Could RIMS tube users weigh in on the sizing of their heating element?

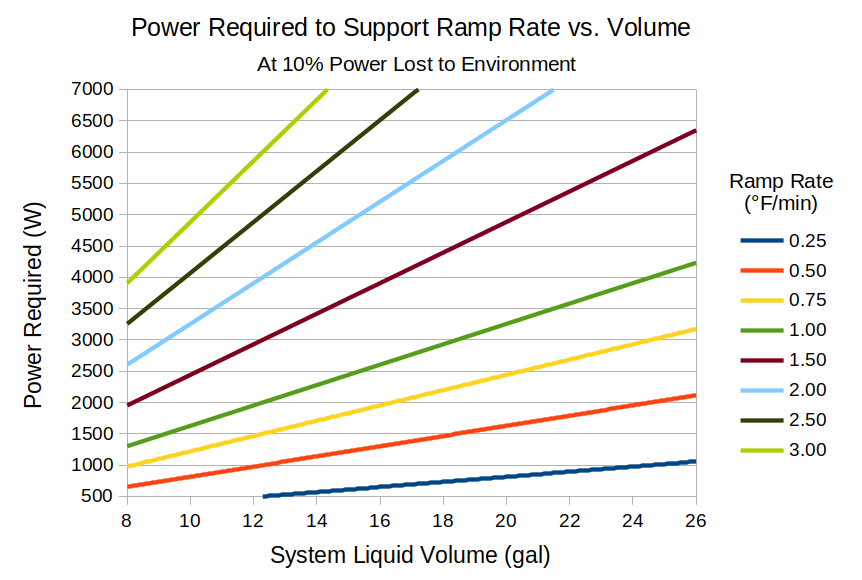

I use a 1500W (120V) element with a PID controller, with 120V input (mainly for maintaining temperature when it's cold).

I acknowledge that the element size probably depends on what one is doing with the heater. Some scenarios might be:

Alternatively, what is the minimum rating for elements for step-mashing (just asking about user stories; there is no "spec")? Scorching is always a concern, of course.

Do folks rely more on the element rating for anti-scorch wort safety, or is the controller the more important system component?

It would be great to hear from more seasoned RIMS users on these issues.

I use a 1500W (120V) element with a PID controller, with 120V input (mainly for maintaining temperature when it's cold).

I acknowledge that the element size probably depends on what one is doing with the heater. Some scenarios might be:

- Simply maintaining temperature during recirculation of a single-infusion mash

- Step mashing

Alternatively, what is the minimum rating for elements for step-mashing (just asking about user stories; there is no "spec")? Scorching is always a concern, of course.

Do folks rely more on the element rating for anti-scorch wort safety, or is the controller the more important system component?

It would be great to hear from more seasoned RIMS users on these issues.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)