First brew going well and still in process. Doing a daisy cutter clone with the 600 micron mash basket.

View attachment 610503

View attachment 610504

View attachment 610504

View attachment 610503

Last edited:

Good looking boil.

Mate tells me their server is down and will be rebooted on Monday. My machine hasn’t been able to update.

Yes... almost 2 weeks and I quit keeping track of the number of reboots after 50, about half wired and half wireless.

Yes... almost 2 weeks and I quit keeping track of the number of reboots after 50, about half wired and half wireless.

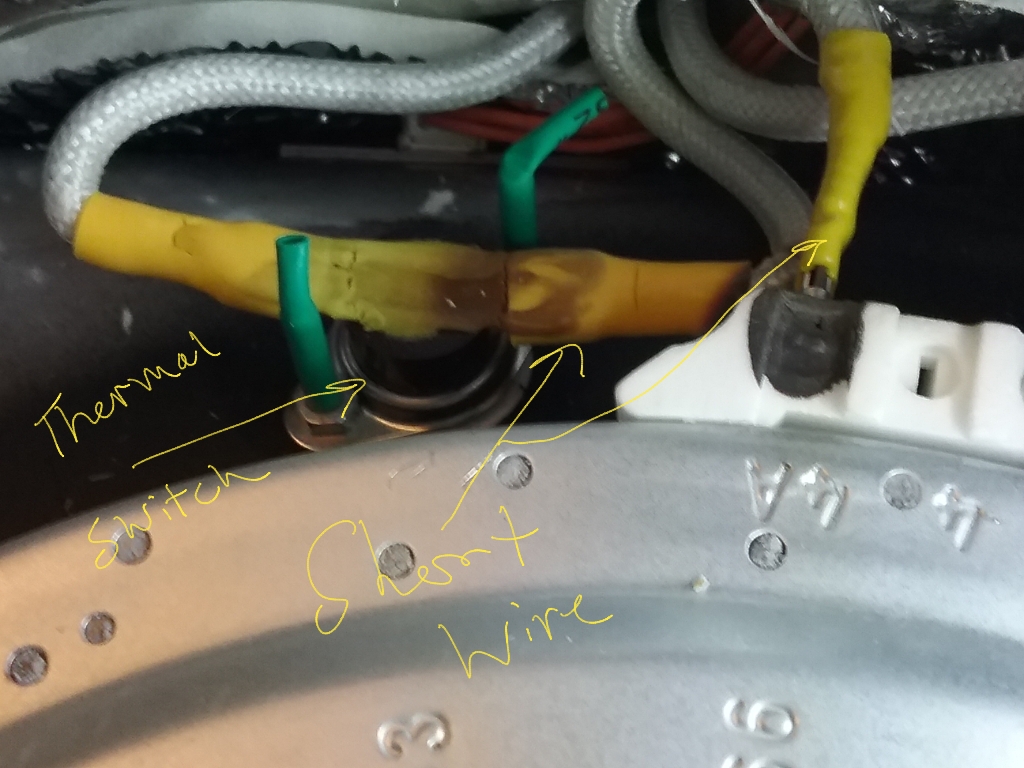

I stand corrected: what crumbled away was a piece of melted silicone, the terminal below is still intact. Does anyone have a good picture of the wiring to the thermal switch and the heating element? Thanks!

Thank you this helps! I need to put new crimp connections on my short wire.View attachment 611450

Here is a start.... have to look through pics

It is important to cut the wire till you find a unaffected by heat section. Please read conversations Harkin and I had a month ago, maybe around page 30, I explain everything about this mod. Nice to see Brewie are putting fans on new machine, this is the only way to keep terminals above maximum spec temperature.Thank you this helps! I need to put new crimp connections on my short wire.

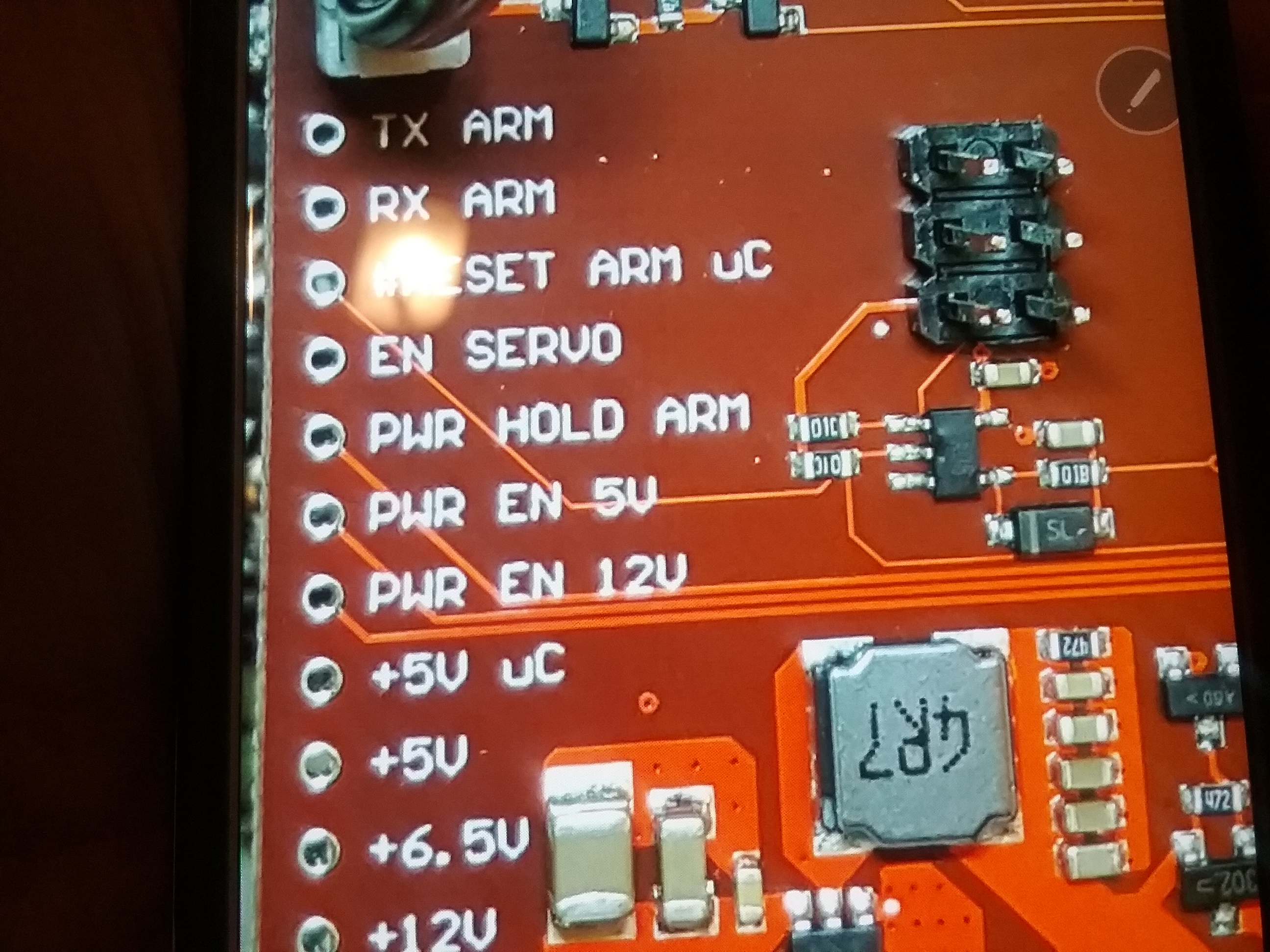

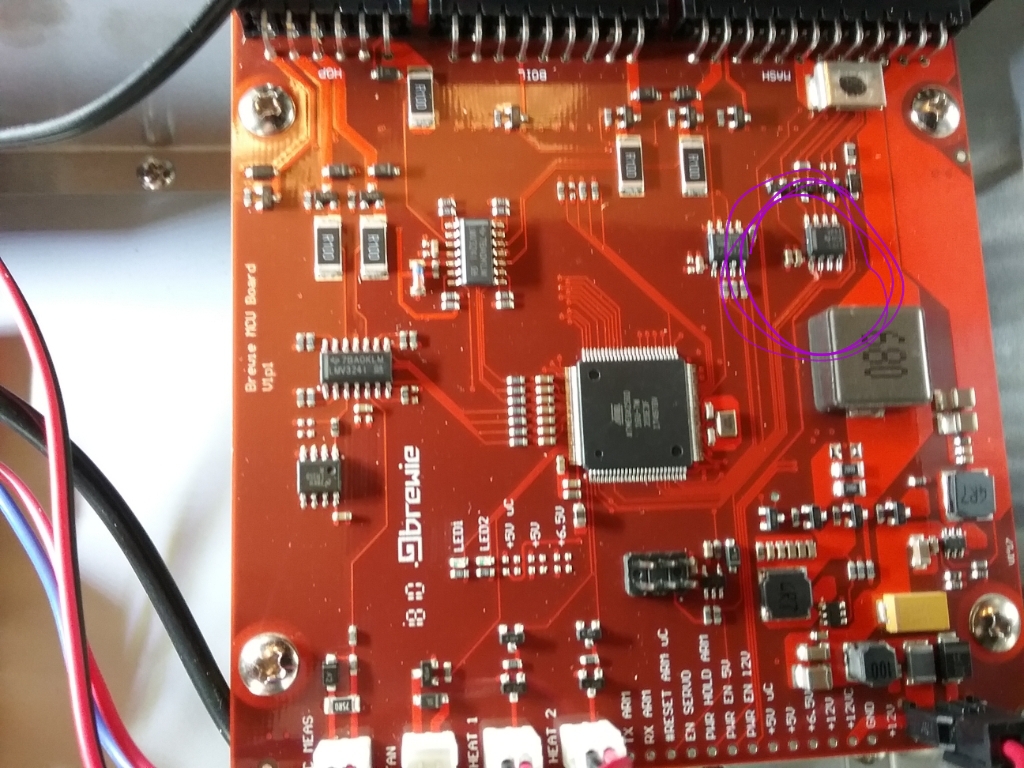

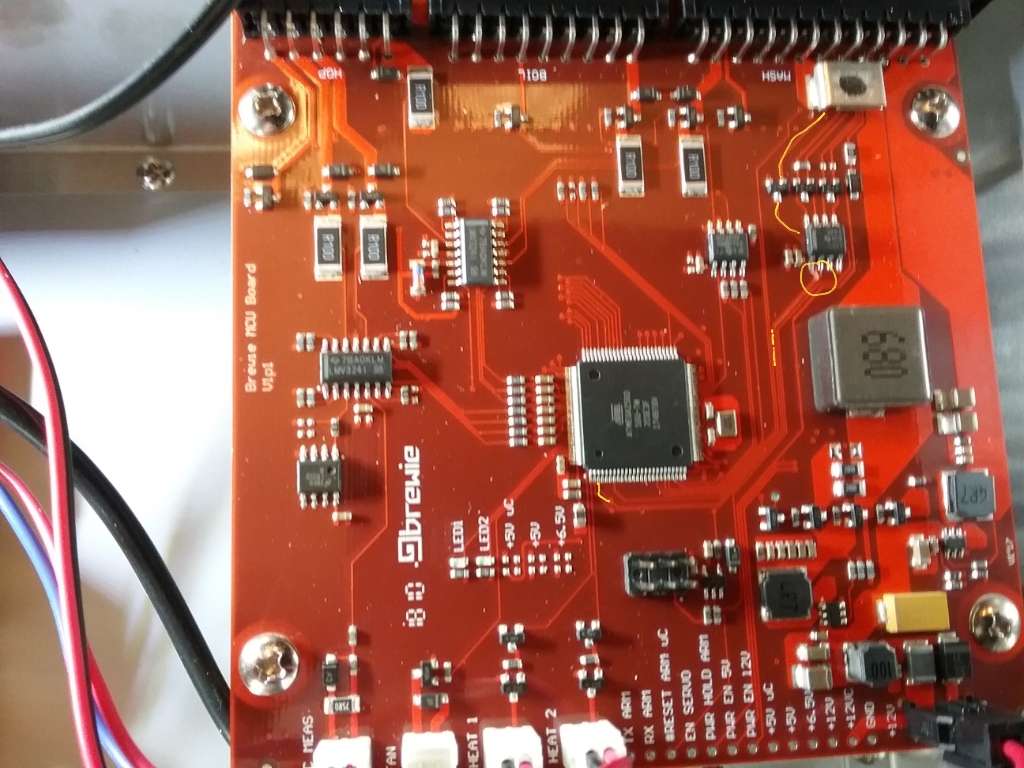

This chip looks like driving 3 mosfet, so it is an output chip, probably driving valves or something else, unlikly to cause your software issueAfter examining the board with a microscope I think I have a nick in the etching that is causing my problem..... manufacturing again. I also think there is solder where it shouldn't be.

It is important to cut the wire till you find a unaffected by heat section. Please read conversations Harkin and I had a month ago, maybe around page 30, I explain everything about this mod. Nice to see Brewie are putting fans on new machine, this is the only way to keep terminals above maximum spec temperature.