augiedoggy

Well-Known Member

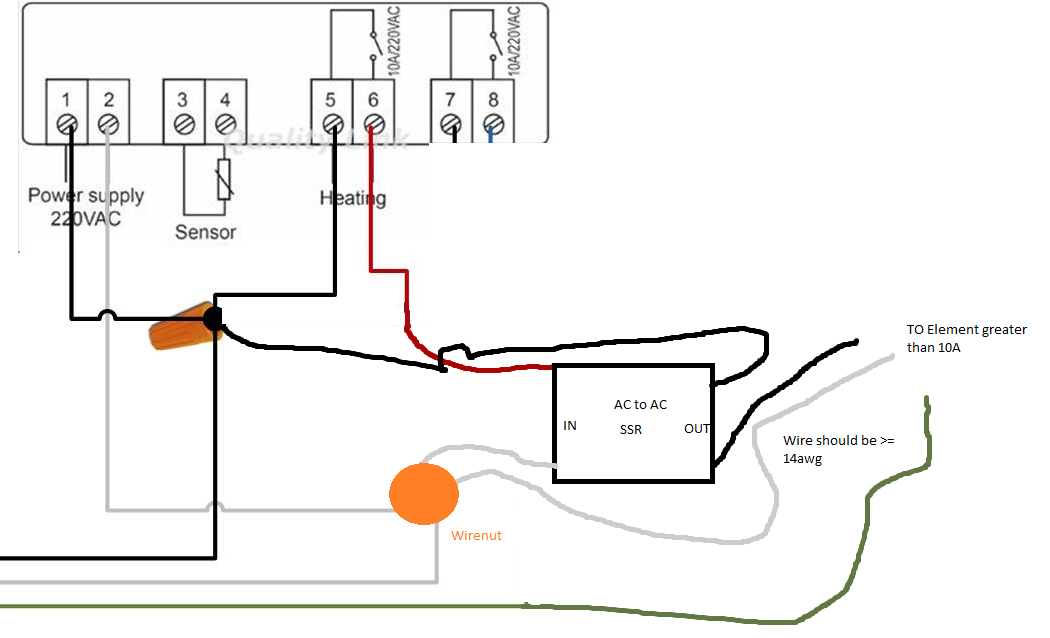

running on 120, that 240v is going to be a equivlient to a 250w element, also known as pointless. So defiantly the first 120 one over the other one.

Your not understanding at all, I was never talking about running any of these elements at any other voltage than what they are designed for,

the first link is a 120v rated element rated at 1000w output....

The second link is a 240v rated element also rated at 1000w output...

They are the same size and length... the are just wired differently internally to produce the same heat with different voltages. So someone limited to 120v would want to select the first choice and someone running 240v would choose the second.... in the earlier comments it was implied that an effective rims tube couldnt be made with 120v vs 220 and I was simply stating that it doesnt matter if you have 120v or 220... just select the appropriate element prior to building... the only reson people run the larger 220v elements at 120v is because they provide too much heat for a rims application and they provide very low watt density this way and the 120v standard hot water heater elements are generally too short with little surface area in contact for too short a time...... with small long cartridge heaters this is not an issue.

I run my 1000w element at the full 240v and can assure you there is NO scorching at all... The longer the element the lower the watt density, you can find these 1000w elements in lengths up to a few ft long.... this makes them actually a better choice than what most people are using...

just like comparing a longer herms coil to a short one.