Did you just drop a whole bean in, put it in a bag or use extract/liquor soaked bean?Pulled a sample of my chocolate covered coconut stout and added an extra vanilla bean to the keg. Perfect now!View attachment 658599

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What I did for beer today

- Thread starter iaefebs

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I cut it in half, and then lengthwise. Then, I scraped the inside with a knife on a sanitized paper towel to get it open and put it in the keg.

Did you just drop a whole bean in, put it in a bag or use extract/liquor soaked bean?

- Joined

- Feb 19, 2017

- Messages

- 979

- Reaction score

- 1,238

I decided that I like seasonal brewing, at least for now. That is, winter is time for an Anchor Steam (listened to a pod cast with the head brewer with some tips and tricks), a couple of Czech lagers, and a batch of sake (and if I'm doing a sake, I might as well pitch a sorachi ace hopped all grain batch on top of the dregs as a super starter). I have an unused bathroom that maxes out at 60F ambient these days (the temp for both Steam and sake), and a garage that will work for colder lagering.

Last night did a 4 gallon simple 8 plato Czech style 3 step mash (couple pounds each of munich and Vienna, a pound of carafoam 'cause it was handy, used up tettnanger hops), and doing a split yeast test between 34/70 Augustiner and Anchor Steam lager yeasts. Much prefer the 34/70 vs Urkel in 2 different previous tests. Doing the yeast off with 34/70 and Steam because I have a Steam coming up this week on the brew schedule.

Summer is time to play with some Kvieks in the garage. Not that there is much of a summer here in Seattle but it does get over standard ale temperatures.

I can do English ales somewhere in the house or garage pretty much year round.

I kinda look forward to the seasons, reviving yeasties from the bank. Have a file of recipe candidates I add to as the mood strikes, and then figure out what to brew at the right time of year.

One day I may get a temperature controlled freezer or gycol jacketed fermenter, but for now I enjoy having the seasons add some guidance to the brew schedule.

Last night did a 4 gallon simple 8 plato Czech style 3 step mash (couple pounds each of munich and Vienna, a pound of carafoam 'cause it was handy, used up tettnanger hops), and doing a split yeast test between 34/70 Augustiner and Anchor Steam lager yeasts. Much prefer the 34/70 vs Urkel in 2 different previous tests. Doing the yeast off with 34/70 and Steam because I have a Steam coming up this week on the brew schedule.

Summer is time to play with some Kvieks in the garage. Not that there is much of a summer here in Seattle but it does get over standard ale temperatures.

I can do English ales somewhere in the house or garage pretty much year round.

I kinda look forward to the seasons, reviving yeasties from the bank. Have a file of recipe candidates I add to as the mood strikes, and then figure out what to brew at the right time of year.

One day I may get a temperature controlled freezer or gycol jacketed fermenter, but for now I enjoy having the seasons add some guidance to the brew schedule.

Tapped the WF lager I did 10 days ago; tasting on kegging was grassy as poopy, but carbonation seems to have taken care of it (no I don't know why) and it tastes great. Has a bit of skunkiness in the aroma, reminiscent of a green bottle beer, but it's not unpleasant. Malt came through great in the flavor, and I'm still loving Comet as my new bittering hop. Now if Santa will only bring me a new grain mill.....

Found out my CO2 went from 2/3 full to empty overnight. So what I will do for beer, TOMORROW, is get a new tank and check for leaks.

I carb in keg before moving to keezer and gas, so I was able to pour off 1/2 a growler of mostly carbed IPA for family today.

I carb in keg before moving to keezer and gas, so I was able to pour off 1/2 a growler of mostly carbed IPA for family today.

Be careful not to pour too much that the pressure drops enough that the lid looses it's seal.Found out my CO2 went from 2/3 full to empty overnight. So what I will do for beer, TOMORROW, is get a new tank and check for leaks.

I carb in keg before moving to keezer and gas, so I was able to pour off 1/2 a growler of mostly carbed IPA for family today.

With a leak that fast it could be easy to find. Starsan works for tracking down leaks, but how easy it foams it can difficult with small leaks. You should be able to find a thread of two here on HBT with good advice on tracking down leaks. Hope you are able find your leak quickly.

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

- Joined

- Feb 19, 2017

- Messages

- 979

- Reaction score

- 1,238

Making an BYO American version clone of the Fuller's London Porter (uses a mix of chocolate and black malt, plus roasted barley). I'm going to use WLP017 Whitbread because I've cultured up a 2L starter so I can pitch and add to the yeast bank.

Making an BYO American version clone of the Fuller's London Porter (uses a mix of chocolate and black malt, plus roasted barley). I'm going to use WLP017 Whitbread because I've cultured up a 2L starter so I can pitch and add to the yeast bank.

Is the first time using WLP017, if so how do you like it? I see they have available on yeastman and thinking about trying it. Just recently brewed with all of my vault purge yeasts but have not tried the beer made with WLP033 and WLP022 yet.

Dave Sarber

Unindicted Co-conspirator

Checked SG's on batches in progress. Pressure canning a batch of starter wort. Kickin' back.

Heading down to my buddy's brewpub tonight, he wants to sell his old grain mill (three roller with stand, motor, and hopper) and we're going to take it home. After visiting and quaffing a few of his great beers. Don't know where I'd be without him, he's been my mentor, part-time boss, friend, and a**-kicker to get me to brew better beers for three years now. Gonna be a good time.

Found the CO2 leak in my system (I hope) and while I was getting a full tank at the LHBS, I felt compelled to buy the grain for a DIPA and an Imperial Stout (Santa brought a grain mill)!

Cleaned

- Joined

- Feb 19, 2017

- Messages

- 979

- Reaction score

- 1,238

I've done two or three WLP017 so far. Eg, one of the Whitbread strain. What I've read on the interwebs is that S-04 is from the Whitbread "dry" strain. Suregork has sequenced WLP017 and WY1098 as the same or equivalent strains. There are probably other strains in the full blown Whitbread yeast.Is the first time using WLP017, if so how do you like it? I see they have available on yeastman and thinking about trying it. Just recently brewed with all of my vault purge yeasts but have not tried the beer made with WLP033 and WLP022 yet.

Anyhoo, I like it. It is pretty fine like sand, while I am coming to think I prefer more flocculant yeasts with more "snow globe" action like 002 or Notty. Since it's a Fullers knock off, I should really be using Pub (which I prefer over 002 after several tests) or WLP085 (which is a mix rumored of 002 & 006 or 007). Since I was culturing up the WLP017 for my yeast bank at the same time I was brewing the Fullers clone....

Maybe we should start a vault purge thread? I got the WLP017, WLP023 and the WLP026 (and previously got a vault release of WLP037). Still playing with the 17 and 23 to see if they make it on to my eventual English ale short list. I gave up on 37 after multiple tries as it is way beyond my homebrewer abilities to make decent and repeatable beers. Haven't liked the 026 as it tastes POF to me (has the STA1 gene).

- Joined

- Feb 19, 2017

- Messages

- 979

- Reaction score

- 1,238

Can you share the brewpub name?Heading down to my buddy's brewpub tonight, he wants to sell his old grain mill (three roller with stand, motor, and hopper) and we're going to take it home. After visiting and quaffing a few of his great beers. Don't know where I'd be without him, he's been my mentor, part-time boss, friend, and a**-kicker to get me to brew better beers for three years now. Gonna be a good time.

I rarely get out but always happy to have a recommendation in the SEattle area. My favorite is Machine House Brewery. Gotta get to Post Doc Brewing in Redmond one of these days...

It's Rail Hopp'n in Auburn, on Main Street. He used to run it out of his garage but last year got some nice digs next to Oddfellas. If you go, and Billy Jack (the owner) is there, tell him Becky sent you. And try the Red Caboose IPA, it's a Mosaic Smash with raspberries that is just to die for.Can you share the brewpub name?

I rarely get out but always happy to have a recommendation in the SEattle area. My favorite is Machine House Brewery. Gotta get to Post Doc Brewing in Redmond one of these days...

Yesterday: Brewed a 10gal batch of beer, well actually brewed 9gals and turned it into 5gal of IPA then added a gallon of water to the other 4gals to make a pale/golden ale.

Today: Weather around here got just cold enough that it now takes forever to make RO water now so I had to finish collecting my brewing RO water for next batch today. Normally I can make enough while I am brewing. Next time I might use my IC and the RIMS to warm the incoming water to the RO system to see if that speeds up the process.

I had recently reslanted wlp037 and have the yeast in the fridge. I keep going back and forth about brewing with it or not. I only brewed with it once, I was not to happy with it at first but the beer sort of grew on me over time. WLP038 is sort of similar but does not attenuate as much and after that one I am kind of getting a taste for phenolic beer again. I have some wlp515 chilling might do a batch and split between wlp515 and wlp037.

I did not get phenols from WLP026 but I got some banana which is not my favorite flavor. I seen reports of it being an over attenuator which makes me a bit nervous if it contaminates some other yeast. Without the POF clove flavor it might be hard to identify. I thought I was able to stop it from over attenuation by mashing high and crashing the beer when it was attenuated to where I wanted it, but that beer got foaming in the keg so it might of been still working. I got a slight vanilla flavor from that beer and would not mind figuring a way to get it stronger without getting more banana.

I had a pint of my wlp033 bitters and seems like it might be an OK yeast, a little fruitiness in flavor and aroma. Will try it again in a week or two.

Today: Weather around here got just cold enough that it now takes forever to make RO water now so I had to finish collecting my brewing RO water for next batch today. Normally I can make enough while I am brewing. Next time I might use my IC and the RIMS to warm the incoming water to the RO system to see if that speeds up the process.

Thanks for the tip on wlp017, if it is basically the same as 1098 might try that instead so I don't need to slant it incase I like it.I've done two or three WLP017 so far. Eg, one of the Whitbread strain. What I've read on the interwebs is that S-04 is from the Whitbread "dry" strain. Suregork has sequenced WLP017 and WY1098 as the same or equivalent strains. There are probably other strains in the full blown Whitbread yeast.

Anyhoo, I like it. It is pretty fine like sand, while I am coming to think I prefer more flocculant yeasts with more "snow globe" action like 002 or Notty. Since it's a Fullers knock off, I should really be using Pub (which I prefer over 002 after several tests) or WLP085 (which is a mix rumored of 002 & 006 or 007). Since I was culturing up the WLP017 for my yeast bank at the same time I was brewing the Fullers clone....

Maybe we should start a vault purge thread? I got the WLP017, WLP023 and the WLP026 (and previously got a vault release of WLP037). Still playing with the 17 and 23 to see if they make it on to my eventual English ale short list. I gave up on 37 after multiple tries as it is way beyond my homebrewer abilities to make decent and repeatable beers. Haven't liked the 026 as it tastes POF to me (has the STA1 gene).

I had recently reslanted wlp037 and have the yeast in the fridge. I keep going back and forth about brewing with it or not. I only brewed with it once, I was not to happy with it at first but the beer sort of grew on me over time. WLP038 is sort of similar but does not attenuate as much and after that one I am kind of getting a taste for phenolic beer again. I have some wlp515 chilling might do a batch and split between wlp515 and wlp037.

I did not get phenols from WLP026 but I got some banana which is not my favorite flavor. I seen reports of it being an over attenuator which makes me a bit nervous if it contaminates some other yeast. Without the POF clove flavor it might be hard to identify. I thought I was able to stop it from over attenuation by mashing high and crashing the beer when it was attenuated to where I wanted it, but that beer got foaming in the keg so it might of been still working. I got a slight vanilla flavor from that beer and would not mind figuring a way to get it stronger without getting more banana.

I had a pint of my wlp033 bitters and seems like it might be an OK yeast, a little fruitiness in flavor and aroma. Will try it again in a week or two.

Not today but late last night got on YVH and ordered two pounds of Mosaic. It's my very first favorite hop for IPA's, and it finally seems to be falling out of favor with all the new varieties out. Only $18/lb for the 2018 crop; YVH takes great pains to keep their hops fresh so last year's crop doesn't bother me a bit. Two pounds will last me a good long time. Now crossing my fingers they get here before New Years, planning a nice Smash on the 1st to celebrate 2020. That's the really nice thing about living in WA, I get my hops fast!

brew day tomorrow so today i've already put the yeast starter in the fridge to settle, replaced the di resin in my water system and cleaned some new tc gaskets/fittings. later on is filling the hlt, weighing/milling grain, weighing out brew salts and preheating the hlt to jump start tomorrow's brew.

I'm getting ready to install an RO system but was not aware of cold water affecting the output volume.Not today but late last night got on YVH and ordered two pounds of Mosaic. It's my very first favorite hop for IPA's, and it finally seems to be falling out of favor with all the new varieties out. Only $18/lb for the 2018 crop; YVH takes great pains to keep their hops fresh so last year's crop doesn't bother me a bit. Two pounds will last me a good long time. Now crossing my fingers they get here before New Years, planning a nice Smash on the 1st to celebrate 2020. That's the really nice thing about living in WA, I get my hops fast!

Washing bottles, cleaning kegs.

I don't recall where I read it but it sure does for me. I have a 50GPD system and get closer to 3gal per hour in the middle of summer, but yesterday it was less than 1gal per hour. Measured my tap water outside at 58F, guess it is in the 70s during summer.I'm getting ready to install an RO system but was not aware of cold water affecting the output volume.

I have a portable system that I use outside so that might be part of the issue, might work better inside.

Robert65

Major Obvious (recently promoted)

Input pressure and temperature both affect output rate. Warmer feed water will run faster, but any more than lukewarm will harm the membrane (definitely keep comfortably below 100°F.) I have a portable unit I run off my utility sink, so in the winter I open the cold faucet full on and then ease up the hot faucet until I have room temperature feed. Year round that keeps it running 15-20 minutes per gallon with super low TDS.

As I understand it, not just input pressure matters, but the differential between input and output affects not only flow rate but the rejection efficiency of the membrane, so it will perform better just running the output into a bucket or jug rather than a bladder tank that provides back pressure.

As I understand it, not just input pressure matters, but the differential between input and output affects not only flow rate but the rejection efficiency of the membrane, so it will perform better just running the output into a bucket or jug rather than a bladder tank that provides back pressure.

Check your water report to see if you have chloramine in your water, if so get an appropriate setup and consider a lower output unit as it will increase the contact in your carbon filters. Your flow rate thru the filters is the combination of the RO output plus 4x that in waste.I'm getting ready to install an RO system but was not aware of cold water affecting the output volume.

When I first bought my components my local water company did not use chloramine but they switched so I swapped out my 75GPD RO membrane for 50 and had to add another carbon filter. Even at 50GPD it is detectable at the lowest level of my home water test kit, so I add a little Camden to play it safe.

Ordered a new bag for my shiny new Mash & Boil. Also finally ordered an immersion chiller! No more baths!

Brewed up an extract bitter with plenty of EKG. I still like doing simple extracts once in awhile, and wanted to test out Maris otter LME.

Brewed up an extract bitter with plenty of EKG. I still like doing simple extracts once in awhile, and wanted to test out Maris otter LME.

I think you may have responded to the wrong post....made my brain hurt.I'm getting ready to install an RO system but was not aware of cold water affecting the output volume.

- Joined

- Feb 19, 2017

- Messages

- 979

- Reaction score

- 1,238

very nice

I am doing an Anchor Steam clone. Been listening to podcasts with Fritz Maytag and the new head brewer. Seems like one of their tricks is a secondary fermentation with ~20% krausen. So, I'm gonna do that.

Have to take advantage of time off over the holidays combined with natural lager temperatures in various rooms in the house and garage to do some lagers. To me, Anchor Steam, which I first tried in 1979, is THE benchmark. I'm not saying it's the best beer in the world, but it sets the bar and if you want to be a player the beer should be equivalently good to Anchor Steam.

I've got to back out the brewing schedule and business travel for when I can do 4 gallons of sake this season. Stay tuned for that

I am doing an Anchor Steam clone. Been listening to podcasts with Fritz Maytag and the new head brewer. Seems like one of their tricks is a secondary fermentation with ~20% krausen. So, I'm gonna do that.

Have to take advantage of time off over the holidays combined with natural lager temperatures in various rooms in the house and garage to do some lagers. To me, Anchor Steam, which I first tried in 1979, is THE benchmark. I'm not saying it's the best beer in the world, but it sets the bar and if you want to be a player the beer should be equivalently good to Anchor Steam.

I've got to back out the brewing schedule and business travel for when I can do 4 gallons of sake this season. Stay tuned for that

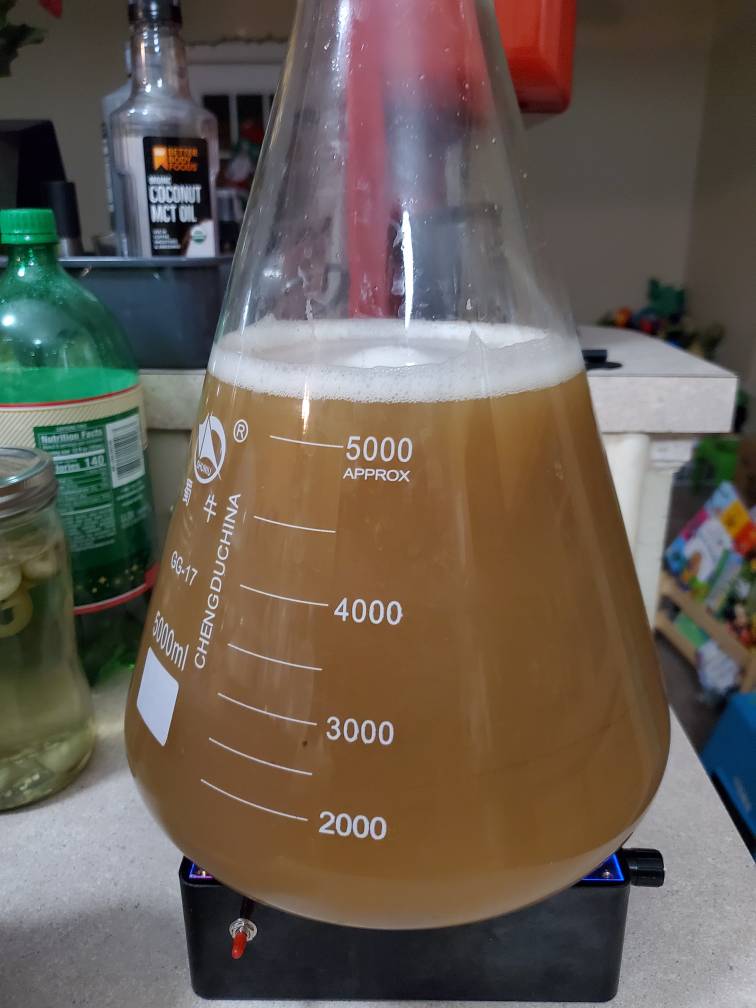

Brewing a westlevern clone. Mill innovations lolView attachment 659296

Nice! You need to revive the ghetto brew setups post

Similar threads

- Replies

- 66

- Views

- 2K

- Replies

- 20

- Views

- 1K

- Replies

- 55

- Views

- 2K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)

![20191226_140919[1].jpg 20191226_140919[1].jpg](https://cdn.homebrewtalk.com/data/attach/599/599821-20191226-140919-1-.jpg)

![20191226_145716[1].jpg](https://cdn.homebrewtalk.com/data/attachments/599/599823-3853039cc4a452787a8fae82a1feaa81.jpg)

![20191226_140953[1].jpg](https://cdn.homebrewtalk.com/data/attachments/599/599824-24b1314bc758d3c901d04570d795c7bd.jpg)