RiverCityBrewer

Well-Known Member

What specific model of the ESP-32 series are they? Were they working before yesterday?

Yeah they have been working and in use for a few months. Pics of them attached.What specific model of the ESP-32 series are they? Were they working before yesterday?

Are you using Hysteresis for FV1 and FV2?Hi All, I should be grateful if you could help me please with guidance on how I can configure my two Fermenters (FV1 & FV2) each with a 12v 3 wire motorised valve activated via an individual 12v relay module so at the same time my single glycol pump (common to both FV’s) can be switched on at the same time a FV calls for cooling?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

As I said, I am not sure what the "value" is tied to, but hopefully, it is the state of the Hysteresis element. There is no state attribute of a Hysteresis element.Hi Oakbarn, Thanks for your help, which is much appreciated and I was planning to use Hysteresis elements for FV1 and FV2 and in a dry run scenario this works ok for the vales, but it is the glycol pump that I and struggling with, and thanks for the script and I’ll try this out.

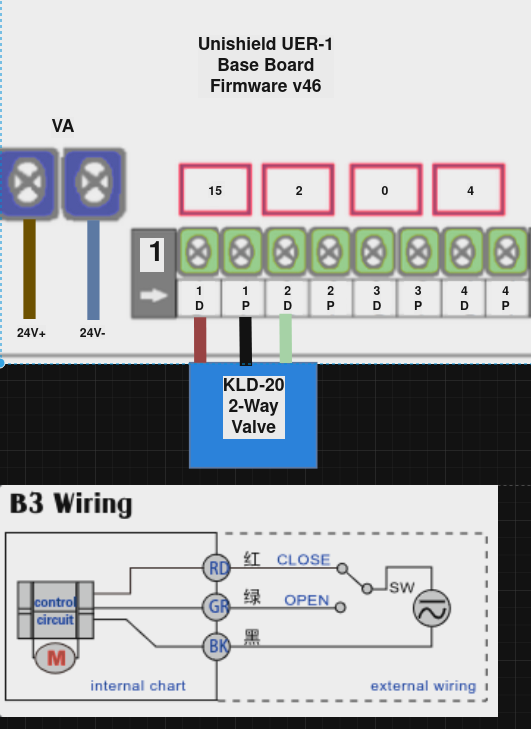

Thanks again @RiverCityBrewer, 2-way valves (KLD20S) are operating as expected:Just apply 24v to the open/close contacts according to your build pinout.

I'm not sure if there is a more elegant way to do it; however, you can write some scripts that run on a loop to achieve what you're asking about I believe. Example:Hi, For my Fermenting Control ? Process, is there a way that I can create a single "Switch" via Device Elements that will be placed on the Workspace screen to give me an option to press "Start" / "Stop" which will then activate / control any elements (if disabled or not), as well as starting the corresponding scripts? Thanks.

That switch is not enabledHave you clicked the Enable Service button to ON?

No, the release option is unavailable as well.Can you "release" the URL for that assigned port then "reserve" again and see if you have the ability to enable service?

Solved it from this thread: netsh.exe: Error 87No, the release option is unavailable as well.

I'm not sure if there is a more elegant way to do it; however, you can write some scripts that run on a loop to achieve what you're asking about I believe. Example:

[ACTIVATELOOP]

wait "Active Switch" State == on

"Device Element" enabled = true

start "Device Element Script"

goto "ACTIVATELOOP"

And in a separate script:

[DEACTIVATELOOP]

wait "Active Switch" State == off

"Device Element" enabled = false

stop "Device Element Script"

goto "DEACTIVATELOOP"

Global variables don’t count up or down. You can change the display name though.Global Timers

Tried searching and could not find the answer. (still very new to scripting) My goal is to have a cluster of hop addition countdowns that all start when I start the boil process.

I'm able to create a timer and set the time and display name via a script no prob but while reading about it, it sounded like the experts are using globals as timers when creating multiple timers. I got as far as setting the time value for the global but got stuck.

In addition to setting the time, is it possible to set the display name and whether it counts up or down as well as start it via a script?

Thanks! I think I will revise my screen to do just that. Use that same timer and repurpose it for each step....especially now that I know I can change the display name if I want to.Global variables don’t count up or down. You can change the display name though.

I use one timer element for boil/mash step time. One timer element is the easiest way in my opinion. I set the value of the timer element using a global variable in a script. The same script watches the timer element’s value (wait or if statement) for the end condition. This is either <= O (end of step) or the hop addition time (also a global variable). One can use global variables or script variables. I use a combination of both depending on what I am trying to do. Start with one type and play with it till you get it to function the way you want. Then refine/over complicate it later.

I use one timer for almost every thing. I have been working on a complex hop script that add hops in groups (at the same time). It is a work in progress.Global variables don’t count up or down. You can change the display name though.

I use one timer element for boil/mash step time. One timer element is the easiest way in my opinion. I set the value of the timer element using a global variable in a script. The same script watches the timer element’s value (wait or if statement) for the end condition. This is either <= O (end of step) or the hop addition time (also a global variable). One can use global variables or script variables. I use a combination of both depending on what I am trying to do. Start with one type and play with it till you get it to function the way you want. Then refine/over complicate it later.