jds

Well-Known Member

We all (well, most of us, anyhow) know the importance of aerating wort prior to pitching yeast. As a KISS brewer, I don't oxygenate. My usual aeration method has been either carboy shaking or a wire whip before transferring to the fermenter. Until yesterday.

The LHBS proprietor suggested the following trick, and it works great:

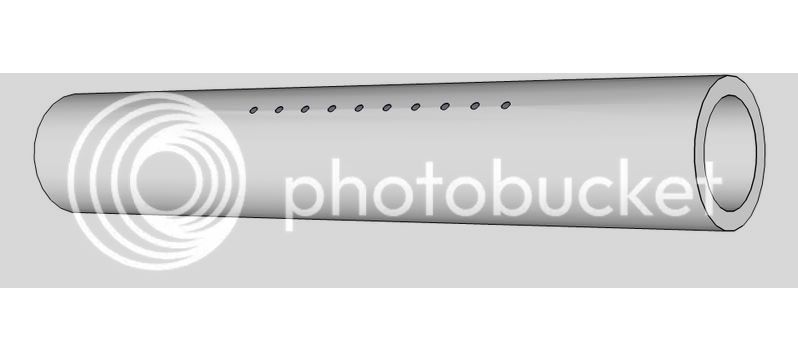

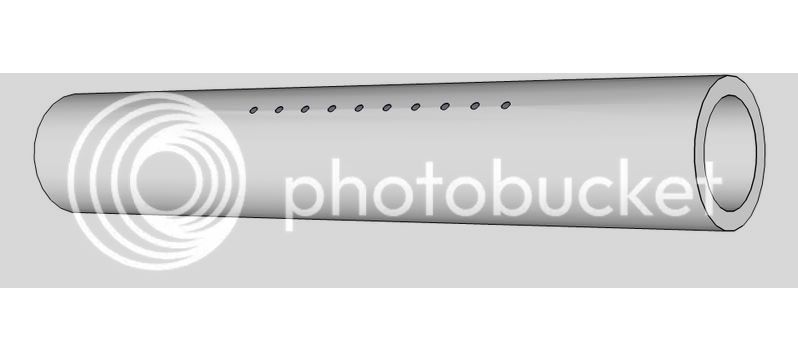

My racking cane ended up looking something like the below:

Except that I twisted the cane a little bit so all the holes weren't along the same axis.

I used it yesterday when transferring a 1.055 OG cream ale to the fermenter. The little holes serve to suck in air, which makes tiny bubbles in the stream of wort. Tiny bubbles = more surface area = more oxygen transfer (and memories of Don Ho, too)

By putting this widget right at the top of my 6.5G carboy, I generated a layer of froth about 3" thick after racking. The package of dry notty I pitched with had started to make foam within six hours of pitching at 3 PM yesterday, and is pushing gas out the 1-1/4 inch blowoff tube this morning. I'm sold. This widget is part of my routine now.

The LHBS proprietor suggested the following trick, and it works great:

- Take a six-inch length of racking cane

- Heat a straightened paperclip in a flame

- Use the hot paperclip to melt a series of small holes through the wall of the racking cane.

- Insert racking cane into transfer tubing when transferring cooled wort to fermenter.

My racking cane ended up looking something like the below:

Except that I twisted the cane a little bit so all the holes weren't along the same axis.

I used it yesterday when transferring a 1.055 OG cream ale to the fermenter. The little holes serve to suck in air, which makes tiny bubbles in the stream of wort. Tiny bubbles = more surface area = more oxygen transfer (and memories of Don Ho, too)

By putting this widget right at the top of my 6.5G carboy, I generated a layer of froth about 3" thick after racking. The package of dry notty I pitched with had started to make foam within six hours of pitching at 3 PM yesterday, and is pushing gas out the 1-1/4 inch blowoff tube this morning. I'm sold. This widget is part of my routine now.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)