TrubDude

Well-Known Member

- Joined

- Nov 19, 2017

- Messages

- 49

- Reaction score

- 19

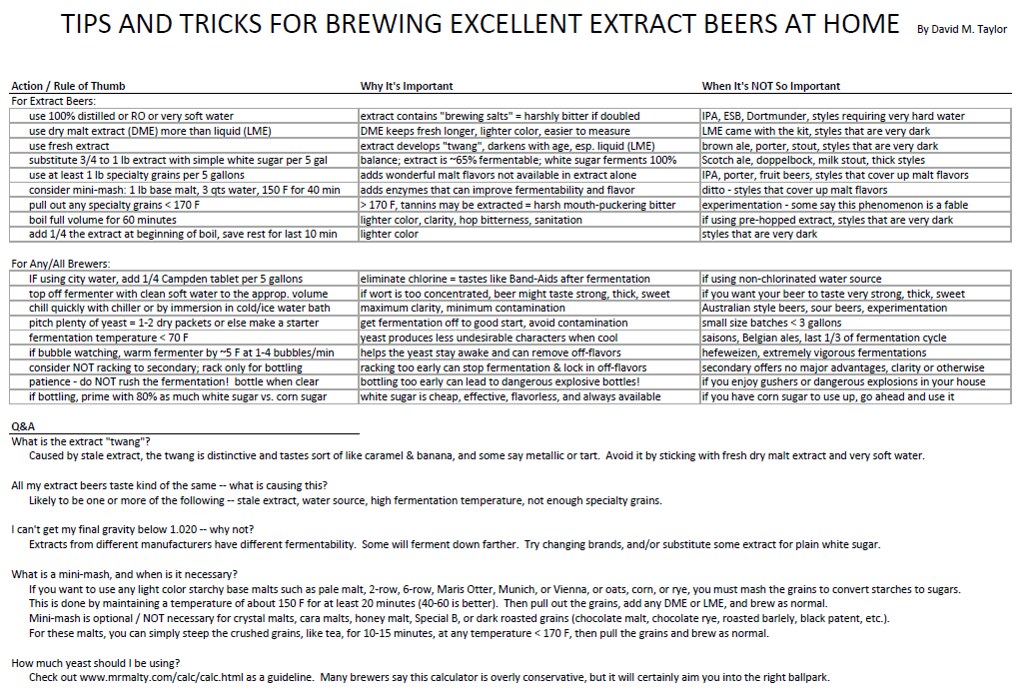

After two weeks I checked gravity and tasted it, now I have a whole new host of problems (well, one of them is the same). I still have the twang, just as much as when I did partials. After talking to my brew partner he mentioned using distilled water. This might be worth investigating because I just use tap.

Also my OG was 1.050 when it should have been closer to 1.060. After 14 days my gravity was 1.020. Not sure where I went wrong. I'm pretty sure the beer is done, but my ABV is not even 4% when the recipe should be 6%.

I did a full boil of 3.5 gallons, LME and DME.

Also my OG was 1.050 when it should have been closer to 1.060. After 14 days my gravity was 1.020. Not sure where I went wrong. I'm pretty sure the beer is done, but my ABV is not even 4% when the recipe should be 6%.

I did a full boil of 3.5 gallons, LME and DME.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)