Gnomebrewer

Well-Known Member

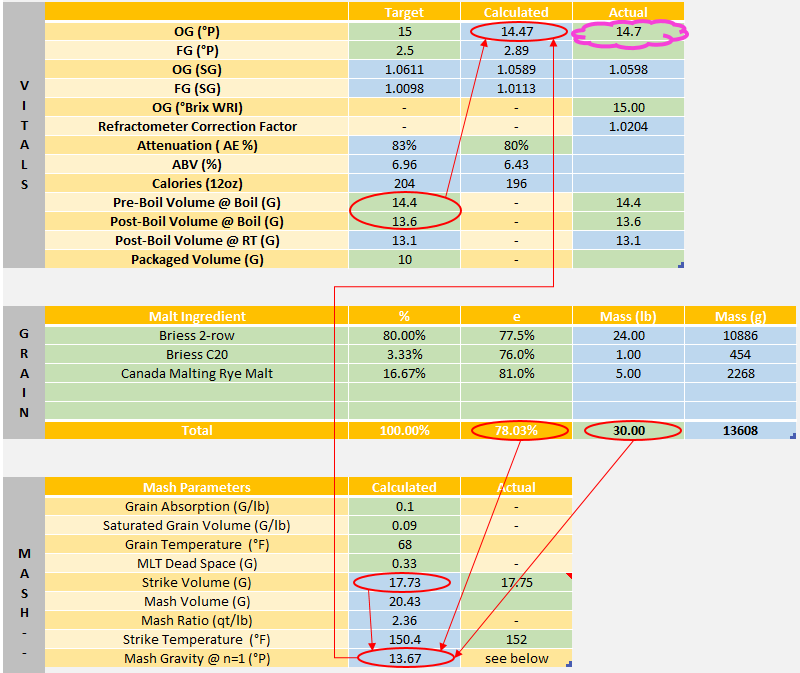

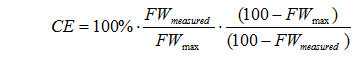

Pick one. Mash, Lauter or BH. I'm just LMAO wondering how people are calculating these values. I'm obviously using a whole different set of equations

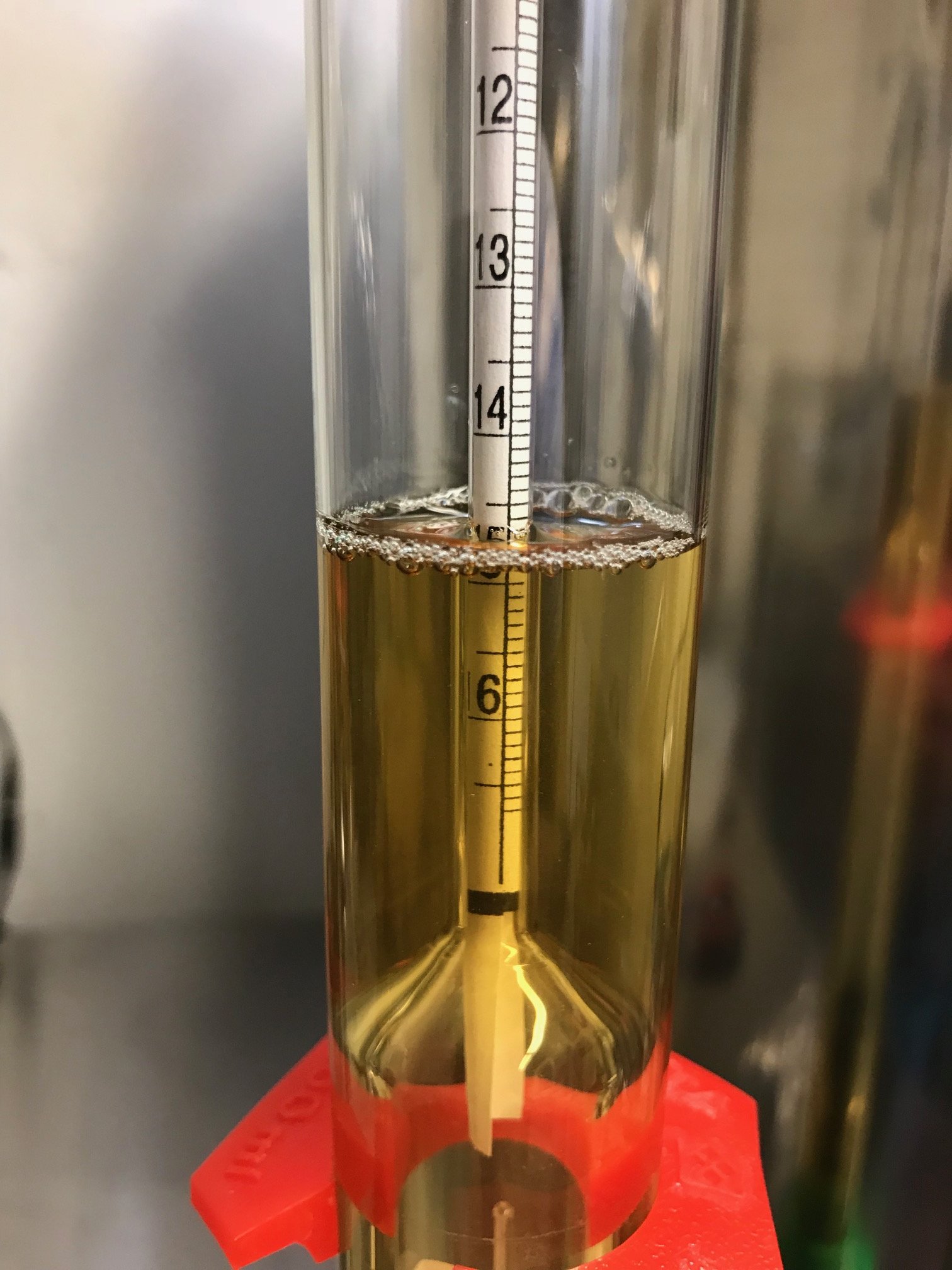

This thread's about mash efficiency. Lauter and BH efficiency have nothing to do with it. My post #26 details how I do my calculations - if I just want an estimate of the efficiency I use my quick method, if I want a more accurate measurement I work out based on ppg for each grain type. Most others seem to be using software. If you don't agree with my equations, let me know.

IME brewers who are getting unrealistically high BH efficiency are putting in more grain than they should be. Eg, I've brewed with a mate who always bragged about 90% BH efficiency, but was dumping about 10% trub (which, of course, would mean that the rest of his process was 100% efficient). It turned out he was rounding down measurements of grain (eg. 732g measured would be recorded as 700g). It's an easy way to boost efficiency! However, achieving MASH efficiency in the 90's isn't too hard if you can crush fine. It's processes downstream of that (especially the lauter) that are harder to do at high efficiency.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)