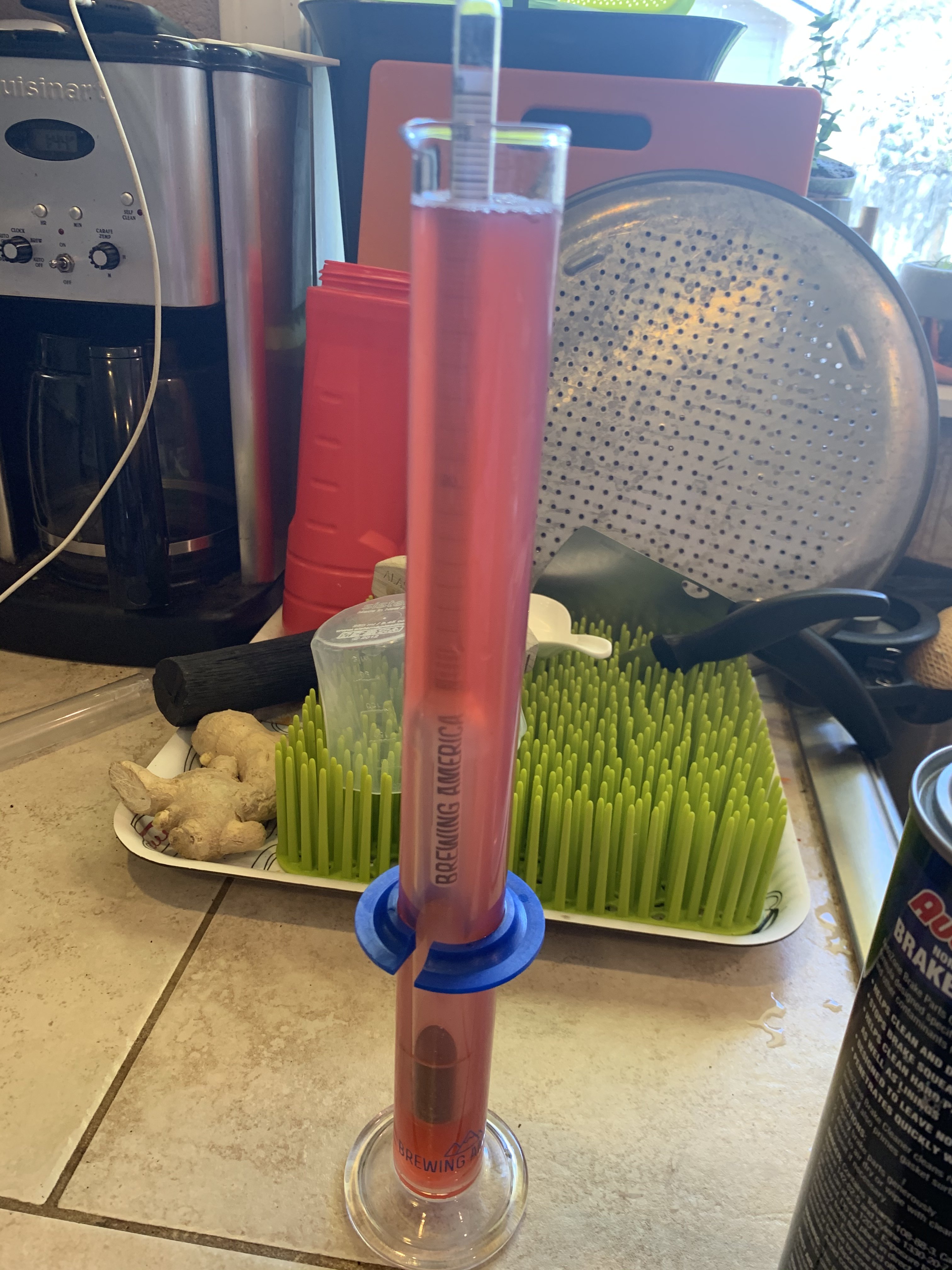

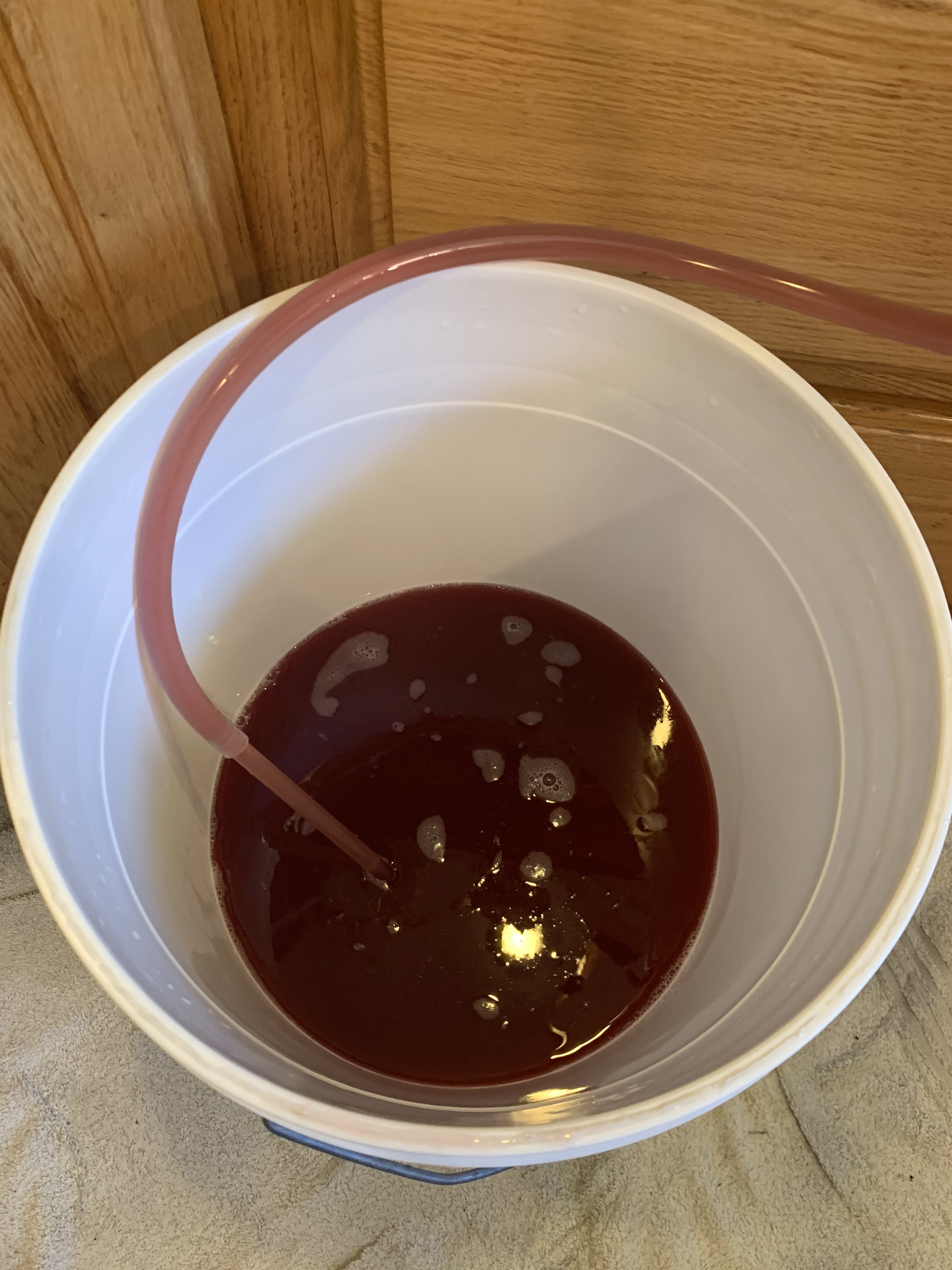

It's been 3-4 days since we pitched the super sour. I can tell by the airlock that she's pretty much done with whatever fermentation was left from it. A few more days won't hurt. It's time to dry hop.

We tasted it yesterday and today and yep, it's SOUR now. We're actually quite pleased with the sour level right now (and we love strong sours) but will plan to dry hop tomorrow. @RPh_Guy, we are so happy this worked for us and have you to thank. PM me your FB addy if you'd like. I'm thinking for these that 3-5 days of dry hopping time will be plenty. Just enough time for the hops to break down and sink to the bottom. It needs to be bottled in a slight hurry.

Here are my spare hops in the freezer. Please help me choose which hop for what vessel. I have two 5G to dry hop. One is peach, and one is blackberry. I assume .5 ounce for each one should do it?

1) Moteuka

2) Sirachi Ace

3) Cascade

4) Magnum

5) Nugget

Let me know what you would do. As much as I've brewed, I am far from a hop expert. I can tell certain hops apart, but I am far from having intimate knowledge with most hops out there.

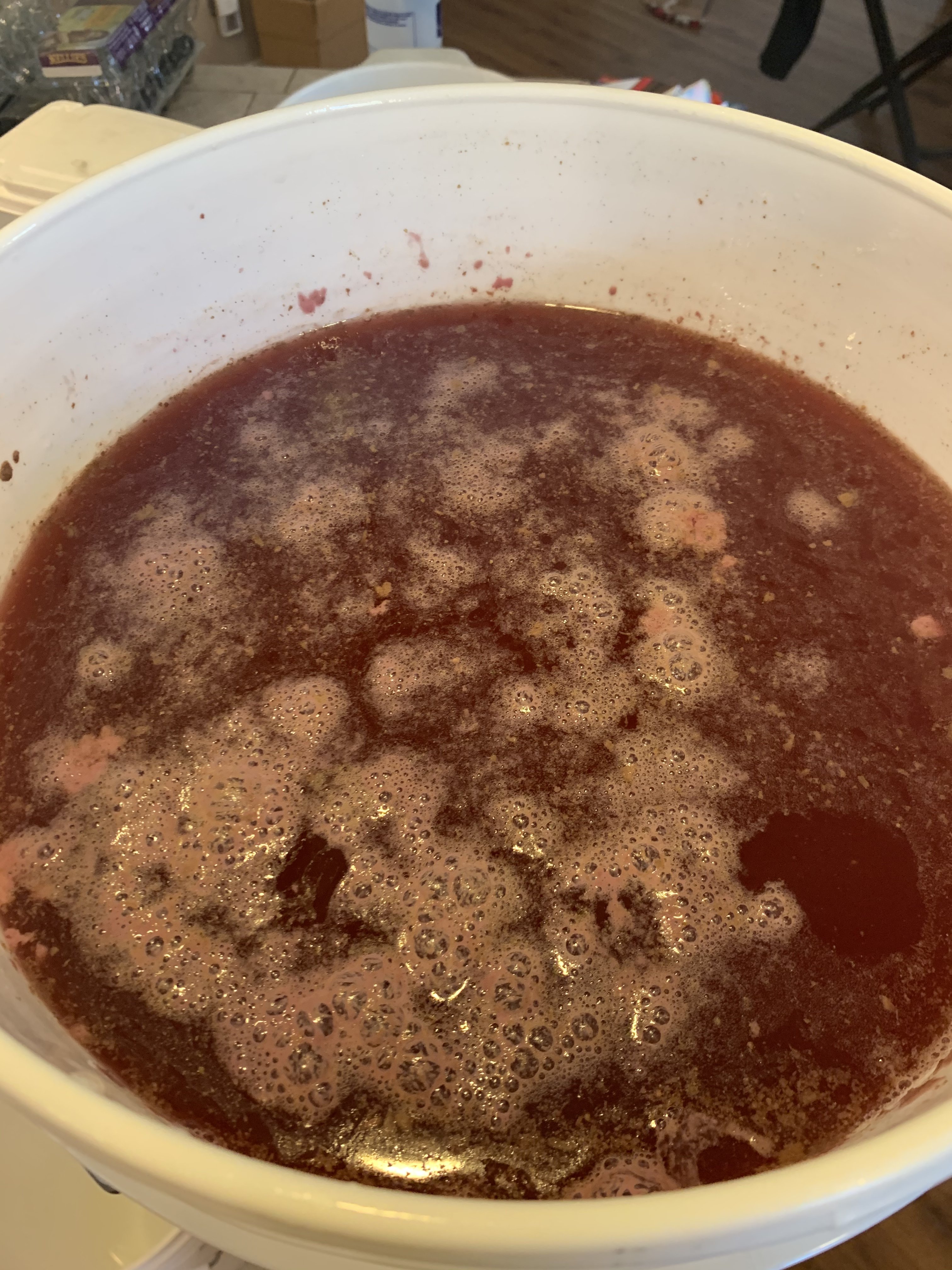

Guys, the super post-sour process works GREAT. Like, really great. RPH, you should post this "backup plan" in your original post. It worked so well that I might actually prefer this method. I'll try the co-sour again with live, non-expired bugs, but damn, this method made a great sour. Definitely update the thread to include Goodbelly as a viable option too since it's available everywhere and is cheap. It just adds a character to it that is really good for fruit beers. We used Pomegranate blackberry. It colored the wort a deep red (2 gallons if Pilsen DME wort) with 30 ounces of Goodbelly (slightly less than the 34-36 ounces it comes in--hey, I had to drink some first). But the "red" completely went away after the 9-day souring process was over. It was yellow at that point, so whatever Goodbelly color you can find would work, if you're worried about coloring your beer based on the volume that I did-don't be. The color fades out, is what I'm saying.

The only "negative" is that it takes at least 5 days, up to 10 days, depending on how much heat you have on the super sour vessel. We had ours most of the days at 76-78F, and decided 9 days was simply enough. For anyone that will try this that can keep this same heat, my recommendation is to work backward from here because I think (I don't know, through intuition) that it will be ready around day 5. One other negative is that the calcium carbonate really leaves a HARD barrier on the bottom of the vessel. Just keep that in mind that you will be scrubbing the @**** out of it (carefully, of course with a non-scratching agent). PBW removed more than half of the "chalk' by soaking alone (impressive), but it will take extra time to clean the vessel from this method. The positives heavily outweigh the negatives however because it just WORKS. It's a solid as hell backup plan.

If you think about it, 5,000 ft view, post-souring is the same as pre-souring. You have a vessel that has no yeast (hopefully) and you are allowing it to sour prior to a yeast pitch. With post-souring, you are not using a "kettle" (like you would be "pre-souring"). This means you can put it in a sealed, Star-Stan'd container, with an airlock, that will pretty much guarantee success.

Co-souring >/= Post Souring > Pre-souring.

Kettle Souring (Pre-Souring) is just stupid IMO. Increased risk for what?

We tasted it yesterday and today and yep, it's SOUR now. We're actually quite pleased with the sour level right now (and we love strong sours) but will plan to dry hop tomorrow. @RPh_Guy, we are so happy this worked for us and have you to thank. PM me your FB addy if you'd like. I'm thinking for these that 3-5 days of dry hopping time will be plenty. Just enough time for the hops to break down and sink to the bottom. It needs to be bottled in a slight hurry.

Here are my spare hops in the freezer. Please help me choose which hop for what vessel. I have two 5G to dry hop. One is peach, and one is blackberry. I assume .5 ounce for each one should do it?

1) Moteuka

2) Sirachi Ace

3) Cascade

4) Magnum

5) Nugget

Let me know what you would do. As much as I've brewed, I am far from a hop expert. I can tell certain hops apart, but I am far from having intimate knowledge with most hops out there.

Guys, the super post-sour process works GREAT. Like, really great. RPH, you should post this "backup plan" in your original post. It worked so well that I might actually prefer this method. I'll try the co-sour again with live, non-expired bugs, but damn, this method made a great sour. Definitely update the thread to include Goodbelly as a viable option too since it's available everywhere and is cheap. It just adds a character to it that is really good for fruit beers. We used Pomegranate blackberry. It colored the wort a deep red (2 gallons if Pilsen DME wort) with 30 ounces of Goodbelly (slightly less than the 34-36 ounces it comes in--hey, I had to drink some first). But the "red" completely went away after the 9-day souring process was over. It was yellow at that point, so whatever Goodbelly color you can find would work, if you're worried about coloring your beer based on the volume that I did-don't be. The color fades out, is what I'm saying.

The only "negative" is that it takes at least 5 days, up to 10 days, depending on how much heat you have on the super sour vessel. We had ours most of the days at 76-78F, and decided 9 days was simply enough. For anyone that will try this that can keep this same heat, my recommendation is to work backward from here because I think (I don't know, through intuition) that it will be ready around day 5. One other negative is that the calcium carbonate really leaves a HARD barrier on the bottom of the vessel. Just keep that in mind that you will be scrubbing the @**** out of it (carefully, of course with a non-scratching agent). PBW removed more than half of the "chalk' by soaking alone (impressive), but it will take extra time to clean the vessel from this method. The positives heavily outweigh the negatives however because it just WORKS. It's a solid as hell backup plan.

If you think about it, 5,000 ft view, post-souring is the same as pre-souring. You have a vessel that has no yeast (hopefully) and you are allowing it to sour prior to a yeast pitch. With post-souring, you are not using a "kettle" (like you would be "pre-souring"). This means you can put it in a sealed, Star-Stan'd container, with an airlock, that will pretty much guarantee success.

Co-souring >/= Post Souring > Pre-souring.

Kettle Souring (Pre-Souring) is just stupid IMO. Increased risk for what?

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)