DuncB

Well-Known Member

You run the cleaner through before every brew ? Or just when you first get it.

Instructions say to push it onto the vertical pipe about 1/2". In fact, there is a lip inside the rubber that defines that point."The rubber piece on the malt pipe shouldn't be pushed down all the way."

I can't find it now but I remember reading that the rubber piece should be adjusted according to the level of the liquid.... something like two inches above. The first time I used it I trusted that the trub filter would do its job so I put hops in loose. I wasn't happy with the results so I'm going back to my hop spider again. I agree with the need for a port on the lid for adding a steam slayer. I had already decided that is a mod I would do in the future. The one thing I really miss that my Anvil Foundry had was a delay start feature so I could fill the unit up the night before brewday and have it turn on to reach strike temp in the morning.

The knockout port doesn't even get warm. So, before sending the wort to the fermentor, there needs to be at least a few seconds of boiling wort recirculated back to the boiler before chilling begins.Doesn't heat convect from the pump to the knock-out? Even if those components aren't in direct contact with boiling wort, it seems like they would at least heat up to a Pasteurization temperature long enough to destroy most nasties.

Turn on the pump. Open the "knockout" valve on the front. Woosh! I brewed 4 batches on mine this weekend.I ordered one of these. How do you transfer wort to the fermentor?

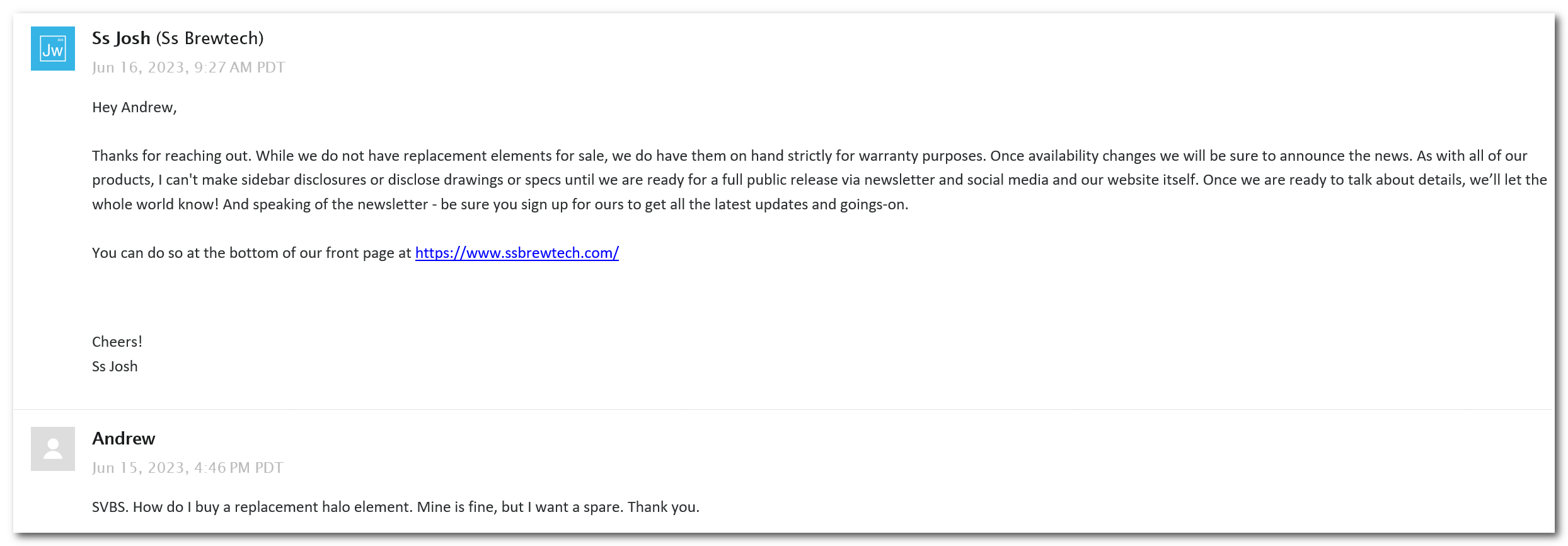

Thank you for this I was wondering about that, and since he mentioned warranty, what is the warranty on the SVBS? I didn’t see it on the website.In case anyone was wondering about replacement parts, such as halo element, here is the reply I got today from SSBT. They replied within a day, so that's good. Not crazy about the answer, but hopefully there is a plan to offer parts in the near future.

View attachment 822592

Yeah, I guess we can only drink so much beer. That was always a problem I had when I did bigger batches. One reason I'm looking at AIO's is the 5 gallon (and smaller) batch sizes. Did you ever get your efficiency numbers up? I remember you mentioning that they were lower than you expected. I'm not really sure what to expect in that department.I am a very happy user of the SVBS. I'm dying to brew again, but my pipeline is more than full right now.

No, efficiency is still 55-60%. I'll figure that out eventually. Even if I don't, I'm still happy with it.Yeah, I guess we can only drink so much beer. That was always a problem I had when I did bigger batches. One reason I'm looking at AIO's is the 5 gallon (and smaller) batch sizes. Did you ever get your efficiency numbers up? I remember you mentioning that they were lower than you expected. I'm not really sure what to expect in that department.

Don't know if you read through this thread, but my I've used my dishwasher twice and it cleaned the basket perfectly, even when it was used for 3 batches in a row haha.I still love mine. I’ve found to get my efficiency consistently in 65-70% range, I’ve had to crush really fine. Makes cleaning the basket kinda a pain but I have figured out a process for that.

I would definitely buy it if I had to do it all over again.

Don't know if you read through this thread, but my I've used my dishwasher twice and it cleaned the basket perfectly, even when it was used for 3 batches in a row haha.

One issue I noticed in some of the negative reviews was they talked about that hop screen getting blocked up. Obviously it would depend on amount of hops so quite style dependent but just wondering if anybody had any issue or if they were using a hop spider or something?I agree that the videos were fairly rushed and the negative aspects they picked out weren't really important to me either. One reviewer really seemed put out that the heating element was "overpowered". I have to say, you'll never hear me complain about anything having too much power. Too little maybe, lol. Plus, it seems odd that they only brewed on the unit one time, if at all. I would expect at least a couple of brews on it to determine issues?

As far as cleaning the basket goes, that doesn't bother me. I'd probably just hit it with a hose, then let it dry overnight and brush off the rest.

Coltr88, since you are crushing pretty fine, have you had any issues with a stuck mash? It seems like the design would somewhat prevent that from happening, but again, very little feed back.

That DID happen to me the first brew. Since then, I switched to a hop spider and it hasn't happened again. It was a smokebeer, with only 2.5 oz of hops, so I don't think loose hops in the boil is ever going to work.One issue I noticed in some of the negative reviews was they talked about that hop screen getting blocked up. Obviously it would depend on amount of hops so quite style dependent but just wondering if anybody had any issue or if they were using a hop spider or something?

Pump is fine. It’s no march pump though.The hops issue does seem to be a problem with almost all of the AIO's. I usually use a hop spider. Not a big deal, but it would be nice not to have to bother with one.

Another question I have is about the pump. I was leaning towards one of the units that have more modular parts, but I do like the way the svbs tucks it away. Assuming, of course, it is replaceable should a problem occur. It seems to be more than strong enough for the unit?

Thank You! excited to get this thing goingI'm using about 0.035" crush with my three roll mill. I would probably ask your LHBS for a double crush and go from there.

I am noticing that you added your grist @ the mash temperature. Do you or any of the other users have an initial strike temp that is higher than mash temperature? If so, what is a good ballpark differential between strike and mash? I know Palmer recommends 10 degrees but that seems high given the degree of mash control available w/ the svbs. I am planning 153 for my next brew with an expectation of 80% attenuation. Last brew I didn't fully understand how to control the mash so my temperature fell and my beer dropped like a rock with 90% attenuation (S-04).I exported the temperature data and annotated. I was in no hurry. Next brew I'll probably shorten the mash period. I'll also be attempting some sort of sparge.

View attachment 818481

I would not do any differential temperature, for the reason you mentioned. I posted a graph above somewhere, but you can see that the temperature rebounds to the desired mash temperature very quickly.I am noticing that you added your grist @ the mash temperature. Do you or any of the other users have an initial strike temp that is higher than mash temperature? If so, what is a good ballpark differential between strike and mash? I know Palmer recommends 10 degrees but that seems high given the degree of mash control available w/ the svbs. I am planning 153 for my next brew with an expectation of 80% attenuation. Last brew I didn't fully understand how to control the mash so my temperature fell and my beer dropped like a rock with 90% attenuation (S-04).

Thanks for the help.

I received the email today and am considering the purchase. Are folks here still happy with the SVBS experience?Anyone thinking about this AIO should have a look at the Black Friday sales sheet. Pretty good savings there. I bought the SVBS, the immersion chiller, and the casters for it. I would do it again, too!

https://www.ssbrewtech.com/pages/bfcm

You know how I feelI received the email today and am considering the purchase. Are folks here still happy with the SVBS experience?

I’d likely use an external chiller and a spike steam condenser, which I hear doesn’t fit great. I had been leaning towards the spike solo, but the SS BF deal is hard to pass on.You know how I feel

I would also use their hop spider, but I don't think it will fit into the kettle at the same time as the chiller, which is a problem with my process. However, if you're considering using an external chiller (e.g. plate chiller) then it looks like a good design.

Enter your email address to join: