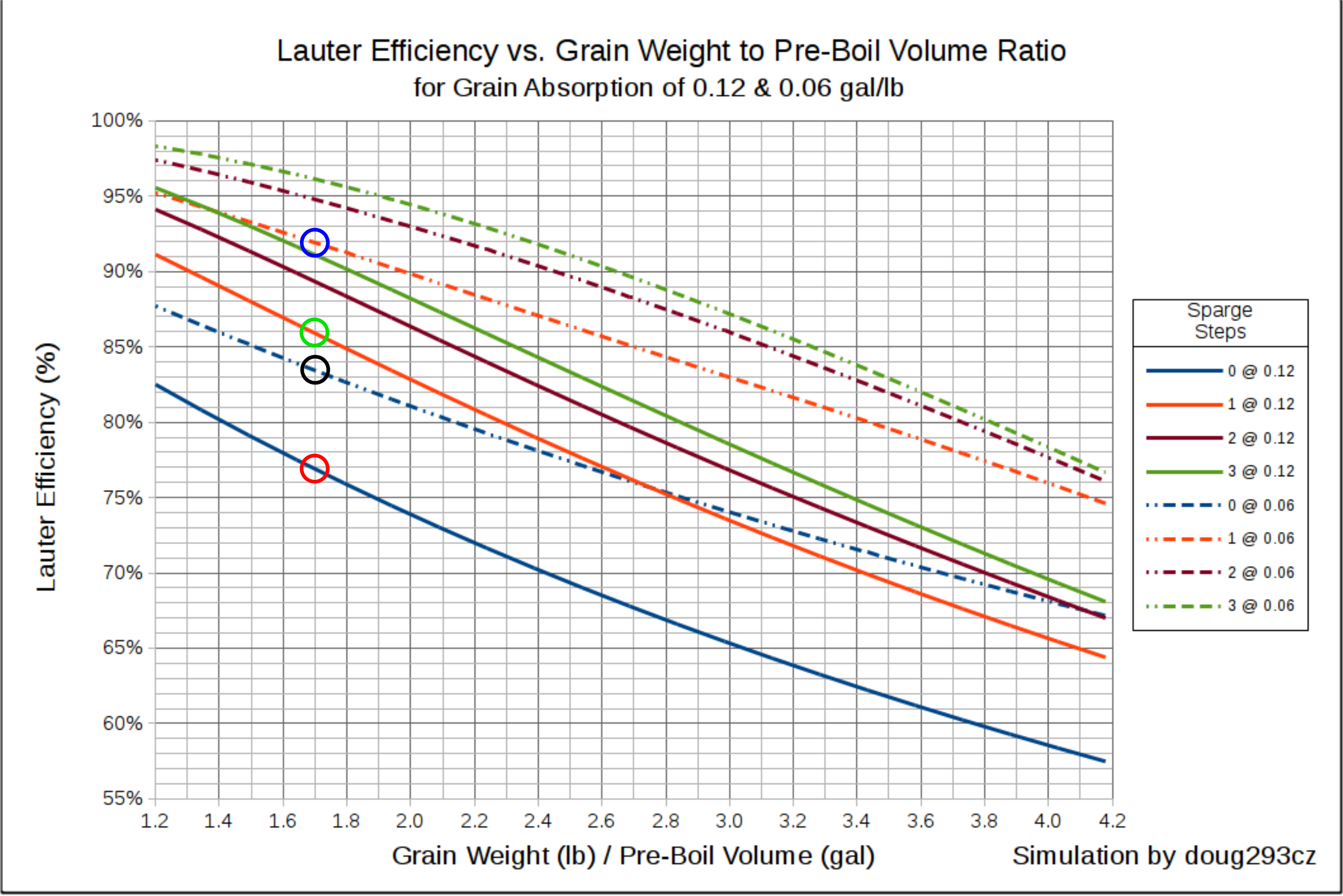

The effects of sparging vs. squeezing vs. doing both when batch (or no) sparging have been calculated based on simple dilution theory by many folks, including me. I have put together a chart that shows how they all fit together.

The assumptions are as follows:

- Conversion of starch to sugar has stopped (either by achieving 100% conversion, or doing a mash out) prior to any wort being run off.

- Wort in the mash vessel has been completely homogenized prior to each run off step (initial and sparge.)

- The grain absorption rate (squeezing level) is the same after every run off step.

The chart plots lauter efficiency vs. the ratio of grain weight (in lbs) to the pre-boil volume (in gal), as this makes the chart independent of batch size. If your conversion efficiency is 100% then mash efficiency will equal lauter efficiency. If conversion is less than 100%, then mash efficiency will be proportionately lower than lauter efficiency. For sparges, each sparge volume is the same as the first runnings volume, until the grain bill increase causes the mash thickness to reach 0.9 qt/lb, at which point strike water remains constant and the sparge water is divided equally among all sparge steps. The calculations for the chart are for the case of 0 undrainable volume in the mash vessel (typical for BIAB.) The solid lines represent the case of no squeezing, which in a typical MLT results in a grain absorption rate of close to 0.12 gal/lb. The dashed lines represent the case of squeezing down to a grain absorption rate of 0.06 gal/lb, typical of a moderately aggressive BIAB squeeze. A BIAB bag applies a slight squeeze on it's own, without any additional action by the brewer, and depending on drain time may give a grain absorption rate of 0.10 - 0.11 gal/lb.

View attachment 567498

Let's look at what the calculations tell us about a case with a 6.5 gal pre-boil volume and an 11 lb grain bill (ratio = 11 lb / 6.5 gal = 1.7 lb/gal)

Case 1: No Sparge, No Squeeze - Grain absorption = 0.12 gal/lb. The

RED circle shows this point on the chart. Lauter efficiency is: 76.9%, and the pre-boil SG is: 1.045 (not on chart, but from spreadsheet.)

Case 2: No Sparge, Squeezed - Grain absorption = 0.06 gal/lb. The

BLACK circle shows this point on the chart. Lauter efficiency is: 83.4%, and the pre-boil SG is: 1.049.

Case 3: 1 Sparge, No Squeeze - Grain absorption = 0.12 gal/lb. The

GREEN circle shows this point on the chart. Lauter efficiency is: 85.9%, and the pre-boil SG is: 1.050.

Case 4: 1 Sparge, Squeezed - Grain absorption = 0.06 gal/lb. The

BLUE circle shows this point on the chart. Lauter efficiency is: 91.9%, and the pre-boil SG is: 1.054.

If we look at Case 3 vs. Case 1, and Case 4 vs. Case 2, sparging always beats no sparging for the same level of squeezing (grain absorption rate.) For "normal" size beers the difference is in the 8.5 - 9.0% range.

If we look at Case 2 vs. Case 3, there isn't a big difference between sparging and not squeezing vs, squeezing and not sparging (especially if we look at SG.) Squeezing harder will improve the efficiency of no sparge, and better draining without squeezing will increase the efficiency of the sparged case.

The case of squeezing and then sparging is always the highest efficiency option.

Now that you have a feel for the quantitative differences among the spage/squeeze options, you can decide for yourself on the effort vs. efficiency trade offs.

All that said, having a consistent process, that allows you to predict what a recipe will produce on your system, is more important to good brewing than a few percentage points of mash/lauter efficiency.

Brew on