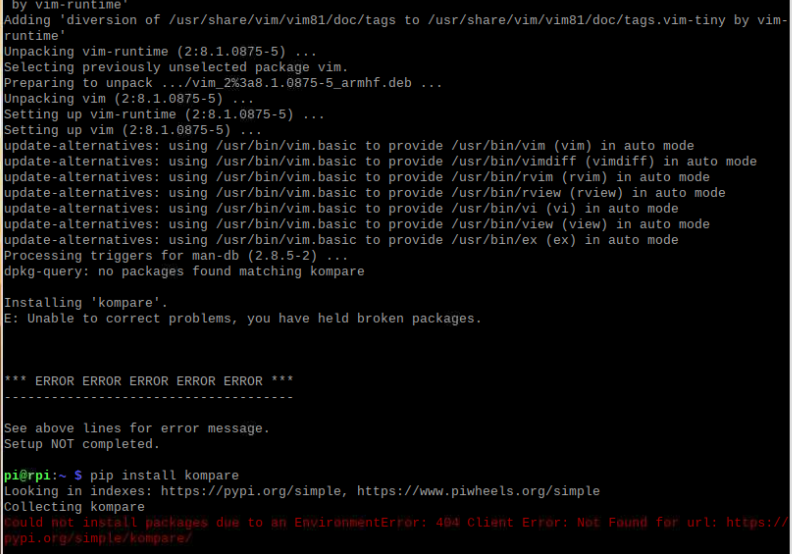

I just don't know if this is for me. After a clean install and 2 reinstalls, no beers will show up on my screen now.

Flow meters still aren't working either.

I turned the logging level up and this is what I have:

Raspberry Pints Log

Date Process Category Text Occurances

2020-11-24 20:47:50 FlowMonitor D Sending Status;N;-1;0;0;0;0;0;0;0;| 1072

2020-11-24 20:43:08 FlowMonitor D listening to Arduino 1

2020-11-24 20:43:08 FlowMonitor D Arduino says: C:6:3:5:7:9:0:0:0:300:200:30:250:0:0:1| 1

2020-11-24 20:43:08 FlowMonitor D Waiting for Config Response 1

2020-11-24 20:43:08 FlowMonitor D Arduino config, about to send: C:6:3:5:7:9:0:0:0:300:200:30:250:0:0:1| 1

2020-11-24 20:43:08 FlowMonitor D getting config data for Arduino 1

2020-11-24 20:43:08 FlowMonitor D Arduino alive... 1

2020-11-24 20:43:07 FlowMonitor D Adding 28-011927f10bdc Temp[6.9] low:0.0 high:212.0 1

2020-11-24 20:43:06 FlowMonitor D waiting for Arduino to come alive 1

2020-11-24 20:43:06 FlowMonitor I 1Wire Temperature Thread 1 is Running 1

2020-11-24 20:43:05 PintDispatch I Not Configured to run Fan 1

2020-11-24 20:43:05 PintDispatch I Fan Control fanControl1 is Running 1

2020-11-24 20:43:05 FlowMonitor D Creating Serial Listener 1

2020-11-24 20:43:05 FlowMonitor D resetting Arduino 1

2020-11-24 20:43:05 PintDispatch I starting fan control 1

2020-11-24 20:43:05 PintDispatch I starting command server 1

2020-11-24 20:43:05 PintDispatch I starting device monitors... 1

2020-11-24 20:43:05 PintDispatch I starting WS server 1

I suppose I can try adding the resistors to the meters although

@garzlok is using the same meters and they seem to work without them.

Is there anything else I can do to troubleshoot this?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)