I am thinking about doing a slightly different approach next time, only using the Thermometer to see when I get up to 70c to add the citric acid, then just gently heat it until it just about starts to simmer, to maybe get a slightly less watery syrup.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

English Ales - What's your favorite recipe?

- Thread starter Puddlethumper

- Start date

-

- Tags

- recipe

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

But the opaque one wasn't boiled as long. It reached 110°C before I noticed then 116°C within minutes. I kept it there for 15 minutes. The translucent one (my usual method) takes at least an hour to start rising above 100°C and quite a while before it reaches 116°C, due to all the water that needs to evaporate. Then it gets held at 116°C for 30 minutes. The different method does seem to have promoted some caramelisation that, ironically, seems to make something more comparable with a Ragus invert. I'll repeat the procedure using unrefined caster sugar at the weekend.You likely got a bit of caramellisation and a higher concentration of sugar in the opaque one since it boiled so long

And again, my girlfriend's father seems to have been right (is that a correct sentence? "Seems to have been"?).But the opaque one wasn't boiled as long. It reached 110°C before I noticed then 116°C within minutes. I kept it there for 15 minutes. The translucent one (my usual method) takes at least an hour to start rising above 100°C and quite a while before it reaches 116°C, due to all the water that needs to evaporate. Then it gets held at 116°C for 30 minutes. The different method does seem to have promoted some caramelisation that, ironically, seems to make something more comparable with a Ragus invert. I'll repeat the procedure using unrefined caster sugar at the weekend.

I will brew tomorrow and it will be English and it will be with an invert made similar to yours!

My suggestion regarding yeast, as your have them on hand: I will use a 50/50 split of direct dry pitch Nottingham/verdant. This should give a nicely crisp finish while controlling the excess verdant fruitiness a bit. Maybe you want to try that as well for your split batch? Should be enough for two batches with half a pack each. I will actually use one pack each, because I don't like to store opened packs anymore.

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

I'm keen to try the Verdant, but I was a bit concerned about the reported fruitiness interacting and masking the subtle characters from the invert. I'll bank some yeast for future use to play with, though. I was thinking of letting it loose on an English IPA on its first outing.And again, my girlfriend's father seems to have been right (is that a correct sentence? "Seems to have been"?).

I will brew tomorrow and it will be English and it will be with an invert made similar to yours!

My suggestion regarding yeast, as your have them on hand: I will use a 50/50 split of direct dry pitch Nottingham/verdant. This should give a nicely crisp finish while controlling the excess verdant fruitiness a bit. Maybe you want to try that as well for your split batch? Should be enough for two batches with half a pack each. I will actually use one pack each, because I don't like to store opened packs anymore.

And, yes, it was a perfectly fine sentence.

Thanks.I'm keen to try the Verdant, but I was a bit concerned about the reported fruitiness interacting and masking the subtle characters from the invert. I'll bank some yeast for future use to play with, though. I was thinking of letting it loose on an English IPA on its first outing.

And, yes, it was a perfectly fine sentence.

That's a good point, plain notti would be probably the best yeast for your comparison.

I'm just finishing a batch of "English" APA, which I brewed with notti and I discovered how much I underrated that yeast. It's such a beauty, only thing is that it's not so expressive, but this can also be a good thing.

Here we go:

200g Rohrohrzucker (equivalent to demarara)

200g Vollrohrzucker (equivalent to dark muscovado)

200g water

a dash of lemon juice

later on, half a teaspoon of baking soda during the end of the heating

I think this beer is going to be nice. Fairly simple bitter, the invert above, 10% flaked barley, 10% heritage crystal, rest pale MO. Goldings for everything half @45 min half @10min. for 30 Ibus. The same amount that went into the boil later dry hopped for 3 days. 1.042 Og is the goal. Yeast is one pack each Nottingham and Verdant, pitched at the same time.

200g Rohrohrzucker (equivalent to demarara)

200g Vollrohrzucker (equivalent to dark muscovado)

200g water

a dash of lemon juice

later on, half a teaspoon of baking soda during the end of the heating

I think this beer is going to be nice. Fairly simple bitter, the invert above, 10% flaked barley, 10% heritage crystal, rest pale MO. Goldings for everything half @45 min half @10min. for 30 Ibus. The same amount that went into the boil later dry hopped for 3 days. 1.042 Og is the goal. Yeast is one pack each Nottingham and Verdant, pitched at the same time.

Attachments

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

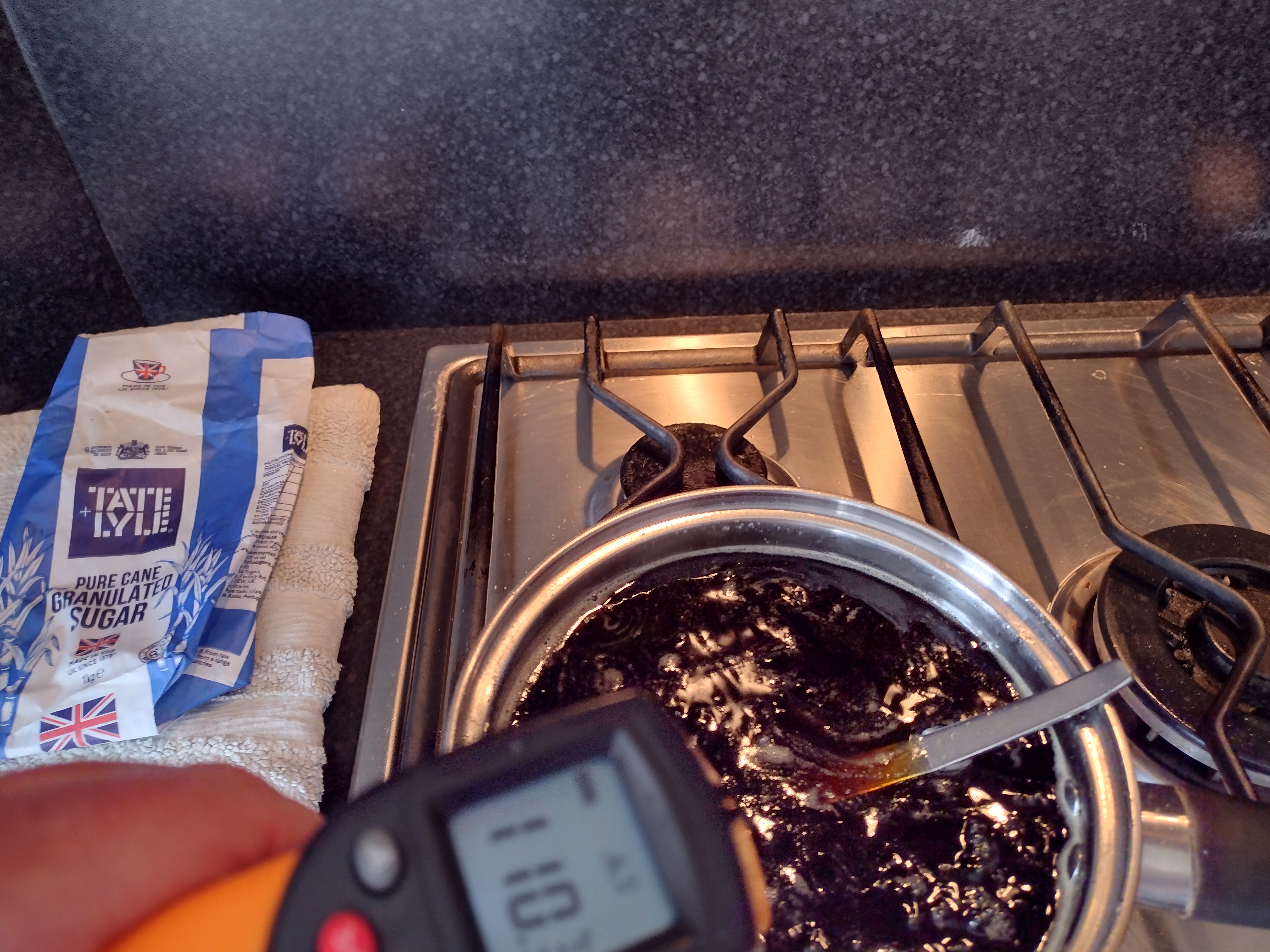

You REALLY want to oversize your pot in which you are boiling the invert when adding the base (baking soda in this case). I transfered the pot into the sink before the base addition, for safety and "girflriend might get mad because of spilled sugary sirup all over the place" reasons, as you can see, it was a good idea.

Btw. Just for future reference, half a teaspoon seems to be too much baking soda. I can taste it now a little bit in the syrup. I added a bit of lemon juice to compensate for it, much better now. Anyway, I'm sure it wouldn't be noticeable in the final beer anyway.

Edit: Brew day done, all cleaned up and the fermenter is in the bath tub to keep it cool during the first two days. Now a "steifer Grog" (dark rum with hot water and a bit of sugar) and let's call it a day.

Edit: Brew day done, all cleaned up and the fermenter is in the bath tub to keep it cool during the first two days. Now a "steifer Grog" (dark rum with hot water and a bit of sugar) and let's call it a day.

Last edited:

Northern_Brewer

British - apparently some US company stole my name

They're one and the same reason, surely?for safety and "girlfriend might get mad because of spilled sugary sirup all over the place" reasons, as you can see, it was a good idea.

Presumably antifoam would work?

Easier/cheaper to ship as well. No worrying about glass containers breaking less space in the truckper pound of sugar.Anyway, I suspect the main reason why Ragus crystallise their invert is to stabilise it. If left as a syrup I imagine it seperates to some unacceptable degree, complicating tailored additions.

Northern_Brewer

British - apparently some US company stole my name

Huh? smaller volumes of liquid sugars always come in plastic buckets, see this at Fuller's (Henry has since moved from Chiswick to be head brewer at Fuller's cooler cousin Dark Star) :No worrying about glass containers breaking.

Picture for color comparison.

Back left is the remnants of #1 syrup made from 1 kg of granulated refined cane sugar by Tate and Lyle in 500ml water acidified to about pH 2 at 70C. The mixture was then simmered and stirred for about 10 minutes, when the mixture began to slightly color and 50g of Demerarar sugar was added. The mixture was removed from the heat and stirred for a few minutes longer, then placed in cold water and partially neutralized.

To the right is Tate and Lyle Golden Syrup and far right granulated Demerara.

Front left Ragus #1, middle Ragus #2, right Ragus #3.

As seen, # 2 and 3 are similar in color, while textures and tastes are different. #3 is soft to cut with taste and texture like fudge, while #1 is hard and sweet and small pieces might break off while cutting, with #2 between them. No practical amount of Ragus #3 will make a dark beer without additions such as heavily kilned malt or Brewer's Caramel.

Attachments

Huh? smaller volumes of liquid sugars always come in plastic buckets, see this at Fuller's (Henry has since moved from Chiswick to be head brewer at Fuller's cooler cousin Dark Star) :

True, still hadn't had my coffee. But the denser solid still presents advantages in transportation and storage

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

I've become a tad skeptical about standardised colour for sugars, especially those we mortals buy from local supermarkets. It's always the brewer's (or anyone's) responsibility to work with what they're supplied. The idea all Demerara, muscovado, molasses or whatever are conveniently standardised across the board is somewhat naive. Having suffered reading the whole thread on another forum, posted by an obsessed compulsive nutter, he's lucky I don't bother myself posting on those forums anymore. It gave me a good laugh, though. Almost comparable to his ridiculing the hydrometer and his so-called 'treatise' on how to type **** about ale condition and beer engines. I think I'd rather nail my knob to the mast of a sinking ship than entertain that deluded muppet.View attachment 768828

Picture for color comparison.

Back left is the remnants of #1 syrup made from 1 kg of granulated refined cane sugar by Tate and Lyle in 500ml water acidified to about pH 2 at 70C. The mixture was then simmered and stirred for about 10 minutes, when the mixture began to slightly color and 50g of Demerarar sugar was added. The mixture was removed from the heat and stirred for a few minutes longer, then placed in cold water and partially neutralized.

To the right is Tate and Lyle Golden Syrup and far right granulated Demerara.

Front left Ragus #1, middle Ragus #2, right Ragus #3.

As seen, # 2 and 3 are similar in color, while textures and tastes are different. #3 is soft to cut with taste and texture like fudge, while #1 is hard and sweet and small pieces might break off while cutting, with #2 between them. No practical amount of Ragus #3 will make a dark beer without additions such as heavily kilned malt or Brewer's Caramel.

I "all but completely" ignore colour, a point I hope to make here. Timothy Taylor's Landlord and Ram Tam, now renamed Landlord Black, are from the same brew, caramel added to the darker version. Also their Golden Best is similarly treated to be Dark Mild. In both cases, the caramel addition influences taste and the drinker doesn't doubt the colour, but there have been, and potentially might still be, some observably dark beers that don't taste dark. One such example I recall from the sixties and seventies was Lorimer's Scotch. Made by Lorimer and Clark in the Caledonian Brewery when owned by Vaux of Sunderland, who sold it as their mid-strength beer in their tied houses. It was dark, black really, but without a highly kilned malt taste, drinking more balanced than many good pale beers. When Vaux sold the Caledonian Brewery to brew Lorimer's Scotch in Sunderland, the beer was the same colour, said to be from the same recipe, but the beer was not the same. Enough said, except to emphasize that while Ragus #1, #2 and #3 are of different colours, that difference is entirely insignificant when compared to their influence in taste.I've become a tad skeptical about standardised colour for sugars, especially those we mortals buy from local supermarkets. It's always the brewer's (or anyone's) responsibility to work with what they're supplied. The idea all Demerara, muscovado, molasses or whatever are conveniently standardised across the board is somewhat naive. Having suffered reading the whole thread on another forum, posted by an obsessed compulsive nutter, he's lucky I don't bother myself posting on those forums anymore. It gave me a good laugh, though. Almost comparable to his ridiculing the hydrometer and his so-called 'treatise' on how to type **** about ale condition and beer engines. I think I'd rather nail my knob to the mast of a sinking ship than entertain that deluded muppet.

That on the left 87.1% pale plus 4.3% each of crystal 130 EBC, homemade #1 syrup and homemade #3 syrup.

On the right 76% pale, 5.9% flaked maize, 5.7% torrified barley, 6.5% Ragus #3 block and 5.9% homemade #1 syrup.

The effect of the crystal malt is plain to be seen, but not that of #3 Ragus block.

Thank you, good to know that.@cire

We just invert the sugar for the bees with some citric acid in the water and add a teaspoon of honey to stop it crystallising.

Never heard of beekeepers in our UK bee club or here in Wellington using invertase. I'm sure some do though if you've heard that.

It was a homebrewer who had previously kept bees who suggested using that process for making brewing sugar. That conversation led to a retired brewery consultant chemist and also a homebrewer, extracting invertase from a packet supermarket bread yeast. If my memory serves me correctly, his findings were that inversion by this method could take several days.

https://www.philipharris.co.uk/product/biology/human-body/enzymes/invertase-50ml/b8a01806

Seems a right faff.Thank you, good to know that.

It was a homebrewer who had previously kept bees who suggested using that process for making brewing sugar. That conversation led to a retired brewery consultant chemist and also a homebrewer, extracting invertase from a packet supermarket bread yeast. If my memory serves me correctly, his findings were that inversion by this method could take several days.

https://www.philipharris.co.uk/product/biology/human-body/enzymes/invertase-50ml/b8a01806

Interestingly if you feed in the summer best to give raw cane sugar as granules then the bees are less likely to swarm away. In spring and winter feed them the inverted sugar syrup. Concentration / ratio varies for those times.

My wife is the Queenbee, hence I'm the worker bee doing the heavy lifting, building etc. Not allowed to be a drone which she says do nothing really except hope to mate but otherwise a waste of space and drain on resources.

Again my thanks for your information, in future I'll amend my script when recounting my journey into homemade invert sugar. I've got to say the final consensus was using invertase was a right faff. The bee advisor gave me some Borage seeds to plant in my garden for bees. The Brewing Consultant/Chartered Chemist/homebrewer analysed several of my early attempts at inverting sucrose to find them badly flawed. From those, he did trials varying both pH and timings at a light simmer and gave me his findings, which compared closely to the method given in Graham Wheeler's first book.Seems a right faff.

Interestingly if you feed in the summer best to give raw cane sugar as granules then the bees are less likely to swarm away. In spring and winter feed them the inverted sugar syrup. Concentration / ratio varies for those times.

My wife is the Queenbee, hence I'm the worker bee doing the heavy lifting, building etc. Not allowed to be a drone which she says do nothing really except hope to mate but otherwise a waste of space and drain on resources.

McMullan

wort maker

- Joined

- Dec 22, 2015

- Messages

- 2,566

- Reaction score

- 3,461

Slightly off topic, but interesting. Sucrose, the main product of photosynthesis, is among the most abundant sugars on the planet. And invertase among the most abundant enzymes. Like most living things, bees do synthesise their own invertase. Am In right thinking bee keepers just use inverted sugar solutions to help get hives through winter, rather than a staple for the bees?@cire

We just invert the sugar for the bees with some citric acid in the water and add a teaspoon of honey to stop it crystallising.

Never heard of beekeepers in our UK bee club or here in Wellington using invertase. I'm sure some do though if you've heard that.

@McMullan

It depends on how scrupulous they are, if they keep taking all of the honey from a hive then they need to feed " sugar " to supplement the loss, some do take brood as well if there is honey on the frame.

Less commercial / more ethical or hobby beekeepers will bridge feeding gaps when food ( read nectar ) is not so abundant or if there's been bad weather ie several days of rain during a time they'd be out and about. This of course does help to preserve the hives reserves so that some can be harvested later, but bees will starve if cold and lack of food. Here in NZ the bees seem to be out all year wheras in England where it gets cold they tend to be dormant during the cold months, all balling up to keep warm and supping honey for energy to make heat.

It depends on how scrupulous they are, if they keep taking all of the honey from a hive then they need to feed " sugar " to supplement the loss, some do take brood as well if there is honey on the frame.

Less commercial / more ethical or hobby beekeepers will bridge feeding gaps when food ( read nectar ) is not so abundant or if there's been bad weather ie several days of rain during a time they'd be out and about. This of course does help to preserve the hives reserves so that some can be harvested later, but bees will starve if cold and lack of food. Here in NZ the bees seem to be out all year wheras in England where it gets cold they tend to be dormant during the cold months, all balling up to keep warm and supping honey for energy to make heat.

Back home I have access to my notes determining acid required to achieve pH 2.2 in 500ml of my tapwater for inversion. From 2015, but show how bad my memory currently is as more than double the amount of acid I thought and gave in an earlier post.

1 litre of tapwater with 260ppm alkalinity as CaCO3 measured by Salifert KH kit, with 0.88ml of HCl measured pH 4.37. If end of alkalinity is assumed at pH 4.4, this would indicate HCl is slightly below 6 molar.

Half of that water volume required an addition of 0.65ml of the same HCl to achieve pH 2.2. The other half was then used to make invert with 1Kg of cane sugar, 0.65ml of HCL added at 70C.

Sorry for the previous incorrect information and I would advise those who can, should take readings using their water.

1 litre of tapwater with 260ppm alkalinity as CaCO3 measured by Salifert KH kit, with 0.88ml of HCl measured pH 4.37. If end of alkalinity is assumed at pH 4.4, this would indicate HCl is slightly below 6 molar.

Half of that water volume required an addition of 0.65ml of the same HCl to achieve pH 2.2. The other half was then used to make invert with 1Kg of cane sugar, 0.65ml of HCL added at 70C.

Sorry for the previous incorrect information and I would advise those who can, should take readings using their water.

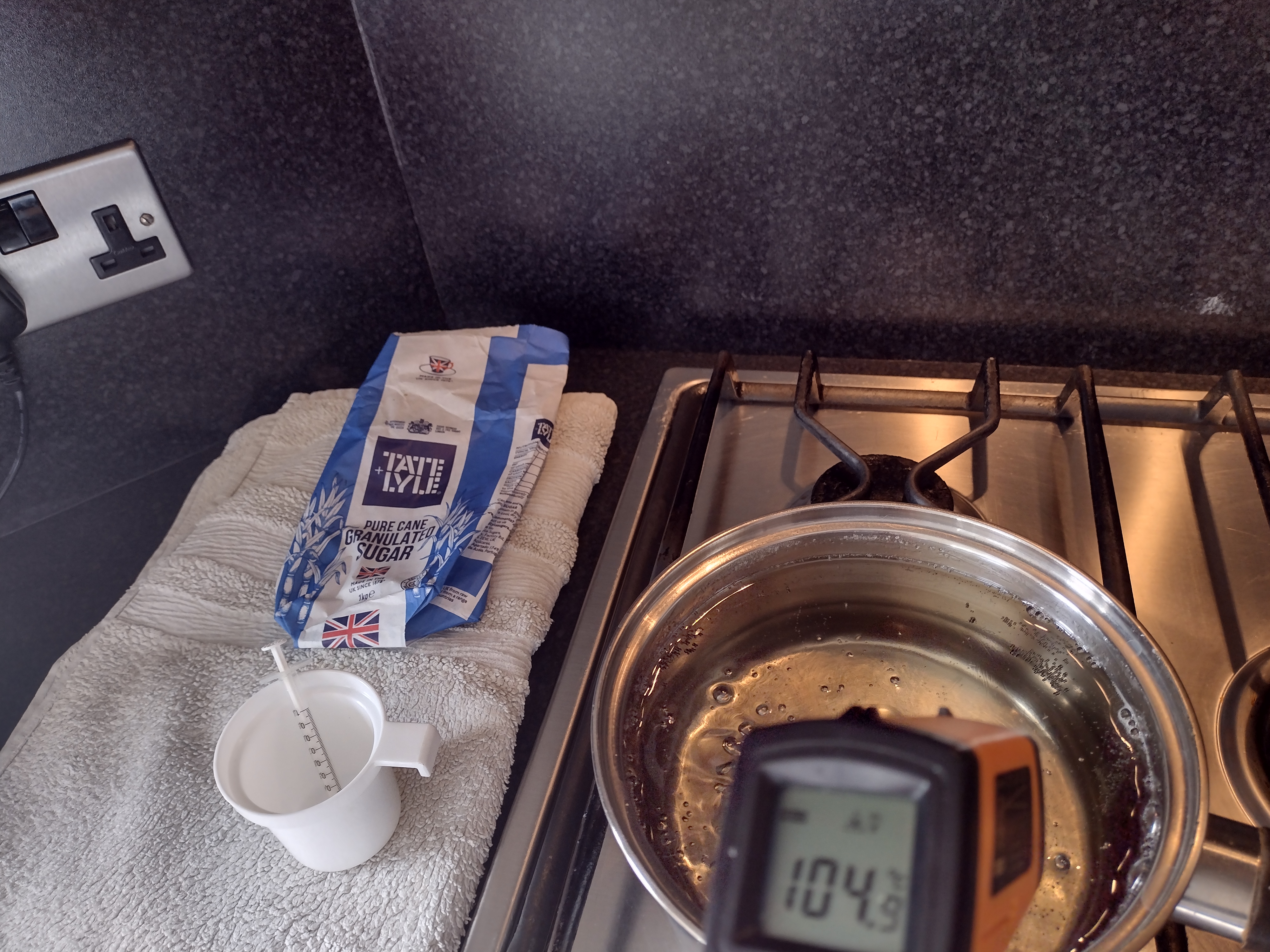

1 Kg pure cane granulated sugar in 500ml of tapwater acidified to pH 4.4 for zero alkalinity. Most sugar is undissolved.

At 70C most sugar is seen to be dissolved. 0.65ml of 6 molar HCl at the ready in the syringe.

Acid added and the mixture cleared as stirred, now seen beginning to simmer.

After simmering for a short while the sugar begins to take on a yellow tinge, I assumed this occurs as inversion nears completion.

50g of black treacle added, plus 25g of demerara stirred in, then heat and stirring stopped.

1 mol of sodium bicarbonate will neutralize 1 mol of hydrochloric acid.

0.65ml of 6 molar HCl contains 6 X 0.00065 = 0.0039 mols of HCl.

1 mol of sodium bicarbonate weighs 84.1g, so 0.0039 mols weighs 84.1g X 0.0039 = 0.328g.

Suggest 0.35g sodium bicarbonate addition to neutralize acid addition.

Not quite the last, hopefully another half dozen pints to go.

This was my from first attempt at Big Lamp Bitter, a sort of fill-in brew after 5 months of inactivity, chosen because it was local brew I have drank, and a simple recipe with all ingredients to hand. It isn't an old recipe, first brewed in 1982, but still very much a run-of-the-mill British Bitter.

The recipe used is from Graham Wheeler's BYOBRA, with brew-length extended a little with some homemade invert #1 and #3, and a few extra hops to compensate for the extra volume.

Mine had 150 EBC crystal malt.

I just placed the kegs in my first ever kegerator build a moment ago, 2 large kegs with TT Landlord inspired premium bitter and northern style nut brown ale, and a 12L keg of a basic English oat stout.

Naturally carbed in the kegs and the kegerator is set to keep 11-12c ofc...

Will hook up the gas tomorrow and in a few days I can become a functional alcoholic!

Gonna keg a dark mild tomorrow.

My inverts seem to have recrystallised a bit, gonna try the tsp of honey and let it get up to a simmer and hold it there for a few minutes next time, to ensure full dissolving and inversion.

Naturally carbed in the kegs and the kegerator is set to keep 11-12c ofc...

Will hook up the gas tomorrow and in a few days I can become a functional alcoholic!

Gonna keg a dark mild tomorrow.

My inverts seem to have recrystallised a bit, gonna try the tsp of honey and let it get up to a simmer and hold it there for a few minutes next time, to ensure full dissolving and inversion.

Send picture of Kegerator! or beer.

@DuncB

I got done assembling everything yesterday, the kegs had already been inside and getting chilled for 24hrs by then.

Ofc I could not keep myself from doing a test pour and that made me realise that doing cask levels of carbonation is probably not really feasible in a keg setup. Had primed them to about 1.7 vol and had the gas on the pressure equivalent to that and it resulted in a very slow pour, pulled up the pressure to 13 psi wich is equal to about 2vols at the temp i keep the kegs at.

Not cask levels of carbonation but still not fizzy so all is good, next time I'll prime to 2vols.

I pulled a few small glasses of bitter and even though the last started to clear it tasted a little yeasty and generally "green" so a few days to a week of cool conditioning before I start drinking from it is probably not a bad idea.

Gonna make some nicer cable arrangements, paint the fridge antracite gray and switch the tap handles to dark oiled oak ones during the summer while I am on long vacay and paternity leave, me and the missus have about 2.5 months free simultaniously this summer.

I got done assembling everything yesterday, the kegs had already been inside and getting chilled for 24hrs by then.

Ofc I could not keep myself from doing a test pour and that made me realise that doing cask levels of carbonation is probably not really feasible in a keg setup. Had primed them to about 1.7 vol and had the gas on the pressure equivalent to that and it resulted in a very slow pour, pulled up the pressure to 13 psi wich is equal to about 2vols at the temp i keep the kegs at.

Not cask levels of carbonation but still not fizzy so all is good, next time I'll prime to 2vols.

I pulled a few small glasses of bitter and even though the last started to clear it tasted a little yeasty and generally "green" so a few days to a week of cool conditioning before I start drinking from it is probably not a bad idea.

Gonna make some nicer cable arrangements, paint the fridge antracite gray and switch the tap handles to dark oiled oak ones during the summer while I am on long vacay and paternity leave, me and the missus have about 2.5 months free simultaniously this summer.

Attachments

Northern_Brewer

British - apparently some US company stole my name

Just as general advice, if you buy European malts and to a lesser extent hops, then it's a good idea to lay in some generous stocks in the next couple of months, as the price rises down the line are going to be huge - like 50+%, I've seen commercial brewers complaining that it's like them paying retail prices!

Makes sense as grain prices are up a lot but malt also uses a lot of energy in roasting/drying, and gas prices on the Continent in particular have gone crazy due to recent events, but it's bad enough in the UK.

Makes sense as grain prices are up a lot but malt also uses a lot of energy in roasting/drying, and gas prices on the Continent in particular have gone crazy due to recent events, but it's bad enough in the UK.

I think I'll just have to suck up the price increase when I next buy malt. If I bought any now I think my wife would kill me. I bought 2 each of pilsner and ale malt before Christmas expecting to sell half of them on but then friend said he had enough. I reckon the other odds and sods were another 25 kg so unless I can build an underground grain store I'll have to wait.

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 18

- Views

- 2K

- Replies

- 27

- Views

- 5K