Hello everyone

I have a question regarding my brewie i hope you can help me with...

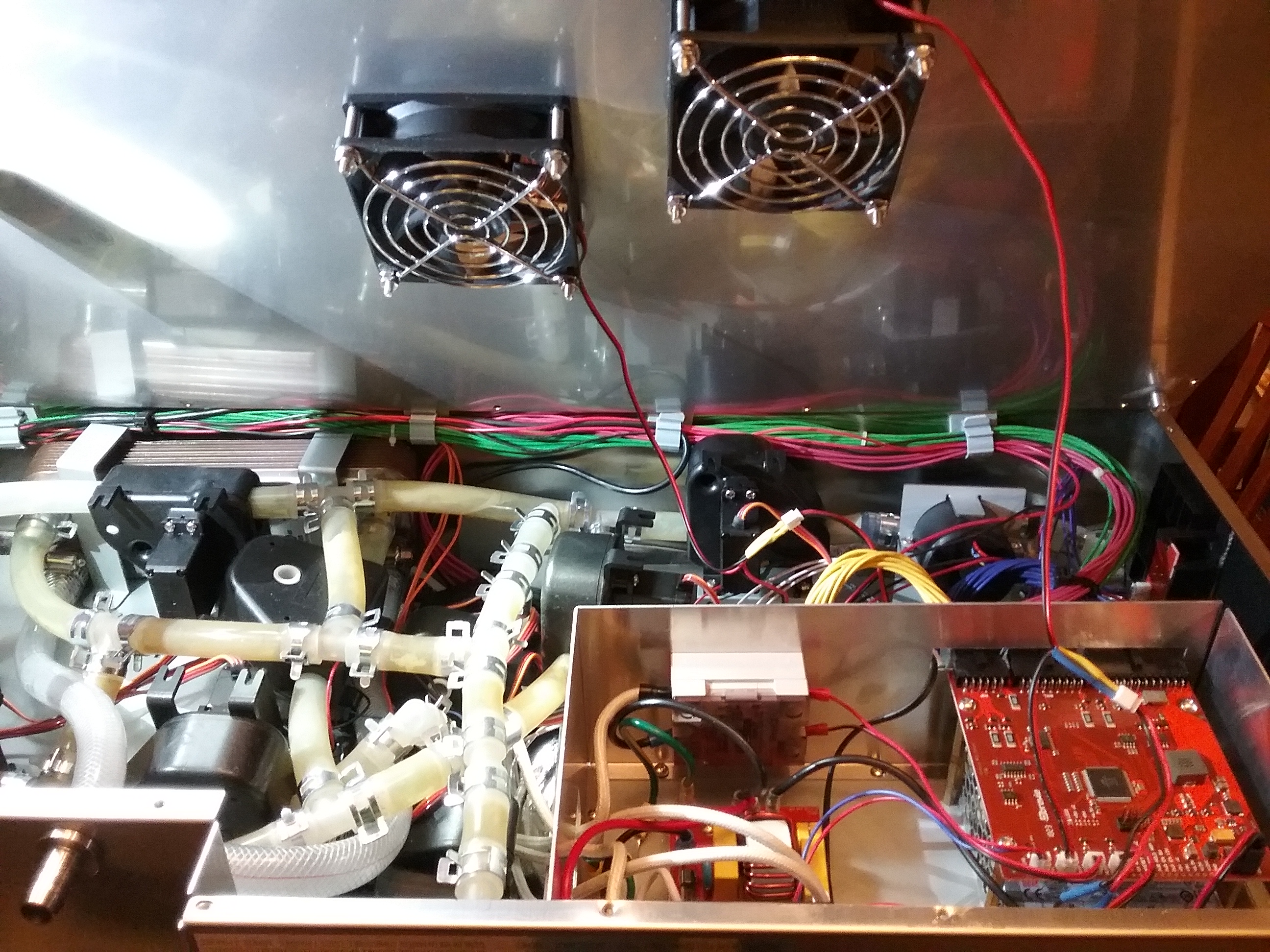

I read on the Brewie website that during the cooldown i could turn down the water flow to reduce the was amount used, since the waste water is very cold. I tried this at my last brew, but when i turned down the inlet water flow, my brew/beer/mash started to flow out of the water waste hose, mixed with water?!? Directly into my drain - i tried to turn it even more off, and it seems like it was pure Beer comming out, can anyone tell me how this is possible? And what a out when there is pressure on, is there comming water into the Beer then :-0??

I had the same thing, if you are comfortable taking your machine apart take the bottom off and check to see your hoses are not twisted. Otherwise contact tech support and they will help you out. You may have a "valve" that is not closing all the way.

Another thing, when you calibrate your brewie do you do it with or without the false buttom + hop tanks inside the brewie?

According to instructions remove hop cages and false bottom

I had some issues that it tales too much water in, resultant in a massive boilover.... I spoke with Máté, that told me to run the test recipe, and measure the height in the middle of the boil tank. It should be 11.3cm, when i test it i get from 11.5 to 12cm.

Máté also told me the test recipe is a 10-10 liter test, but the recipe of the brewie tells the machine to fill it up with 8 liters, I asked Máté but havent heard from him.

He will get back to you, recalibrate your machine. The Brewie+ uses a pressure sensor instead of weight sensor so it is pretty accurate and can tolerate more movement etc

If you are unsure about water amounts you can manually measure your input and measure the height then run the test program. You can change the test recipe to your needs or to what Máté says.

FYI this is a brand new Brewie, we have used it 4 time last week

)

First time we started it up and did the “short cleaning” it turned off completely in the beggining of the cleaning. We tried around 5 times, and then it stopped. Now it seems to work.

The machine was probably not updated all the way to the latest software.

Note to everyone!

You must make sure your machine is updated to the latest software version! You may have to reboot it several times for it to get there. It WILL NOT update to the latest software all at once it only updates to the next version available from what is already on the machine each time it is turned on. Current version 3.1.1 as of Feb 26 2019. Check on brewie.org for latest version number.

Last thing!

I am going to brew a Grimbergen clone soon, but in this i need to add Dextrose and liquid syrup in the end of the boil. Can you do this with the hop tanks somehow or should i just add it manually

??

Do it manually. Hops tanks are for hops and spices and things like that. I would not try to add dry malt, malt extracts, honey, liquid malt extracts to them.

Update: I just found a video from Brewie that says you can add sugar to the hop cages to adjust your OG.

Additional note: the hop cages will float when they are being used under certain circumstances and it could cause a mess. Be sure to have your lid closed if you are not right there paying attention.

Hope you can help me, + all tips are welcome.

(Picture of the “too much water” added)

Best Regards Nicolai (from Denmark)

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)