iijakii

Well-Known Member

I'd say it's cause he recirculates and has a false bottom (not a braid) so he doesn't have to worry about channeling, so the hose works fine.

If you have 2 inches of water over the grain bed there's no reason you'd be getting channeling. Worst case the hose may make a divot on the surface due to water flow, if you keep that flow down there shouldn't even be that.

Oracle said:Jeff,

Thanks for the guide and personal attention to this long-running thread. I know you posted a "typical" brew day in a post many moons ago, but could you give a couple of recipe examples and walk through the process step-by-step? Folks new to brewing (like myself) would benefit, especially as we learn how to scale 5 gallon recipes down to 3 or 3.5 gallons.

I was inspired to put a system together based on your design and am very happy with it so far, but have only used it twice (once for an extract recipe and once for an all grain recipe). The latter was a challenge because I jumped the gun and bought the ingredients for a 5 gallon recipe (milled and mixed at the local store), so couldn't easily cut it down. Worked out pretty well anyway, I just had to add water as the boil proceeded to avoid over-filling my boiler/kettle.

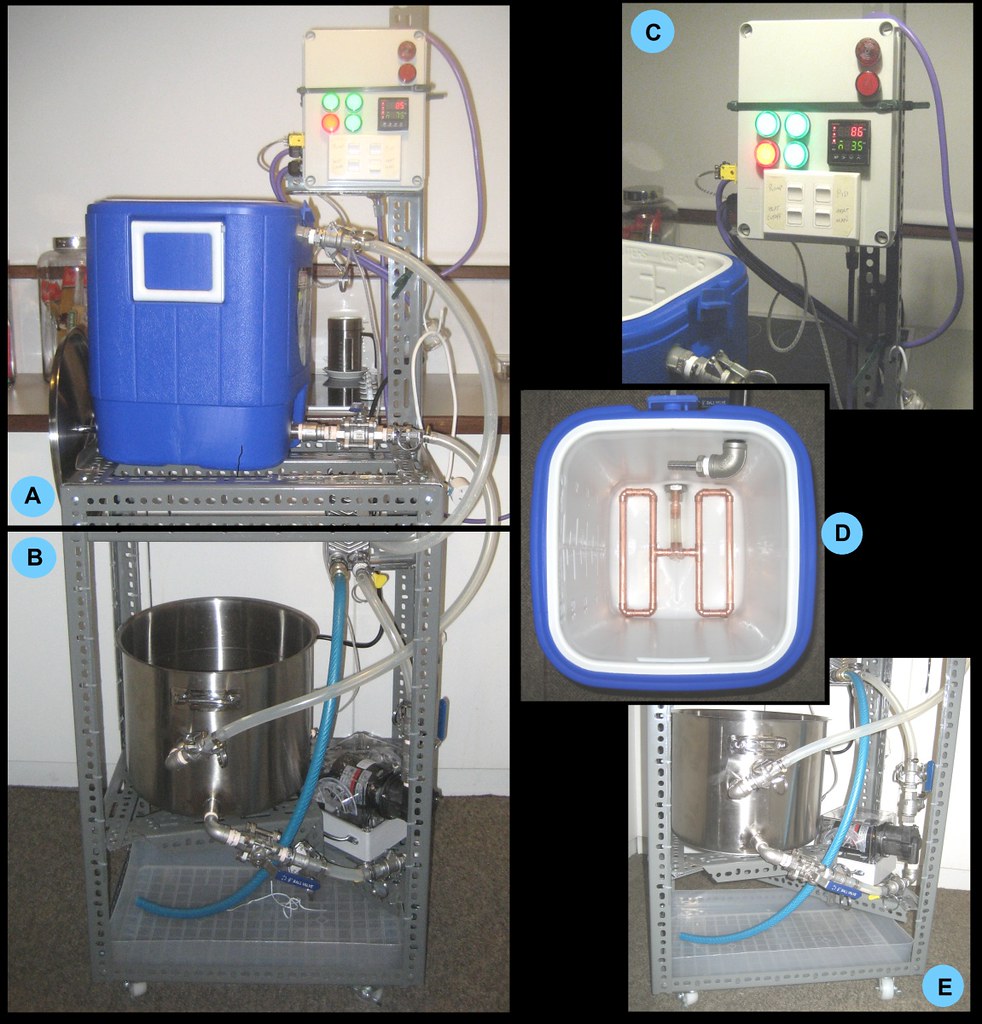

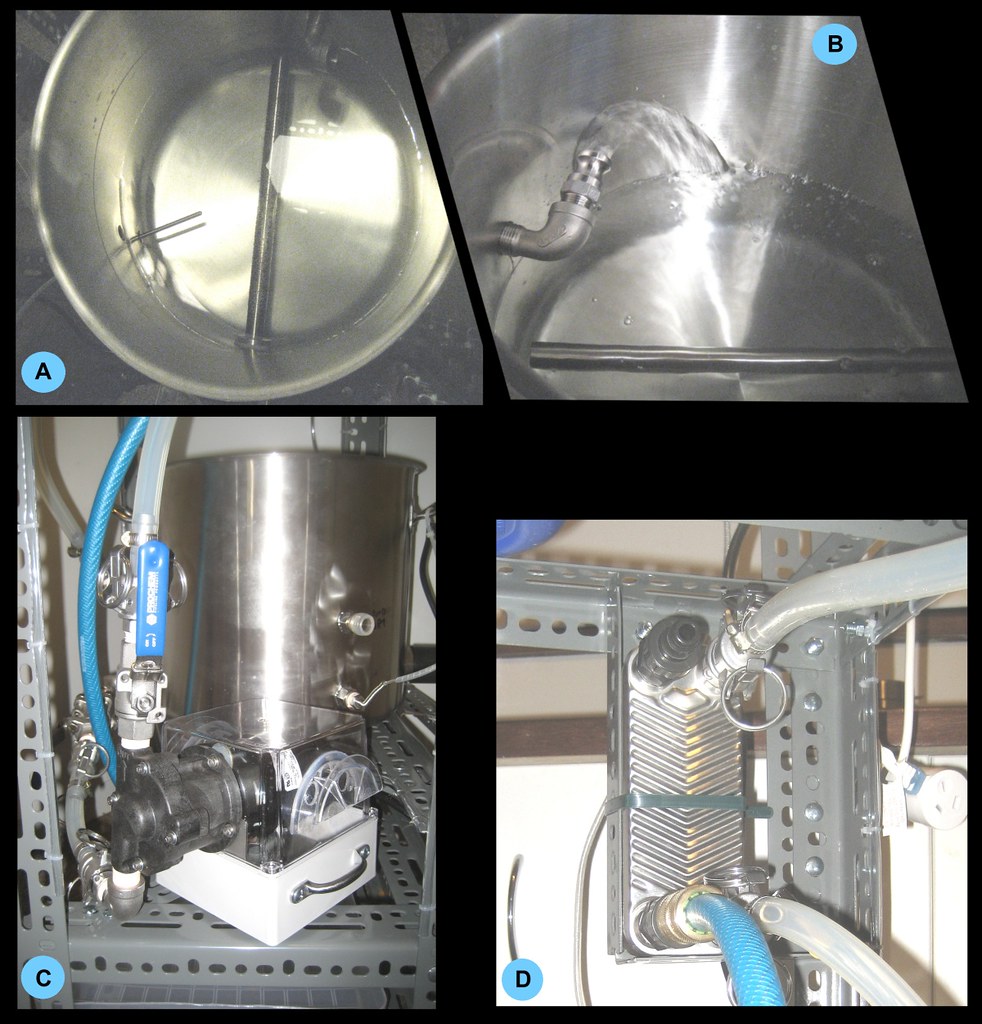

Here are a few picks of my system:

Interesting. I've always kind of suspected this, but have always gone with the standard crush from my HBS. I've been wanting to buy my own crusher so I can have better control over this process. Can you give me some guidance on how best to set up a roller mill for this finer crush?I recirculate fairly slowly; perhaps 1 quart per minute through a keggle false bottom.

One thing I have found with the recirculating no-sparge system is that crush on the grain matters far more. I started malt conditioning and crushing finer and got far closer to the theoretical efficiency of the system. I am getting about 97% conversion efficiency which is driven by the crush, and then lauter efficiency is governed by system losses and the pre-boil gravity of the beer. A combination of conversion and lauter efficiency gives you your brewhouse efficiency. Braukaiser has a great write up on this if you are interested.

Joshua

OK, I'm new to grain brewing. Never have done it yet. Like to build this system. I have a dumb question but do you ever have clogging of hops in the lines and pump when pumping from the kettle through the chiller? Also, do you have to run your cooled wort from the brew pot through some kind of strainer into your fermenter? How long do you leave the cooled wort in the kettle to settle all the particulates prior to draining? Would be nice to see some recipes that have been used in this exact same design. I really don't understand a lot of the technical aspects of formulation, efficiancy and whatever, but I can easily follow a recipe and time table to make a brew. I have only done extracts on the stove and thought they all were good until I had a bottle of a home brewed all grain. Just a dumb retired fireman and haven't found a beer I didn't like.

OK, I'm new to grain brewing. Never have done it yet. Like to build this system. I have a dumb question but do you ever have clogging of hops in the lines and pump when pumping from the kettle through the chiller? Also, do you have to run your cooled wort from the brew pot through some kind of strainer into your fermenter? How long do you leave the cooled wort in the kettle to settle all the particulates prior to draining? Would be nice to see some recipes that have been used in this exact same design. I really don't understand a lot of the technical aspects of formulation, efficiancy and whatever, but I can easily follow a recipe and time table to make a brew. I have only done extracts on the stove and thought they all were good until I had a bottle of a home brewed all grain. Just a dumb retired fireman and haven't found a beer I didn't like.

No dumb questions in there. Replying to a few of the points-

Hops don't tend to clog pumps and lines. Hops and grains will both clog filters in the wrong situations. I drop my hops into cheap filter bags, which allows them plenty of exposure to the wort but minimizes the mess a bit.

By all means go with the Countertop Brutus if you're convince that's how you want to go (I love my system) but I felt it was really helpful to do my first few all grain batches in a system where I wasn't worried so much about pumps and figuring out new equipment. The Stovetop All-Grain Brewing thread can usually be done almost entirely with things you have on hand.

As far as what ends up in the fermenter - if you minimize most of the gunk (let it settle for a few minutes, then pump/dump/siphon out) anything that does make it in there will settle if you give it adequate time after fermentation.

Good luck with everything.

I read through half the thread. I have one buring question my infantile mind can not figure out:

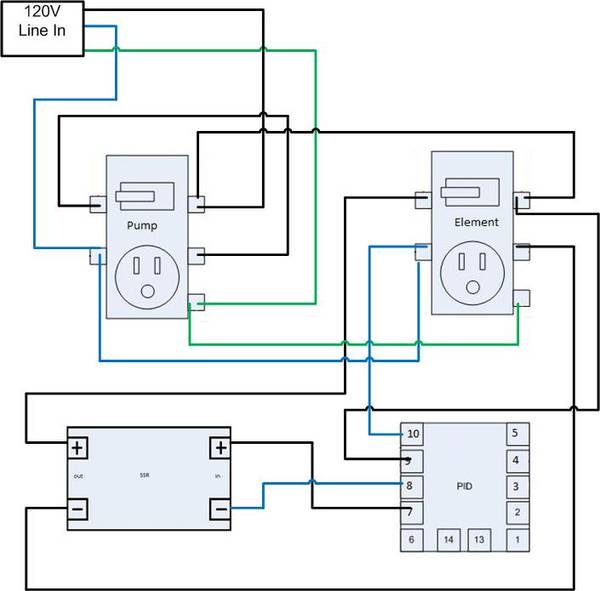

What does the PID do? Does it turn off the element when the mash in temp is hit? Does it turn on the element when the temp gets too low during recirculation?