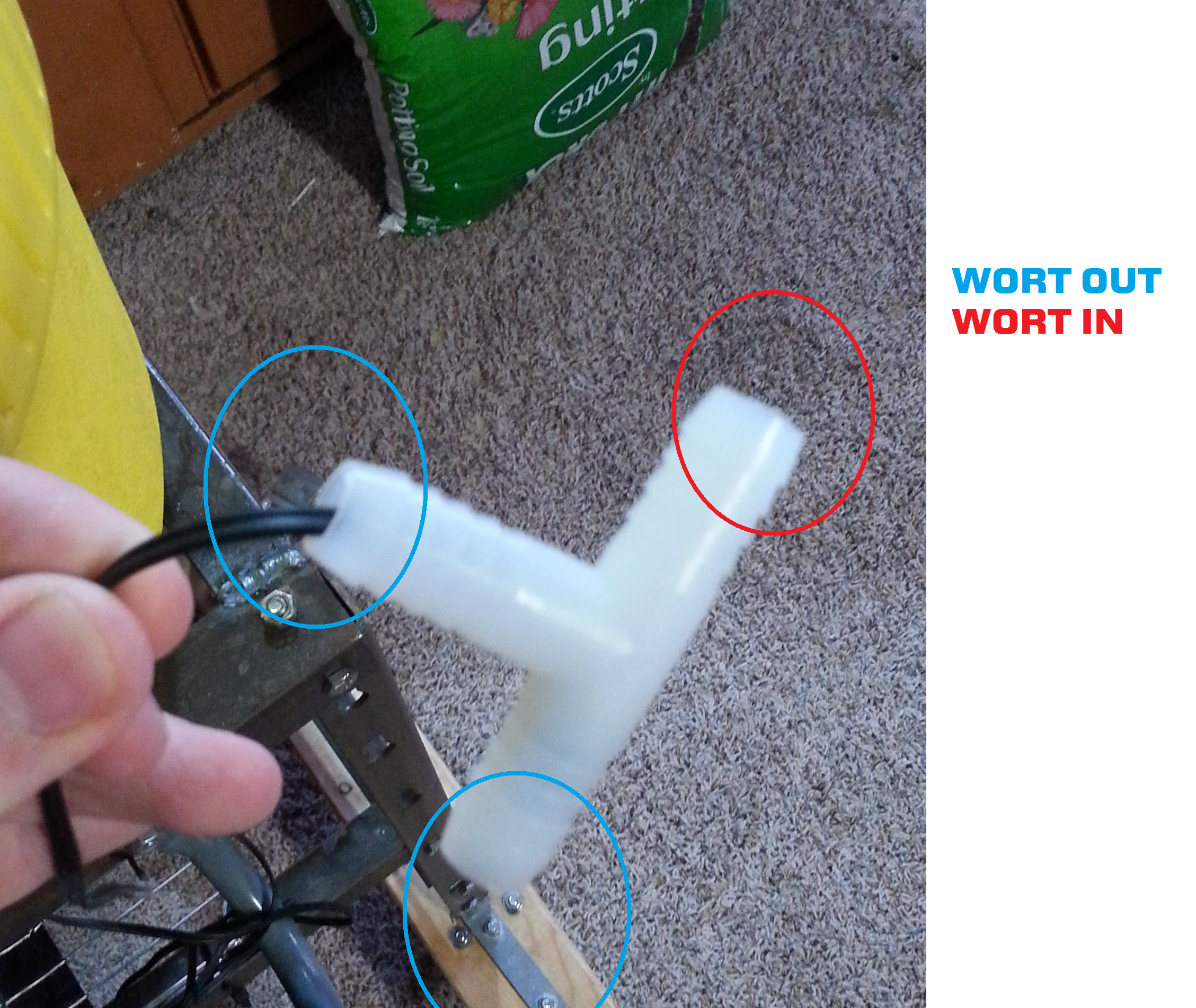

The liquid needs to flow over the probe so it can get a reading. its really not complicated at all, its so simple that it might look confusing. just thread the probe in one end of the tee then out the side. the probe end is long enough where it wont be able to do the 90 degree corner and slip through. then just shove the hose on either end, it doesn't matter and then toss the entire thing in the ton on top of the bed.

Got ya. My confusion was that I thought this nylon tee was outside of the mash tun. Now I understand

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)