Is that an inline filter that you're using? Does that work well? Does it get clogged or impede the transfer?Rough chopped 10 ounces of espresso beans, drained the yeast cake and trub and added the beans to my coffee porter, then set the temp to 40, drained the trub and yeast cake on my black IPA and added 2 ounces of citra hops, washed and sanitized 50 bottles, then bottled an Irish Red..

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I did for beer today

- Thread starter iaefebs

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I'm working up a new recipe today. I've never been a big fan of amber/biscuit/victory, so I've decided that brown malt isn't just for porters. It's 5% Crisp brown malt, 2.5% Simpsons light C-malt, and the rest is Otter. It's a bit darker than I was expecting. Here's the wort being pumped into the kettle from my absurdly large grant.

And here’s how it turned out. It’s pretty big for me at a colossal 1.045. Ringwood should do good things with this wort.

And here’s how it turned out. It’s pretty big for me at a colossal 1.045. Ringwood should do good things with this wort.

Last edited:

Yes, it works well for keeping fine sediment out of my bottles..I've never had it clog to the point it was a problem, if I was using a siphon, I suspect it would be more problematic.Is that an inline filter that you're using? Does that work well? Does it get clogged or impede the transfer?

Purchased yesterday, and should start creating recipes very soon.

Finally got around to the comparison between Piraat and the Clone...

Still not happy with the carb level or the head retention, but the flavor is 95% similar -- the clone is just a bit hoppier in the finish, something I expect will moderate over time.

I'm also hoping I didn't under-prime the 12 oz bottles. I used one carb tab per bottle.

Irregardless, the flavor is definitely close, and the tiny tongue bubbles persist to the end of the glass. I'm just not getting any head

retention.

Still not happy with the carb level or the head retention, but the flavor is 95% similar -- the clone is just a bit hoppier in the finish, something I expect will moderate over time.

I'm also hoping I didn't under-prime the 12 oz bottles. I used one carb tab per bottle.

Irregardless, the flavor is definitely close, and the tiny tongue bubbles persist to the end of the glass. I'm just not getting any head

retention.

Brewsmith

Home brewing moogerfooger

Today I continued the kegerator rebuild. I put the last coat of paint on the fridge and then reassembled it. I had problems in the past with mildew on the outside of the door around the faucets from the lack of insulation inside. Today I started the remedy. I cut a scrap of wood to go against the inside of the fridge door with holes for the shanks. Some liquid nails and tightening the nuts made that secure. Then I put the CO2 manifold back inside and installed the faucets and homemade tap handles. Maple, Mahogany, Walnut, and (I think) Bubinga. I plugged the fridge in and set a couple kegs in to get cold. Tomorrow I finish the insulation in the door with some spray foam, and install new beer line. By the end of Sunday I might have a functioning kegerator again! Then the task of refilling it…

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

Today I dry hopped my Sierra Nevada Pale with 40g of Cascade.

Transferred kveik ipa to serving keg with dry hops

Cleaned out fermenting keg

Designing a tap label

Cleaned out fermenting keg

Designing a tap label

Brewsmith

Home brewing moogerfooger

My kegerator is finally functional. I got new beer line and connected everything together, ran some beer line cleaner through everything and checked for leaks. I’ve got two beers in there now, a two year old imperial stout and a Belgian dubbel from several years ago. Now the task of brewing regularly to keep this thing full.

Busy day at the brew house today. Watched the opening day ballgame in Tokyo with a beer and a hot dog at 6:14 am to prepare. Go beer! Happy to see either the Cubs or The Dodgers lose.

Cleaned (PBW, rinse, starsan) 2 spent kegs and packaged up six gallons of English brown ale in a torpedo keg. Carbing now. Ready soon enough.

Still have to clean out the cononical fermenter this afternoon, but first... An ice cold pilsner with lots of bubble. Ahhhh. Back to work soon.

Cleaned (PBW, rinse, starsan) 2 spent kegs and packaged up six gallons of English brown ale in a torpedo keg. Carbing now. Ready soon enough.

Still have to clean out the cononical fermenter this afternoon, but first... An ice cold pilsner with lots of bubble. Ahhhh. Back to work soon.

Made a yeast starter for brew day this Friday.

John

John

Kegged up my single hop Nectaron hazy. It was a bit of a pain as I managed to block my Bounce with hop matter about three times due to the filter in my Fermzilla being absolutely caked in it. Ended up blowing that out with some CO2 which sorted things out.

ClaudiusB

Well-Known Member

I ran into a pump problem today. My automated mash water delivery pump for the two mash tuns quit. The other pump in the same system used for the guided/manual brewing took over but it requires operator control.

The pump capacitor turned out to be defective.

The pump capacitor turned out to be defective.

Unfortunately, my automated mash water delivery system only works when my wife hears me and agrees to deliver the mash water.I ran into a pump problem today. My automated mash water delivery pump for the two mash tuns quit. The other pump in the same system used for the guided/manual brewing took over but it requires operator control.

The pump capacitor turned out to be defective.View attachment 871378

Kegged my dunkleweizen

Ugh, capacitors.I ran into a pump problem today. My automated mash water delivery pump for the two mash tuns quit. The other pump in the same system used for the guided/manual brewing took over but it requires operator control.

The pump capacitor turned out to be defective.View attachment 871378

I miss the olden days of yore when they were overbuilt and could be trusted.

I made an early escape from the grasping claws of my corporate overlords, so today was a busy day my hoopty brewery. I washed three kegs, boiled some small components in a heavy PBW solution, sanitized a 6gal keg, purged it, loaded it with finings and ascorbic acid then racked some fizzy yellow swill into the keg. It's the first batch of Panther Piss that I've brewed in over a year so it was nice to say hellow again to an old friend.

Kegged the Brut IPA. Stupidly plugged the scale into a switched outlet and switched it off mid-transfer, so I overfilled the keg a bit. No biggie.

What's a little more beer on the floor, right?Kegged the Brut IPA. Stupidly plugged the scale into a switched outlet and switched it off mid-transfer, so I overfilled the keg a bit. No biggie.

For what it's worth, I've switched to using a hose attached to the gas out that then goes into an old 2lt Erlenmeyer flask. I really like this new setup because I can go about my business and listen to the bubbles. When I stop hearing gurgling bubbles, I know it's time to shut off the valve on the fermenter and the 2lt flask gives my idiot brain plenty of time to react. No beer on the floor since I've adopted this technique.

Today I bottled my Sierra Nevada, 22 50cl bottles.

Cooled and popped test bottle #3 of Black Pearl's Revenge. I've already verified the taste; now the esthetics are coming into focus:

No beer on the floor. Closed loop, so the beer tried to go back into the fermenter but only made it halfway up the gas jumper line. Failed perpetual motion machine.What's a little more beer on the floor, right?

Oh.... I don't miss that. I adore that method because of its elegance, but I finally gave up and started doing pressure transfers. Damnit, I wish it was reliable, it's a beautiful way to transfer beer!No beer on the floor. Closed loop, so the beer tried to go back into the fermenter but only made it halfway up the gas jumper line. Failed perpetual motion machine.

Well, started my day by making my wife breakfast and taking her for her nail appointment ( recent back surgery prevents her from driving,but having pretty nails does wonders for her attitude) How is this related to beer you ask- HA, I'm botteling 2 - 5 gallon brews tomorrow, a coffee porter and a Cascadian black IPA, she is my capper...without her its a slow process, even with her in a chair she is a machine and runs a mean bench capper- and her labeling is better than mine, she can do both faster than I can fill. After her appointment,

I dragged her to the local home brew store to pick up a few things so I can brew Sunday,( and beyond)..I spent the balance of the afternoon washing and sanitizing bottles and gear for tomorrow, while I was doing that I ran 6.5 gallons of water through the RO/DI system for my Sunday brew... other than that- I did nuttin!

I dragged her to the local home brew store to pick up a few things so I can brew Sunday,( and beyond)..I spent the balance of the afternoon washing and sanitizing bottles and gear for tomorrow, while I was doing that I ran 6.5 gallons of water through the RO/DI system for my Sunday brew... other than that- I did nuttin!

Kegged a schwarz beer and an Australian golden ale. Cleaned three kegs from a festival an few weeks ago.

Didn't clean the fermenters, hoping to get a couple of brews done this week to dumped on top of those yeast cakes. The schwarz was Novalager, the ale was nottingham. Open to suggestion. Was thinking maybe a dunkle for the Novalager, since it was a dark beer. The Australian was hoppy, but not dry hopped, so maybe a pale ale. Haven't done a Baltic Porter in a season or two, but not quite into the big beers much anymore. Doing another festival in a three weeks, could brew something on the ale yeast for that or just shoot for replenishing for after that, probably the smarter idea.

Didn't clean the fermenters, hoping to get a couple of brews done this week to dumped on top of those yeast cakes. The schwarz was Novalager, the ale was nottingham. Open to suggestion. Was thinking maybe a dunkle for the Novalager, since it was a dark beer. The Australian was hoppy, but not dry hopped, so maybe a pale ale. Haven't done a Baltic Porter in a season or two, but not quite into the big beers much anymore. Doing another festival in a three weeks, could brew something on the ale yeast for that or just shoot for replenishing for after that, probably the smarter idea.

After the chiller-with-mold-in-it debacle, brewed up another batch of PF Lager this morning that is currently no-chilling. Boiled the hell out of the chiller yesterday but still has gunk; so right now heating up more water with some LA's Totally Awesome yellow cleaner stuff to recirculate through it after a 2-hour soak in said cleaner solution (tossed that, more gunk came out). Plate chillers have come way down in price on amazon, so if this doesn't work will just say the hell with it and get a new one.

Also found some new snaggy holes in my trusty Wilser bag after pulling it up from the mash; I've had this one for almost 4 years now and it's done well, but have had to make some repairs in it. New holes are not reparable (too small and stitching will put too much stress on it), so had to find a replacement. Found out, like many probably already have, that Mike is now selling his bags on brewhardware.com! New one ordered, will be here next week with Bobby's excellent customer service.

Also found some new snaggy holes in my trusty Wilser bag after pulling it up from the mash; I've had this one for almost 4 years now and it's done well, but have had to make some repairs in it. New holes are not reparable (too small and stitching will put too much stress on it), so had to find a replacement. Found out, like many probably already have, that Mike is now selling his bags on brewhardware.com! New one ordered, will be here next week with Bobby's excellent customer service.

Bottled the remains from 4 kegs and distributed bottles to my tasters…. Only beer left in kegerator is the NA pale ale. Fortunately there’s 3 full kegs in storage Frig. Time to “Brew Up”. I’ve got grain for Irish Red then it’s an IPA and a bitters for the caskerator..

I'm making a hefeweizen

Stewarding at NHC in NYC.

Last edited:

Made 5 gallons and probably drank 2

Kegging my first "cold IPA" today...

Cheers!

Cheers!

Then whizzed out 3?Made 5 gallons and probably drank 2

Richardbemboka

Member

- Joined

- May 29, 2019

- Messages

- 5

- Reaction score

- 21

A 50l batch of Marzen in the fermenter

Today I brewed 19 L of Kolsch

3500g Crisp German Pilsner malt

400g Vienna malt

100g Torrefied wheat

23g Styrian Golding at 60m

14g Mittelfruh at 60m

26g Hersbrucker at 15m

28g Saaz at 80C for 15m

Dry Kolsch yeast at 16C

OG 1.052 giving a BHE of 78%

3500g Crisp German Pilsner malt

400g Vienna malt

100g Torrefied wheat

23g Styrian Golding at 60m

14g Mittelfruh at 60m

26g Hersbrucker at 15m

28g Saaz at 80C for 15m

Dry Kolsch yeast at 16C

OG 1.052 giving a BHE of 78%

Made Yooper's Oatmeal Stout, subbed Baird's Roast Barley 600L, and I'm going to use S-04, but other than that, no changes. It's boiling now!

One other difference: OG 1.056, and volume more like 2.9 gallons instead of 3.0 gallons

One other difference: OG 1.056, and volume more like 2.9 gallons instead of 3.0 gallons

Last edited:

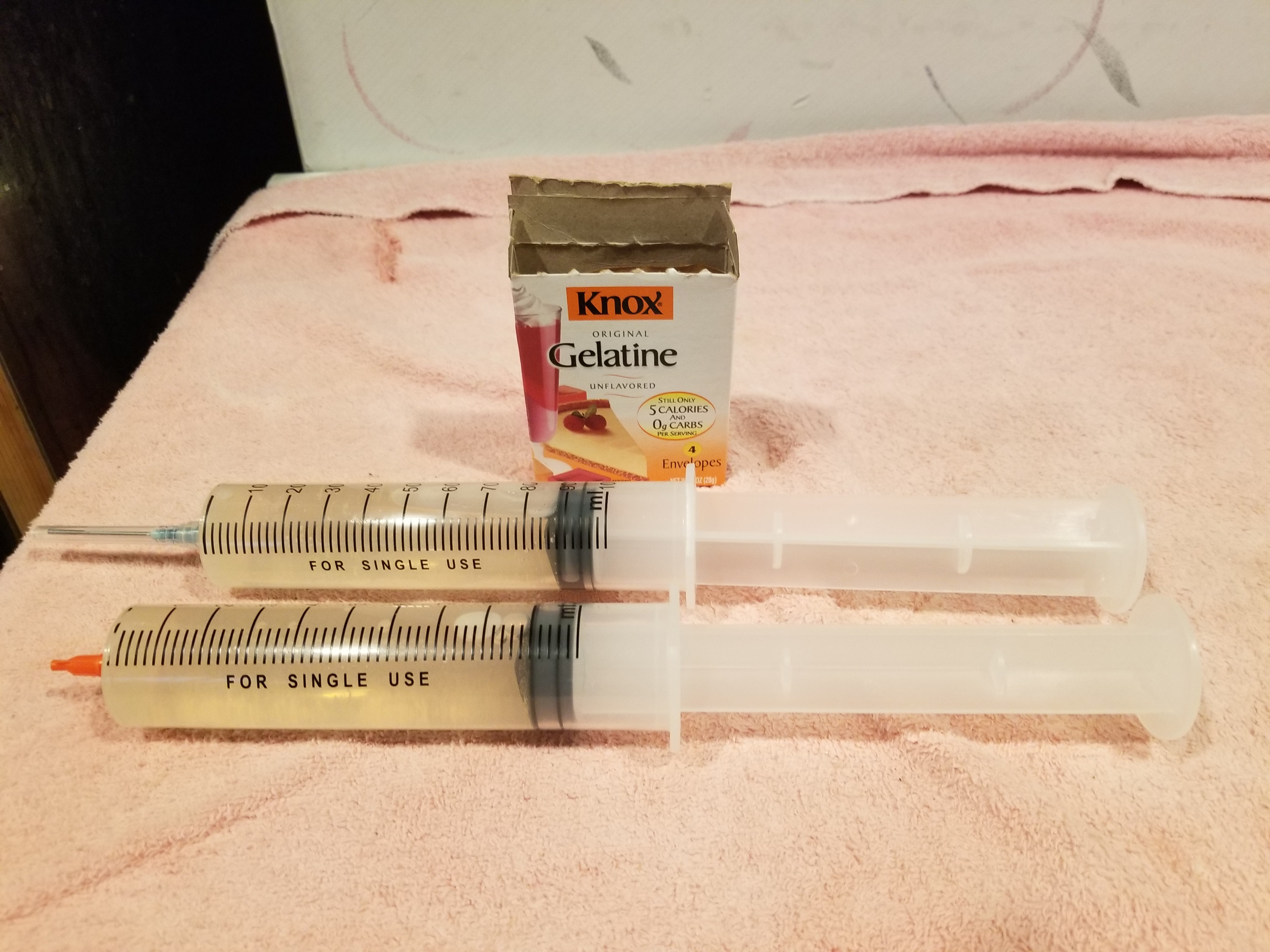

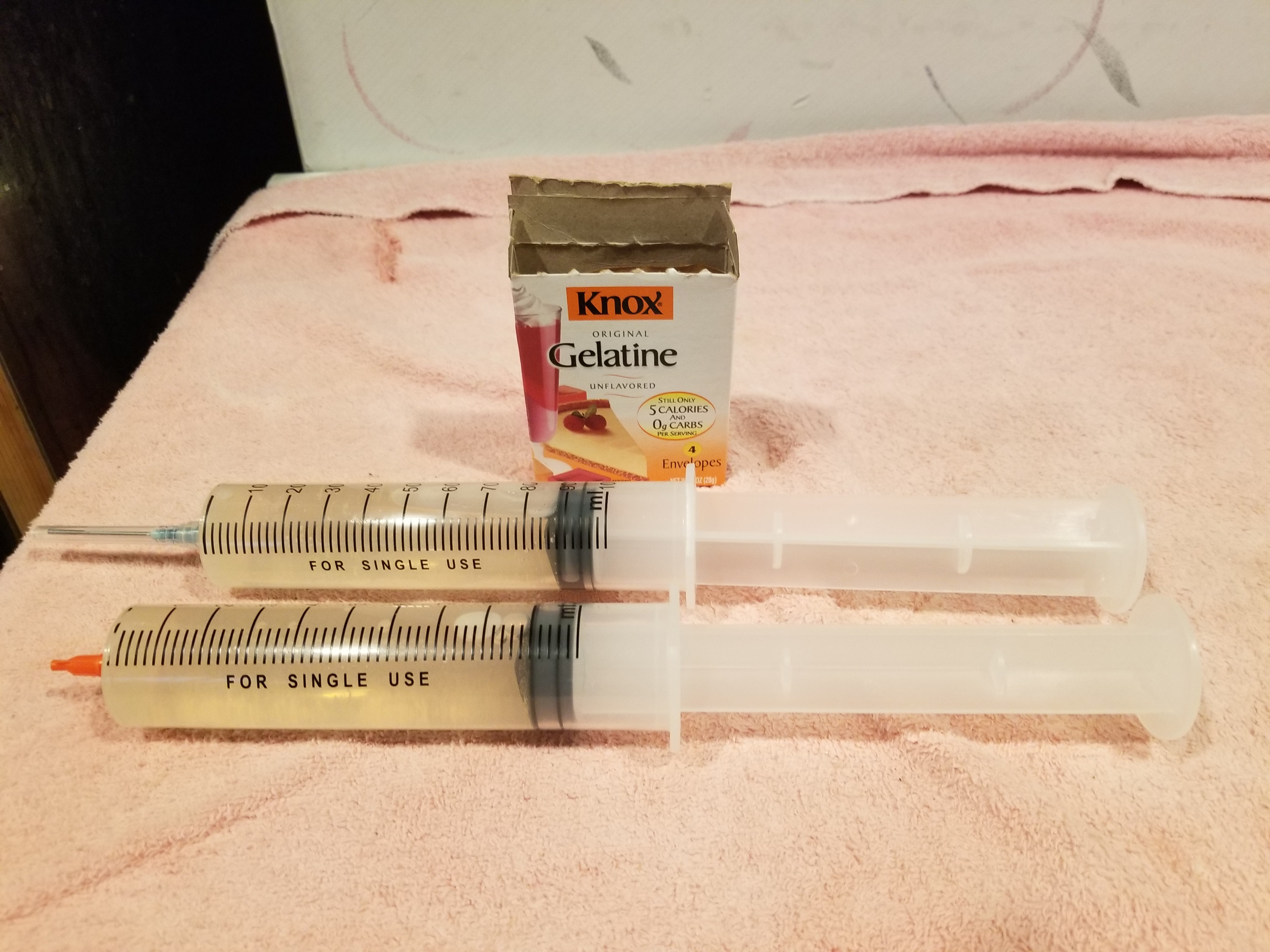

Never done this before but today I hit my first "cold IPA" brew with the gelatin treatment before putting it on gas. Loaded a pair of 100ml syringes with a split packet of Knox bloomed in 200ml of boiled then chilled water, warmed back up to 150°F and injected into very cold kegs as prescribed.

Went well, very curious to see how this turns out...

Cheers!

Went well, very curious to see how this turns out...

Cheers!

Opened and drank the first 12 oz production bottle of Black Pearl's Revenge. Very tasty, carbed, but not much head retention.

It's akeeper drinker.

It's a

Similar threads

- Replies

- 66

- Views

- 2K

- Replies

- 20

- Views

- 1K

- Replies

- 55

- Views

- 2K

Latest posts

-

-

-

-

-

-

-

Barleywine natural conditioning failed, switched to force carb, but now what? 😆

- Latest: BrewnWKopperKat