I agitated and inverted the Black Pearl's Revenge to ensure the carbonation drops had completely dissolved. 48 12oz and 3 16oz bottles, all resting peacefully in protected, room-temperature habitats, dreaming of drunk brewers and dark sewers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I did for beer today

- Thread starter iaefebs

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

BrewMan13

Whole Nother Level Brewing

I just finished my first crack at this style. Having no idea what it was supposed to taste, I just followed a recipe I found online. I enjoyed it well enough, most in my brewclub thought it was too smoky, and the judges at the competition I entered it in said it had virtually no smoke lol.I bottled 5 gallons of Skibsol, a Danish "ship's beer." The hydrometer sample had a nice, smoky aroma and flavor from the Weyermann Rauchmalz. Filled 51 12oz longnecks. About 4.6% ABV.

I just finished my first crack at this style. Having no idea what it was supposed to taste, I just followed a recipe I found online. I enjoyed it well enough, most in my brewclub thought it was too smoky, and the judges at the competition I entered it in said it had virtually no smoke lol.

The few recipes I found online were, at best, a guess as to the authentic style. I just went along with one of them, made a few minor tweaks, and shot for a session smoke beer.

I've encountered variances in smokiness from beers I've brewed. This latest had 73% Weyermann beech-smoked malt, but the sample I tasted was not in-your-face smoky. I still like it so far, will see how it turns out after conditioning.

BrewMan13

Whole Nother Level Brewing

Yeah, I have a high threshhold for smoke and mine wasn't overpowering to me; I used beechwood and cherrywood smoked malts in it. Basically followed this: https://beerandbrewing.com/recipe-right-proper-skibsol/The few recipes I found online were, at best, a guess as to the authentic style. I just went along with one of them, made a few minor tweaks, and shot for a session smoke beer.

I've encountered variances in smokiness from beers I've brewed. This latest had 73% Weyermann beech-smoked malt, but the sample I tasted was not in-your-face smoky. I still like it so far, will see how it turns out after conditioning.

Yeah, I have a high threshhold for smoke and mine wasn't overpowering to me; I used beechwood and cherrywood smoked malts in it. Basically followed this: https://beerandbrewing.com/recipe-right-proper-skibsol/

I remember seeing that one. Their "trad" version uses close to 100% smoke malt. Mine was kind of in between the two for smoke. 73% smoke malt, 10% Munich I, 8% rye, 6% Carapils, 3% Carafa III.

Kegged my Irish Red today!

John

John

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

Brewsmith

Home brewing moogerfooger

Continuing my moving in and unpacking all of my stuff, today I got to organizing some of the beer things. My garage was built in 1950 and my grandparents lived here since ‘51. My grandfather built these shelves that are not adjustable and are kinda impractical for most things. He kept paint cans, thinner and chemicals on them. They are now my growler and beer glasses storage.

I’ve collected dozens of growlers over the years and unfortunately, several of them are from breweries that no longer exist. Most of them date to my beer explorations in the mid 2000’s. I live in Los Angeles, and it was a beer wasteland back then. I had to travel to San Diego, the SF Bay Area, and up the West Coast to get good beer. I have one from just about every local brewery, and many from the surrounding area including several beer destination spots in the 2000s-2010s.

Lots of glasses that I’ve collected from just about everywhere, including the original HBT glasses from 2008.

And as a bonus, some brewing awards from 2008 and 2009. Between 2007 and 2009 I was heavy into competition brewing and racked up a few awards. The ones pictured are just from the LA County Fair in 2008 and 2009. My wife framed them many years ago. The recipe that took the 2nd best of show is here.

I’ve collected dozens of growlers over the years and unfortunately, several of them are from breweries that no longer exist. Most of them date to my beer explorations in the mid 2000’s. I live in Los Angeles, and it was a beer wasteland back then. I had to travel to San Diego, the SF Bay Area, and up the West Coast to get good beer. I have one from just about every local brewery, and many from the surrounding area including several beer destination spots in the 2000s-2010s.

Lots of glasses that I’ve collected from just about everywhere, including the original HBT glasses from 2008.

And as a bonus, some brewing awards from 2008 and 2009. Between 2007 and 2009 I was heavy into competition brewing and racked up a few awards. The ones pictured are just from the LA County Fair in 2008 and 2009. My wife framed them many years ago. The recipe that took the 2nd best of show is here.

Attachments

Last edited:

Off and running on my first "cold IPA" brew. Underlet the strike at 9 and the wort is already running clear...

Onwards!

[edit] Recirculation...

...and the boil...

...and finally whirlpooling.

Bit of an adventure: my last 1/2 pound of rice hulls was pretty close to sawdust and wreaked havoc with my FB. Ploughed through with a back-flush and a couple of stop-and-stir deals. Still managed to hit the design OG so it's gonna be OK...

Pitched rehydrated 34/70, gassed up with straight O2,and parked in Chamber 2. By the time I was done cleaning up it was already burping...

Cheers!

Onwards!

[edit] Recirculation...

...and the boil...

...and finally whirlpooling.

Bit of an adventure: my last 1/2 pound of rice hulls was pretty close to sawdust and wreaked havoc with my FB. Ploughed through with a back-flush and a couple of stop-and-stir deals. Still managed to hit the design OG so it's gonna be OK...

Pitched rehydrated 34/70, gassed up with straight O2,and parked in Chamber 2. By the time I was done cleaning up it was already burping...

Cheers!

Last edited:

I love a strong fermentation with like minimal lag time.

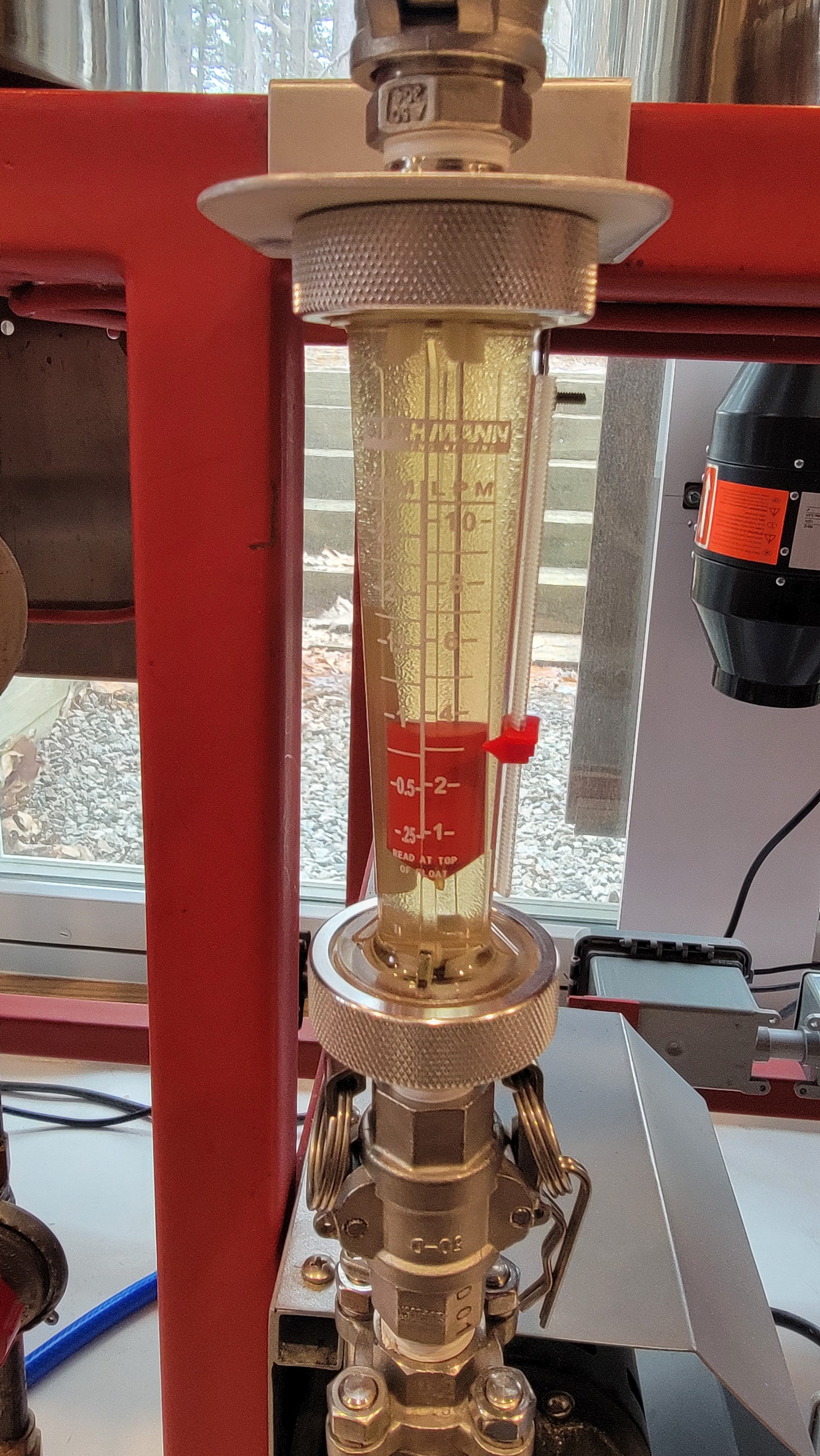

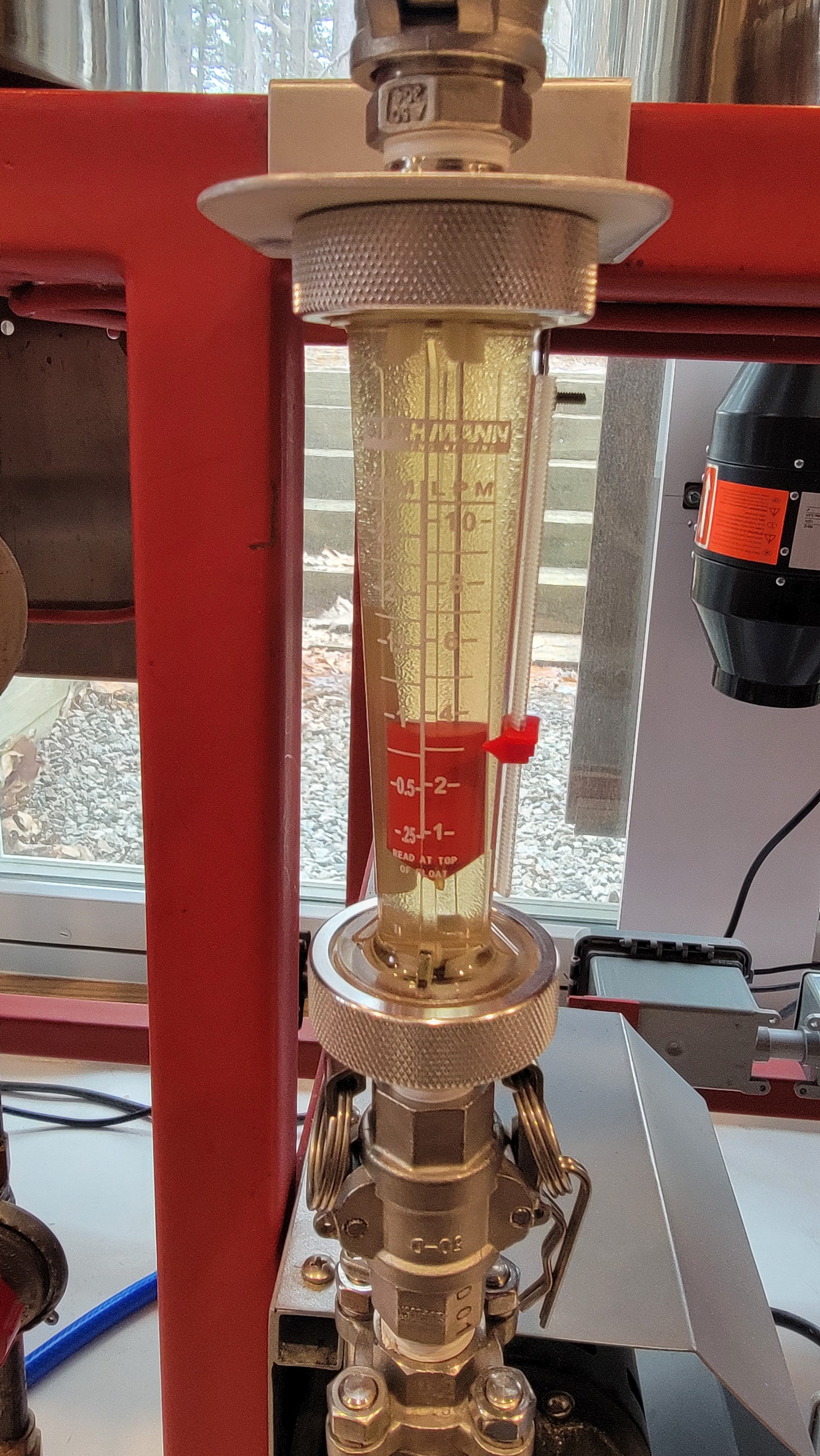

This is yesterday's "cold IPA" brew rocking along this morning.

34/70 seems quite happy running at 65°F instead of those chilly lager temperatures

Cheers!

This is yesterday's "cold IPA" brew rocking along this morning.

34/70 seems quite happy running at 65°F instead of those chilly lager temperatures

Cheers!

Mashing in on a 6.2% single hop DDH hazy using 1/3kg of 2024 harvest Nectaron. Out of my usual Golden Naked Oats so shifted up the gain bill a bit with some torrified wheat and CaraHell.

Massively overshot my OG though. 1.064 target, 1.078 achieved (!!!).

Massively overshot my OG though. 1.064 target, 1.078 achieved (!!!).

Last edited:

Started setting up my garage brewery again for a Saturday double header!!

I cleaned another Sanke keg and transferred a Czech Pilsner into it then placed it in the kegerator to lager for about 6 weeks. Then I enjoyed, I mean tested a new pale ale brewed 3 weeks ago and simply enjoyed a couple of IPAs brewed back in January.

Ordered another 19L corny.

Since I converted one to be a solera keg for bretted beer I've been forced to keg up only once I've kicked one and that's resulted in some...overindulgence to get kegs clear, especially with my hoppier beers where I very much don't want them sitting on the green matter.

Also recharred and vacuum sealed my smaller oak staves up in about a third of a bottle of Bulleit bourbon.

Since I converted one to be a solera keg for bretted beer I've been forced to keg up only once I've kicked one and that's resulted in some...overindulgence to get kegs clear, especially with my hoppier beers where I very much don't want them sitting on the green matter.

Also recharred and vacuum sealed my smaller oak staves up in about a third of a bottle of Bulleit bourbon.

Packaged up two corny kegs with a traditional Irish Stout. Tastes wonderful and the FG came in as expected, for a nice 4.1% ABV. Purged and put on about 10psi of CO2 before storage in the music studio closet for several months. That should be just about perfect to speed up serving when the time comes.

Then... The fun part. Cleaned the 2 NB buckets the stout fermented in and was thrilled to have another PBW jar on hand since the old one just kicked.

Finally ... I need to clean corny keg #2, which is my English Ale tap. I regret I am without a nice English Ale for a few weeks due to going hog wild on making Czech pilsner batches. (Now at about 15 gallons of backlog lager). Busy day for not brewing up something new.

Then... The fun part. Cleaned the 2 NB buckets the stout fermented in and was thrilled to have another PBW jar on hand since the old one just kicked.

Finally ... I need to clean corny keg #2, which is my English Ale tap. I regret I am without a nice English Ale for a few weeks due to going hog wild on making Czech pilsner batches. (Now at about 15 gallons of backlog lager). Busy day for not brewing up something new.

flipster

utility beer research kitchen

Somehow there was always some brew more urgent than this, then the fridge was full-full (a lot of cider had to be made in autumn 2024) and finally it was time to use the Galaxy hops.

But other than planned last year, I switched from lager to ale - still not enough room in the fridges for the fermenter.

I aimed quite a bit lower, OG-wise but today was an efficient day (you know, I can't deny I'm German... )

)

I finished my day with 31l 10,2°P in the fermenter plus 2,5l for the yeast (diluted it also a bit). It was a good day.

Last step: cleaning .... aaaaaand fooling around while flushing the hop-filter (and flooding the kitchen...)

But other than planned last year, I switched from lager to ale - still not enough room in the fridges for the fermenter.

I aimed quite a bit lower, OG-wise but today was an efficient day (you know, I can't deny I'm German...

I also could take 1,5l wort aside to boil down and use it later for yeast propagation - and still got over the expected OG.Galaxy Ale

OG 1,041, 24 IBU

grist: 2,7kg Pale Ale, 0,4g CaraAmber, 0,4g Acid, 1,5kg flaked corn

water: 17l mashing, 17l sparging, 6l spring water for chilling and diluting

10 min @ 57°C (134F) => 45 min @ 62°C (143F) => 30 min @ 72° (162F) => lautering at 78°C (172F)

boil: 80min

16g Galaxy hops - t-80';

44g Galaxy hops dry hopping t+5d:

yeast: MJ M44 WestCoast, harvested from a previous batch (this one was hangry!!)

I finished my day with 31l 10,2°P in the fermenter plus 2,5l for the yeast (diluted it also a bit). It was a good day.

Last step: cleaning .... aaaaaand fooling around while flushing the hop-filter (and flooding the kitchen...)

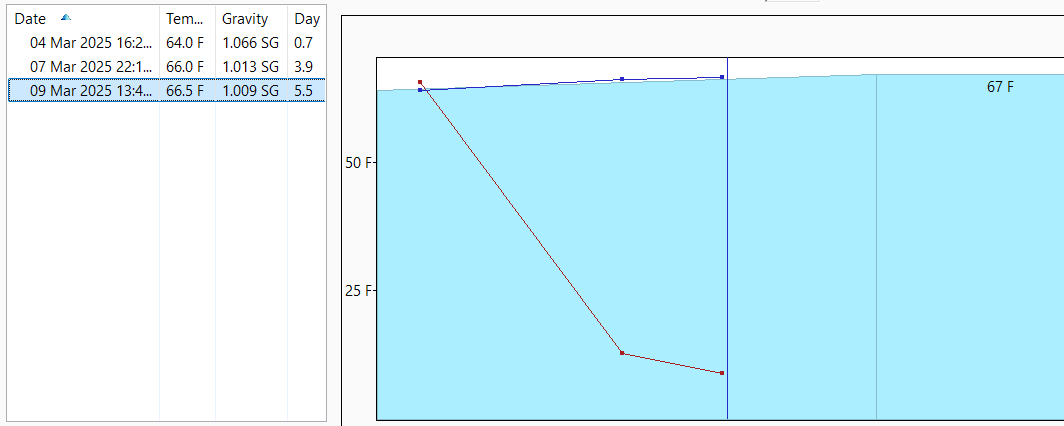

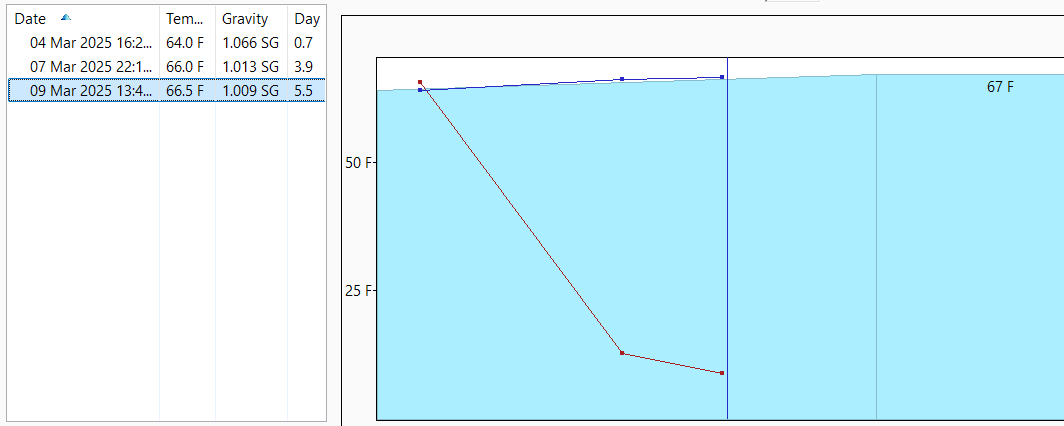

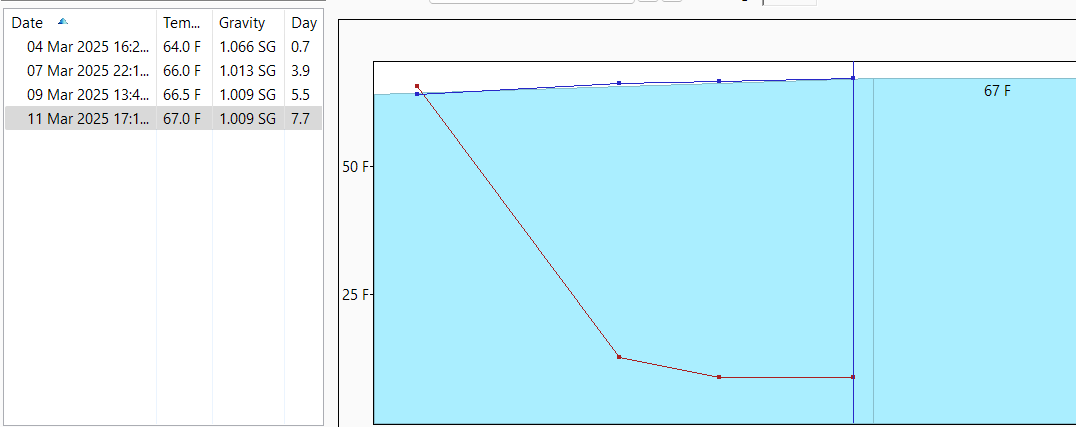

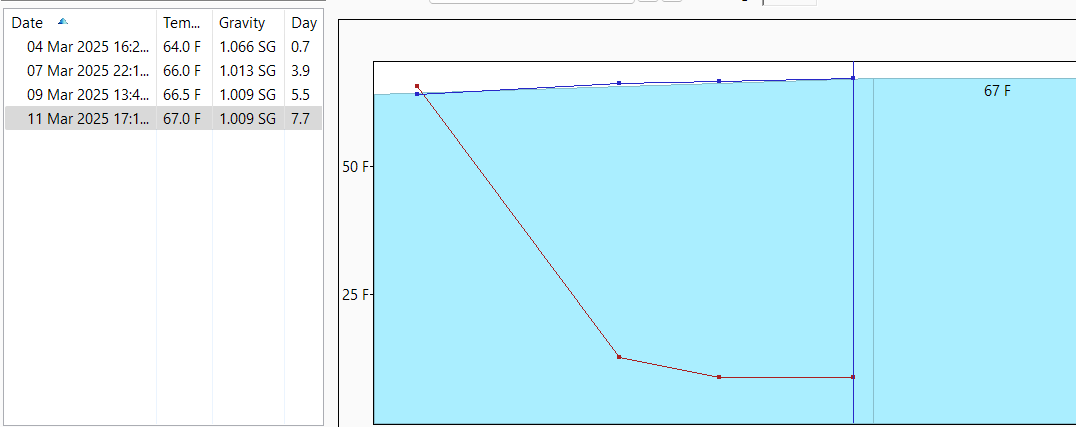

Checking the SG on my first "cold IPA" 34/70 fermentation which raged through the first 5 days and the curve has yet to flatten. Think I might want to go a bit less aggressive with the mash temperature profile next time as the current trajectory seems headed towards a "Cold Brut IPA"

Cheers!

Cheers!

Brewsmith

Home brewing moogerfooger

Brewsmith

Home brewing moogerfooger

Bought 25’ of silicone tubing to replace the cracking tubes on my recirculating rig and a free other things. I’m lucky one didn’t give way yesterday!!

ClaudiusB

Well-Known Member

I installed a replacement cap for the optical DO probe. It needs to be replaced every two years. Each cap is supplied with a unique calibration code on an SD card.

Compared to my amperometric DO sensor, no other consumables or calibration are required.

Compared to my amperometric DO sensor, no other consumables or calibration are required.

Bottled my Cascade/Citra IPA (tasted great!), and used it's yeast cake for this morning's brew, 3 gallons of Imperial Stout, this time I added some pale chocolate and chocolate rye to the mix, to really add some chocolatey oomph. I think it'll be great, based on tasting the wort before the hops went in.

edit: after the hops boiled for an hour, the wort tasted like "well, this is gonna take 9 months before it's drinkable"

edit: after the hops boiled for an hour, the wort tasted like "well, this is gonna take 9 months before it's drinkable"

Last edited:

Brewsmith

Home brewing moogerfooger

Continuing the kegerator rebuild.

Today was the CO2 manifold. The last time it was fully apart was when I built it in 2006. I took it apart the other day with the rest of the draft equipment, but this needed more attention. Inside it was a little gross, and some of the brass needed more work than just the regular cleaner. The brass parts got a bath in vinegar for a couple minutes and the green corrosion was gone. A little bit of teflon tape and it’s back together and ready to go through the wall of the fridge.

Today was the CO2 manifold. The last time it was fully apart was when I built it in 2006. I took it apart the other day with the rest of the draft equipment, but this needed more attention. Inside it was a little gross, and some of the brass needed more work than just the regular cleaner. The brass parts got a bath in vinegar for a couple minutes and the green corrosion was gone. A little bit of teflon tape and it’s back together and ready to go through the wall of the fridge.

Attachments

Took another gravity check of my "Cold IPA" effort and it looks like it avoided going "brut" on me

So, with the two days of flatline, I'm going to move along and set up for a two day soft crash prior to dry hopping...

Cheers!

So, with the two days of flatline, I'm going to move along and set up for a two day soft crash prior to dry hopping...

Cheers!

Gee, I can't top a fancy graph.Took another gravity check of my "Cold IPA" effort and it looks like it avoided going "brut" on me

So, with the two days of flatline, I'm going to move along and set up for a two day soft crash prior to dry hopping...

View attachment 870653

Cheers!

I cleaned my brew kettle and mashtun after yesterday's brew.

Kicked my own butt today - wanted some power to the beer shed so I could just mill out there. And add a light. And now my better half wants an outdoor motion sensor light.

So dug about 50' of a 24" deep trench, dug by hand. Fashion the proper 45° and 90° bends with 3/4 Cantex pipe. Fish a 12/2 wire thru (direct burial approved) the Cantex, cement all connections, ... Runs from the shed to the junction box on the house. All buried and mulched. Looks great. Invisible.

Exhausted. My trench digging days are behind me. Tomorrow? Uh oh.

So dug about 50' of a 24" deep trench, dug by hand. Fashion the proper 45° and 90° bends with 3/4 Cantex pipe. Fish a 12/2 wire thru (direct burial approved) the Cantex, cement all connections, ... Runs from the shed to the junction box on the house. All buried and mulched. Looks great. Invisible.

Exhausted. My trench digging days are behind me. Tomorrow? Uh oh.

Nothing like a good days work! Ya got my respect, a fifty foot trench by hand. I'm pooped just thinking of it!Kicked my own butt today - wanted some power to the beer shed so I could just mill out there. And add a light. And now my better half wants an outdoor motion sensor light.

So dug about 50' of a 24" deep trench, dug by hand. Fashion the proper 45° and 90° bends with 3/4 Cantex pipe. Fish a 12/2 wire thru (direct burial approved) the Cantex, cement all connections, ... Runs from the shed to the junction box on the house. All buried and mulched. Looks great. Invisible.

Exhausted. My trench digging days are behind me. Tomorrow? Uh oh.

You can't rent a ditch witch in Charlotte?dug about 50' of a 24" deep trench, dug by hand

I wanted to try out the Trench Mench.You can't rent a ditch witch in Charlotte?

I feel your pain. Several years ago I built a 10 x 20 shed for a woodshop. Hand trenched a run of 3 conductor 1/0 aluminum through pvc to feed a subpanel in the shed. Went 24" down for 40 feet. Just used a square spade. Elec inspector chuckled and said "you like to do things the hard way." Don't care, he signed off on it.

Thought I was gonna die myselfNothing like a good days work! Ya got my respect, a fifty foot trench by hand. I'm pooped just thinking of it!

Half way through I would be laying in the trench.Thought I was gonna die myself

Keep digging them trenches for when Putin invades the USA.

ClaudiusB

Well-Known Member

Remember our IPAs and Stouts suck he is coming for yours.Keep digging them trenches for when Putin invades the USA.

I suppose you are actually supposed to get those things permitted and inspected. It's easier if you don't.Elec inspector chuckled and said "you like to do things the hard way." Don't care, he signed off on it.

Today I brewed 15 litres of Sierra Nevada Pale on my Burco boiler and grain basket.

3000g Maris Otter

150g Medium Crystal

Cascade hops

30g 45m

30g 15m

40g to follow as a Dry Hop

US05 yeast

OG 1052 BHE 79%.

I never get a BHE much over 75% on my All in One.

Expecting ABV of 5.6%

3000g Maris Otter

150g Medium Crystal

Cascade hops

30g 45m

30g 15m

40g to follow as a Dry Hop

US05 yeast

OG 1052 BHE 79%.

I never get a BHE much over 75% on my All in One.

Expecting ABV of 5.6%

Popped test bottle #2 into the 'fridge for another taste comparison later this afternoon. Hoping the additional week and being cold will improve the comparison to the actual Piraat.

Got a ton of assorted Cantex and EMT conduit to finish running the electrical line along the deck to put in a few GFIC outlets for smoking meat and/or running a pump, pressure washer etc. Nothing too complicated and it's a gorgeous day.

On Tuesday the electrician arrives to hook up a 20 amp circuit from the breaker box to the junction box. Juice!

On Tuesday the electrician arrives to hook up a 20 amp circuit from the breaker box to the junction box. Juice!

Sanitised my new keg ready for my single hop DDH Nectaron hazy.

Cut my new 3/16 beer lines to lengthy in preparation to re-line my kegerator at the weekend.

Did the second set hop on my IPA via hop bong.

Cut my new 3/16 beer lines to lengthy in preparation to re-line my kegerator at the weekend.

Did the second set hop on my IPA via hop bong.

Rough chopped 10 ounces of espresso beans, drained the yeast cake and trub and added the beans to my coffee porter, then set the temp to 40, drained the trub and yeast cake on my black IPA and added 2 ounces of citra hops, washed and sanitized 50 bottles, then bottled an Irish Red..

Attachments

Similar threads

- Replies

- 66

- Views

- 2K

- Replies

- 20

- Views

- 1K

- Replies

- 55

- Views

- 2K