Here are some useful ideas I have cobbled together mostly from this forum to augment my boil kettle for use with BIAB. Let me reiterate, I can claim none of these ideas as my own. The purpose of this little thread is to simply put the ideas all in one place so that others looking to do BIAB might benefit. There are no novel approaches here. Nonetheless, here it is.

Pictured below

• Megapot with its calibrated thermometer at the 3.5 gallon mark on the kettle and a 2-piece stainless steel ball valve with a camlock.

• Internally, a makeshift dip-tube using a 90 degree elbow and a hose barb is shown. This allows complete draining of the pot if desired.

• To allow easier and more precise volume measurements to be made the pot was etched in ¼ gallon increments. The Megapot comes etched at 1 gallon intervals. The additional markings allow measurements to an accuracy of 1/8 gallon with ease.

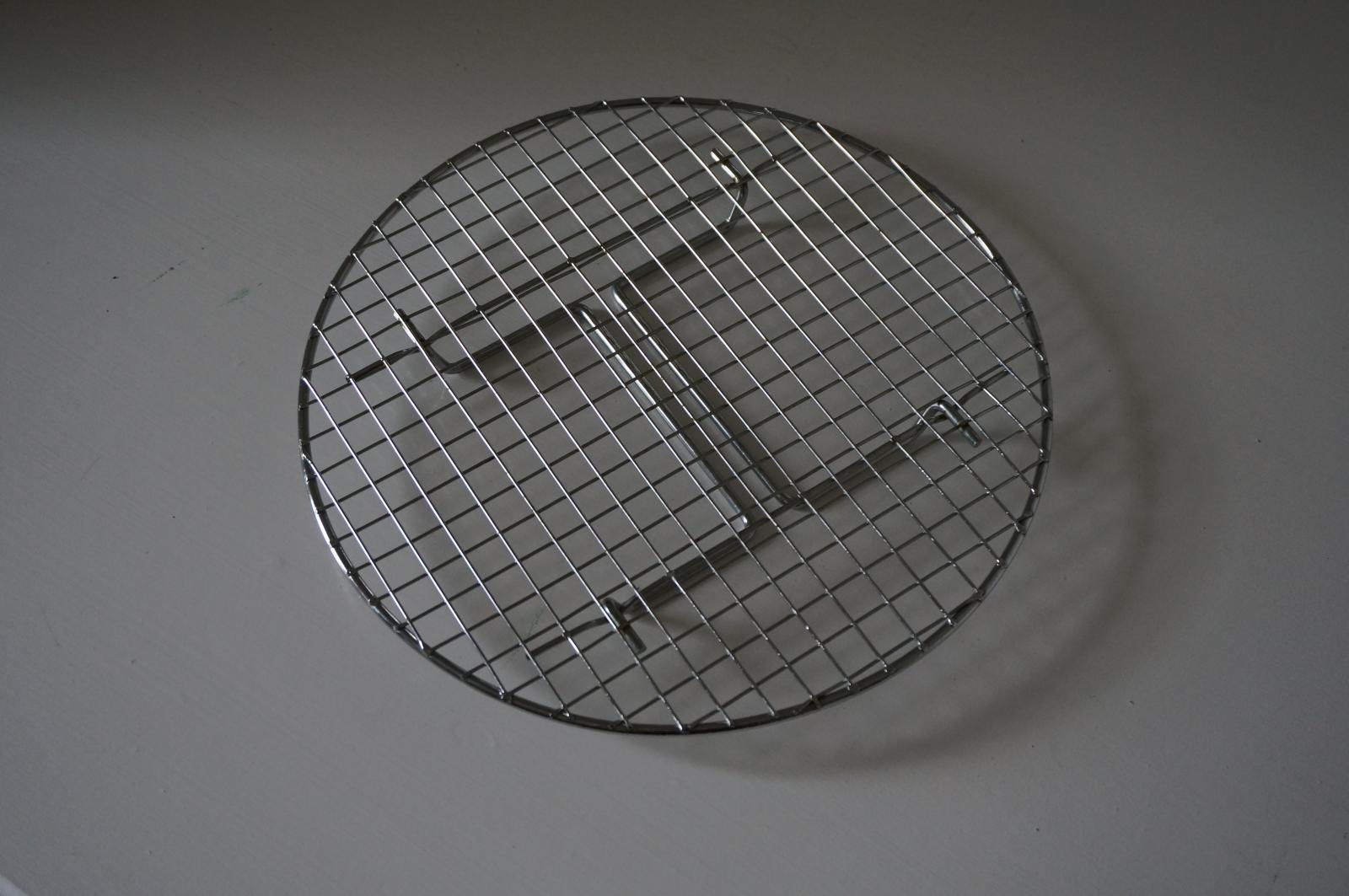

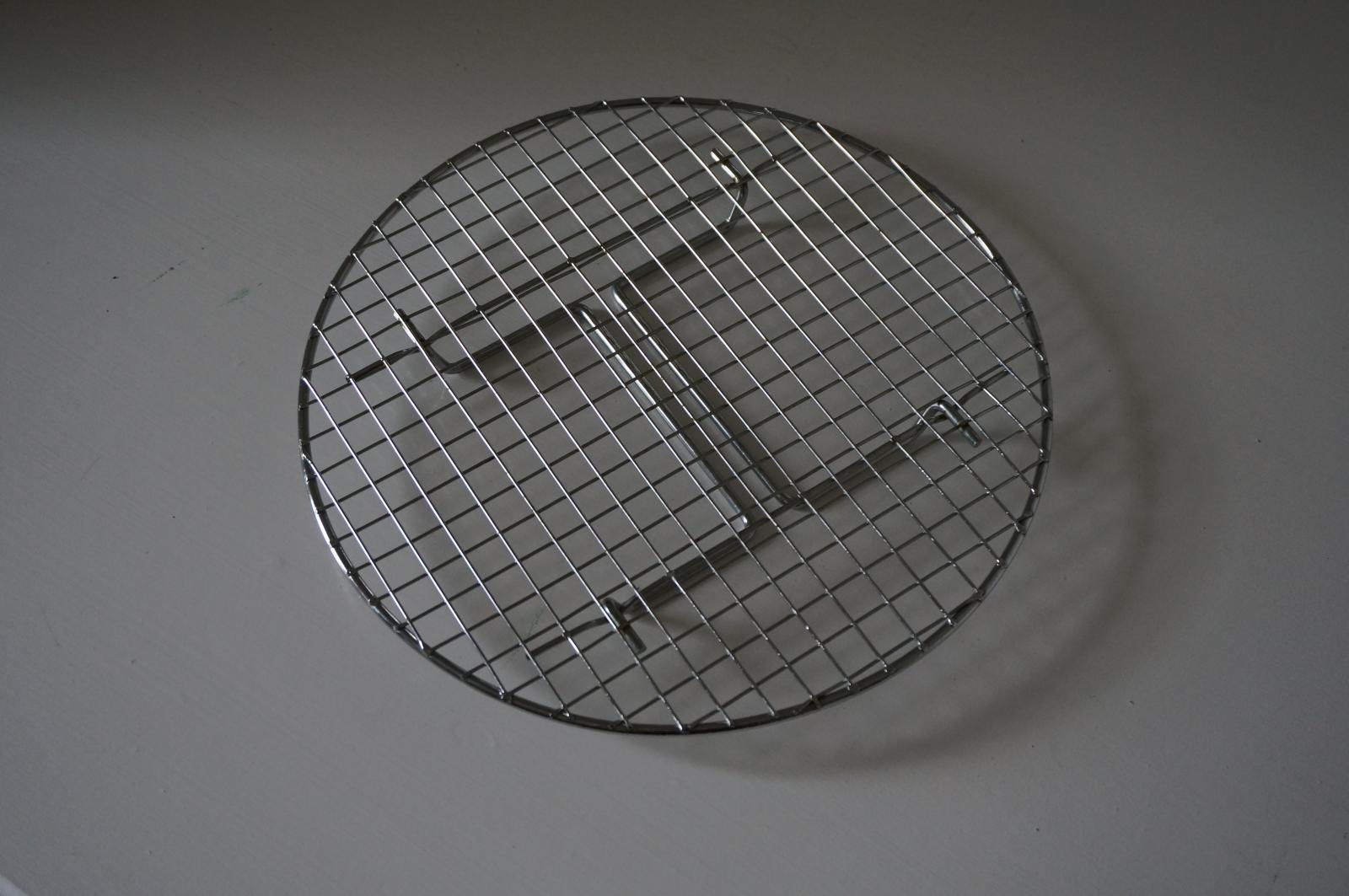

• A cooling rack is placed on the bottom of the pot following preparation of the strike water volume and additions and prior to bag placement. This protects the bag from scorching during application of heat to the base. (NB: I have not tried my process without the rack so I cannot say for certain that this risk exists.)

• An insulation jacket was tailored to fit the pot using Reflectix, Reflectix foil tape and <$1 of hardware to secure the 4 layers together. This is placed onto the pot after doughing-in. It seems to work very well. Minimal heat loss is noted over the course of a 60-90 minute mash. The jacket and bag are secured with bungee cords.

• Clamps. During cooling via a plate chiller I recirculate the sweet wort back to the pot. The use of two simple clamps secures the silicone tubing safely to the pot. The hose can be positioned to create a whirlpool potentially resulting in a more rapid cooling to 65F. This is far from an ideal way to create a whirlpool but does seem to work reasonably well. The clamps also largely eliminate the risk of the hose popping out of the pot and spraying hot wort everywhere. This safety consideration is especially important during the last 15 minutes of the boil.

Pictured below

• Megapot with its calibrated thermometer at the 3.5 gallon mark on the kettle and a 2-piece stainless steel ball valve with a camlock.

• Internally, a makeshift dip-tube using a 90 degree elbow and a hose barb is shown. This allows complete draining of the pot if desired.

• To allow easier and more precise volume measurements to be made the pot was etched in ¼ gallon increments. The Megapot comes etched at 1 gallon intervals. The additional markings allow measurements to an accuracy of 1/8 gallon with ease.

• A cooling rack is placed on the bottom of the pot following preparation of the strike water volume and additions and prior to bag placement. This protects the bag from scorching during application of heat to the base. (NB: I have not tried my process without the rack so I cannot say for certain that this risk exists.)

• An insulation jacket was tailored to fit the pot using Reflectix, Reflectix foil tape and <$1 of hardware to secure the 4 layers together. This is placed onto the pot after doughing-in. It seems to work very well. Minimal heat loss is noted over the course of a 60-90 minute mash. The jacket and bag are secured with bungee cords.

• Clamps. During cooling via a plate chiller I recirculate the sweet wort back to the pot. The use of two simple clamps secures the silicone tubing safely to the pot. The hose can be positioned to create a whirlpool potentially resulting in a more rapid cooling to 65F. This is far from an ideal way to create a whirlpool but does seem to work reasonably well. The clamps also largely eliminate the risk of the hose popping out of the pot and spraying hot wort everywhere. This safety consideration is especially important during the last 15 minutes of the boil.