You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[Version 2 Release] RaspberryPints - Digital Taplist Solution

- Thread starter skemp45

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

It works, thanks.I hope that works. This is the third one that gave me the same error, all came as an export from Beersmith 3.

The issue is there is a ' in the beer name. I will have to add logic to escape the name.

Interesting, I just happened to drill out one of my flowmeters. In the one without the drilled opening, I can hardly get any foam - it pours so slowly. The one I drilled out pours really fast and foams up a little. I may have to mess with line lengths a little.Sorry to dig up this old comment, but I am having the same issue with foaming because or turbulence. I initially used the go-to beer line length calculator and found that 5.5 should be the perfect length. I have about 2 ft of line before the meter so I can reach any keg I need and extended out to 5.5 feet after the meter and still have 2-3 inches of foam. I then went directly from keg to tap with 5.5 and the pours are near perfect. From what I saw you write in a post, you finally went with about 10 ft of line to allow the beer to settle down after the meters? I am using these meters GREDIA 1/4" Quick Connect Water Flow Sensor Food-Grade Switch Hall Effect Flowmeter Fluid Meter Counter 0.3-6L/min (Pack of 2): Amazon.com: Industrial & Scientific

I do vary the PSI depending on some beer styles and didn't want to have to swap out lines when I needed a longer/shorter line to support different pressures.

I just committed the fix, if you get latest it the XML should upload.This is the third one that gave me the same error, all came as an export from Beersmith 3.

You can get latest by running the installer or going to the Install Page (under admin) and hit Get Latest RPints

esdill

Well-Known Member

Thanks!I just committed the fix, if you get latest it the XML should upload.

You can get latest by running the installer or going to the Install Page (under admin) and hit Get Latest RPints

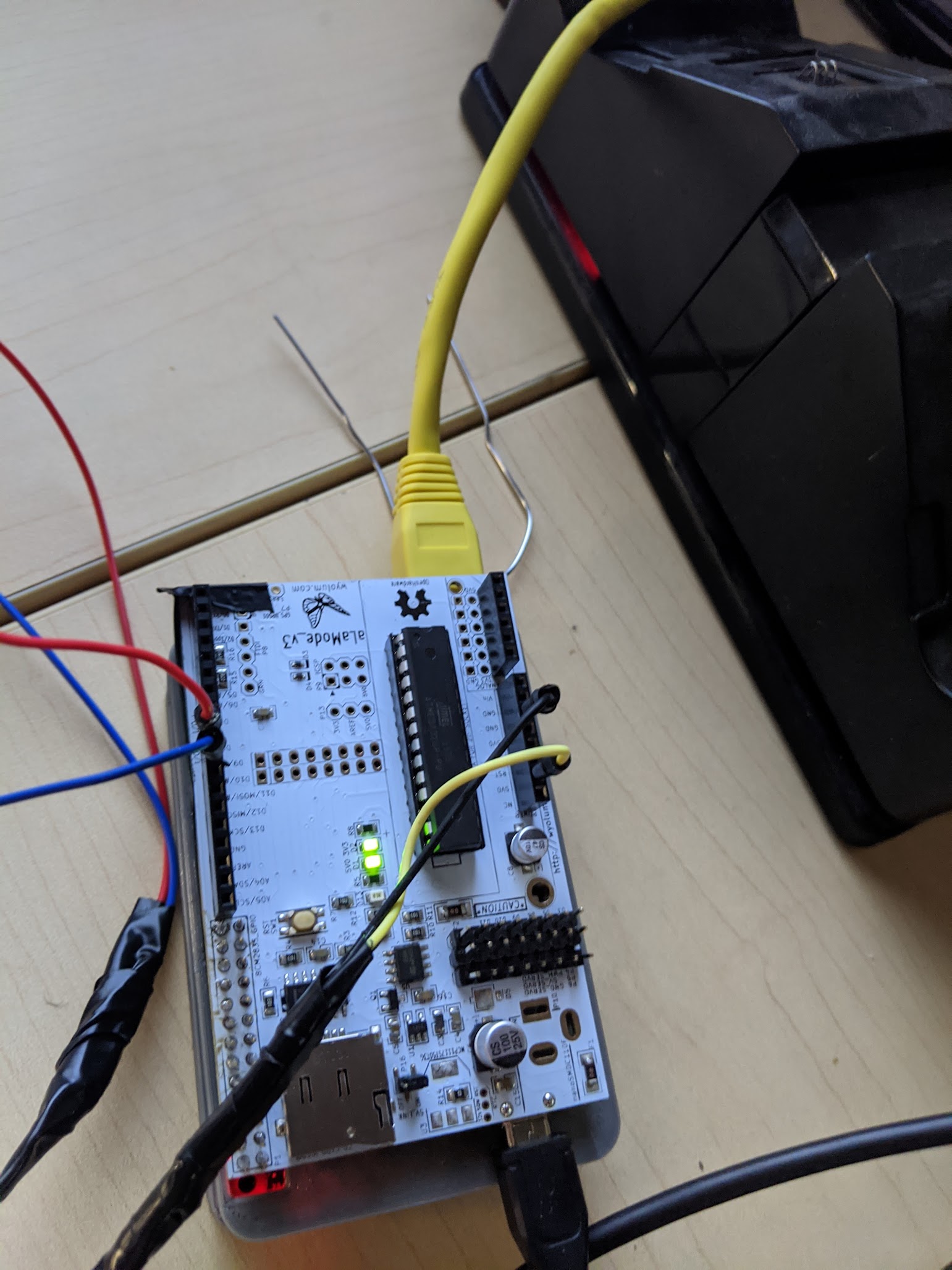

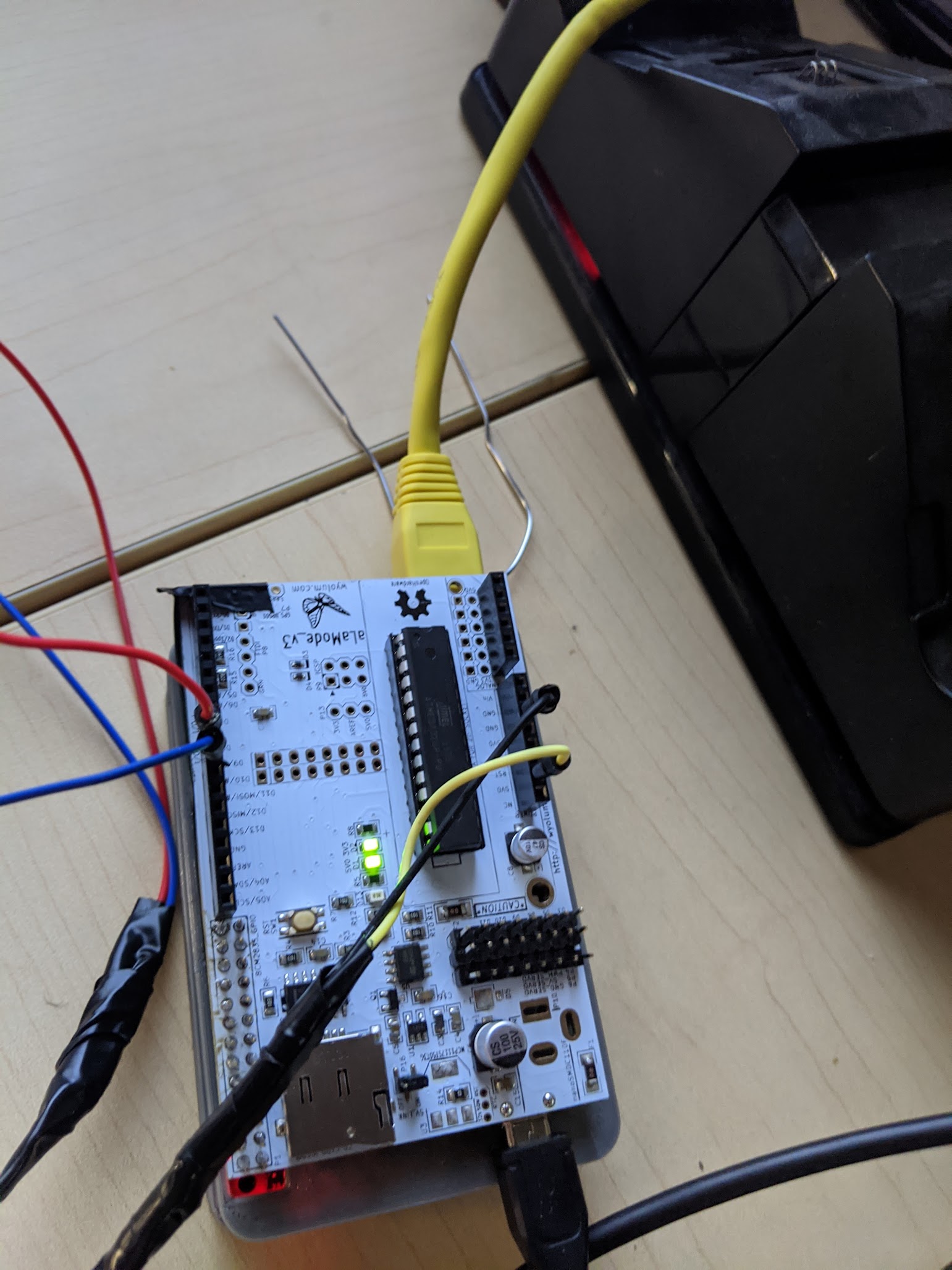

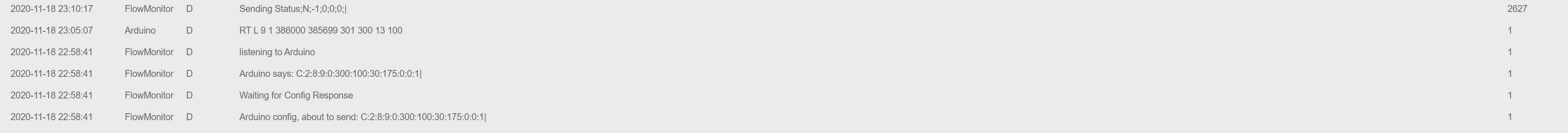

View attachment 706928

DoubleA_Brewing

Accidentally Make Good Beer

Hello Everyone!!!

I just set up my first Raspberry Pints using the install script, but I have a few questions..

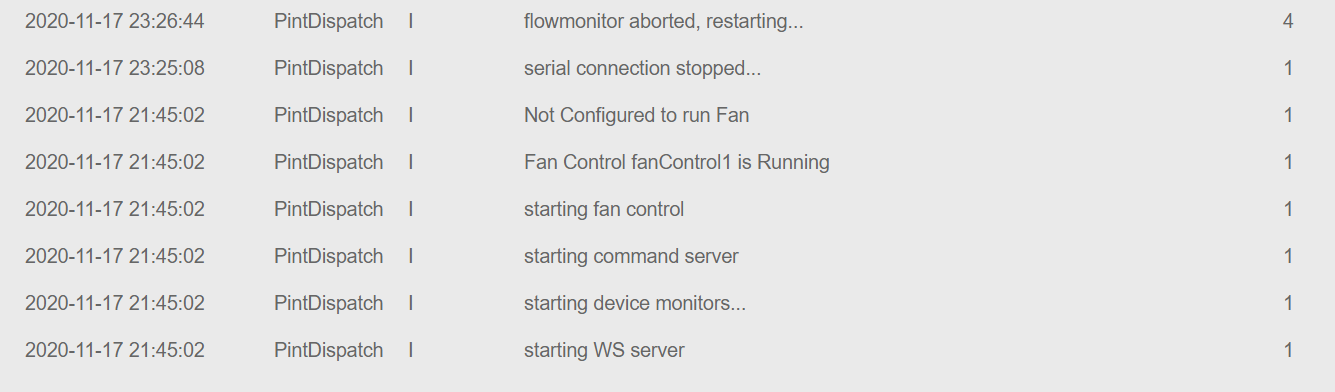

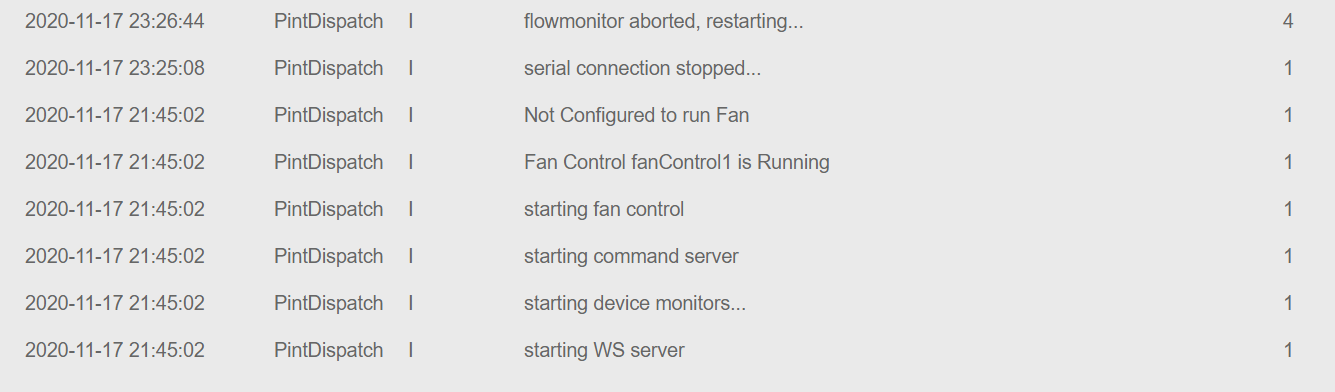

I am using an Alamode board mounted on a Pi 2B with the 2 swissflo meters. My issue/question I have is how can I get the pi to talk with the Alamode board? My flow meters aren't workingas can be seen in the screenshot from my rpints log.. I tried also compiling and uploading the raspberrypints.ino file in the arduino program using alamode board and tty/S0 as my options. Any help or walkthrough troubleshooting with me on this would be amazing!

Ok second weird item I have is whenever I open the file manager it pops up and immediately closes it only started doing this after I installed rpints on it... Has anyone else had this happen?

I have read quite a few posts on this thread but just can't figure out those two items..

The picture of my Alamode board wiring scheme is:

Yellow: 5V

Black: GND

Red: Flow Meter 1

Blue Flow Meter 2

Thank you for everyone who is maintaining this it is an awesome feature to add to my homebrewing setup!! once I get everything up and running I will post a picture!

I just set up my first Raspberry Pints using the install script, but I have a few questions..

I am using an Alamode board mounted on a Pi 2B with the 2 swissflo meters. My issue/question I have is how can I get the pi to talk with the Alamode board? My flow meters aren't workingas can be seen in the screenshot from my rpints log.. I tried also compiling and uploading the raspberrypints.ino file in the arduino program using alamode board and tty/S0 as my options. Any help or walkthrough troubleshooting with me on this would be amazing!

Ok second weird item I have is whenever I open the file manager it pops up and immediately closes it only started doing this after I installed rpints on it... Has anyone else had this happen?

I have read quite a few posts on this thread but just can't figure out those two items..

The picture of my Alamode board wiring scheme is:

Yellow: 5V

Black: GND

Red: Flow Meter 1

Blue Flow Meter 2

Thank you for everyone who is maintaining this it is an awesome feature to add to my homebrewing setup!! once I get everything up and running I will post a picture!

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

in python/Config.py changeMy flow meters aren't workingas can be seen in the screenshot from my rpints log.. I tried also compiling and uploading the raspberrypints.ino file in the arduino program using alamode board and tty/S0 as my options. Any help or walkthrough troubleshooting with me on this would be amazing!

#logging settings for flowmon

config['flowmon.debug' ] = False#True

#logging settings for pintdispatch

config['dispatch.debug' ] = False#True

to

#logging settings for flowmon

config['flowmon.debug' ] = True

#logging settings for pintdispatch

config['dispatch.debug' ] = True

then restart the python

sudo /etc/init.d/flowmon restart

This will log more information to the log

Next to upload to the alamode manually you need to stop the python first otherwise you will get weird errors

sudo /etc/init.d/flowmon stop

DoubleA_Brewing

Accidentally Make Good Beer

I am guessing this is good?in python/Config.py change

What next? haha

Looks like you have Rpints configured for pins 8 and 9, you should now be able to "pour" a beer and see a pour register in the pour list and the logWhat next? haha

DoubleA_Brewing

Accidentally Make Good Beer

Pins 8&9 are D8 and D9 correct? If so nothing happened for either... I'm going to check connections, restart the pi and try again.Looks like you have Rpints configured for pins 8 and 9, you should now be able to "pour" a beer and see a pour register in the pour list and the log

that is how mine is setup.Pins 8&9 are D8 and D9 correct?

Make sure you have good power to the flow meters. I must have bumped my pins at one point because it stopped registering pours, a quick volt test between my pins for gnd and 5v let me know that was the issue

DoubleA_Brewing

Accidentally Make Good Beer

that is how mine is setup.

Make sure you have good power to the flow meters. I must have bumped my pins at one point because it stopped registering pours, a quick volt test between my pins for gnd and 5v let me know that was the issue

Thanks for the help so far! I checked all my connections and I had a loose 5V wire, but I still didn't get a triggered pour.. The new issue is the log is no longer updating and my alamode status light isn't constantly blinking like before. I've restarted everything tried turning on flowmon and still nothing. The last log I had was from last night see image. Any Ideas?

Last edited:

I see a RT L 9 which indicates a reset Tap pin 9 because it only got 13 pulses out of the 100 needed to register a pour.The last log I had was from last night see image. Any Ideas?

so it got some phantom pulses at one point

did you try

sudo /etc/init/flowmon restart

esdill

Well-Known Member

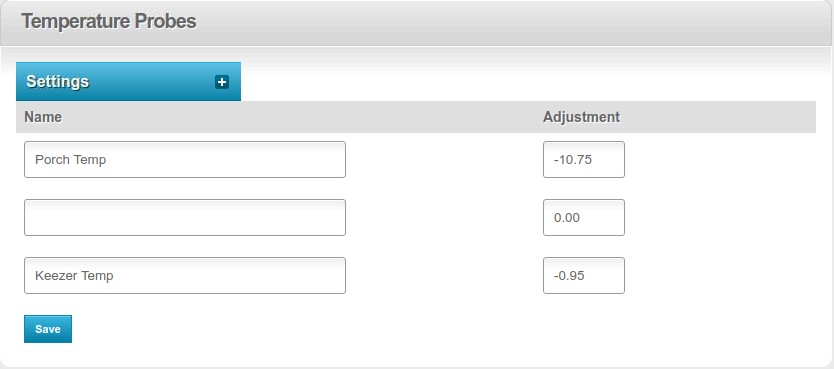

One of my temp probes failed, I have now replaced it. I have 3 probe values showing in the upper right corner (one with no description and a value of 0.0 F degrees). Will the "empty" probe reading eventually drop off the screen, or is there something I will need to do to remove it manually?

you will have to manually delete it from the database. or wait a few days till I can implement a delete buttonis there something I will need to do to remove it manually?

DoubleA_Brewing

Accidentally Make Good Beer

Is there a way to change the rate at which it samples so I can have more data points for accurate triggers and measurements? What counts do you normally see on a 16 oz pour?I see a RT L 9 which indicates a reset Tap pin 9 because it only got 13 pulses out of the 100 needed to register a pour.

so it got some phantom pulses at one point

did you try

sudo /etc/init/flowmon restart

the arduino doesn't sample, when it detects a pulse it counts it so the sampling is on the flow meterIs there a way to change the rate at which it samples

mine is setup for 7000 pulses per ounce so 112000 pulses per 16 ozWhat counts do you normally see on a 16 oz pour?

DoubleA_Brewing

Accidentally Make Good Beer

I have the swissflo SF800s supposed to be a K factor of 6100 pulse/L so about 171 pulses per ounce... What flow meters do you have to get that sample count?mine is setup for 7000 pulses per ounce so 112000 pulses per 16 oz

Sorry wrong label/math, its been a day.What flow meters do you have to get that sample count?

7000 pulses per gallon 54.6875 per oz

DoubleA_Brewing

Accidentally Make Good Beer

Hmmm.... I wonder if cable length and non shield cable is playing a role because none of my pours read a consistent output even though I am pouring the same amount... I also have the 5v and GND tied together (not to each other) respectively for each meter... I probably have about 15ft of cable 22ga wire non shielded..Sorry wrong label/math, its been a day.

7000 pulses per gallon 54.6875 per oz

I appreciate all your help!! We are so close to the finish line I can taste it!!

im not at 15ft but I have 8 taps sharing the 5v and gnd and their signal wires all electrical tapped together using non shielded wire without issueprobably have about 15ft of cable 22ga wire non shielded..

could you disconnect one from the power and try? what connections do you use to the flow meters for the beer lines? you might be getting turbulence that is causing the inconsistency.

fwiw, I have roughly 13 feet total wire lengths between my SF800s and the AlaMode, each meter with its own (unshielded) 3-wire route for signal, power and ground from end to end. Same for the array of ds18b20 temperature sensors. No issues.

Voltage matters. Make sure 5 volts is really 5 volts...

Cheers!

Voltage matters. Make sure 5 volts is really 5 volts...

Cheers!

DoubleA_Brewing

Accidentally Make Good Beer

im not at 15ft but I have 8 taps sharing the 5v and gnd and their signal wires all electrical tapped together using non shielded wire without issue

Thanks for all the tips!! We got it!! It's working every 16oz pour roughly 2300 pulses!! So first I'm an absolute idiot, flow meters were physically backwards.... Just had to switch flow direction and BAM!!! Thank Thank Thank you I will post pictures once I get it all pretty! Y'all are a huge help!

ill add that to my list of things to check when someone else is having issues.flow meters were physically backwards

DoubleA_Brewing

Accidentally Make Good Beer

Has anyone on here used a 5V pressure sensor for reading the PSI of the tank to determine tank level? I am considering trying to implement this rather than weighing just reading in my pressure and above a certain range is ok, and below a certain PSI is low tank. If I get this to work would anyone be interested? My plan would be to install the pressure sensor on a "T" connector that connects to the tank pressure gauge.

- Joined

- Sep 8, 2020

- Messages

- 139

- Reaction score

- 9

I am at a loss on what to do next. I have a new build and I cannot get consistent pour readings.

Initially, I think I had a bad serial cable from my RP to my Uno R3. Replaced that and still, no pours being registered. I have checked the continuity all the way from the meters to the 5v, ground and signal wires and everything is good. I have 5V at the meters as well. Flow meters are facing the correct direction as well

If I reboot the RP, the pours seem to just show up:

Also, after rebooting the RP, the assigned beers are losing assignment:

The R3 lights are flashing:

Tx and Rx are flashing in a staggered unison.

I am also using separate power sources for the RP and R3.

Initially, I think I had a bad serial cable from my RP to my Uno R3. Replaced that and still, no pours being registered. I have checked the continuity all the way from the meters to the 5v, ground and signal wires and everything is good. I have 5V at the meters as well. Flow meters are facing the correct direction as well

If I reboot the RP, the pours seem to just show up:

Also, after rebooting the RP, the assigned beers are losing assignment:

The R3 lights are flashing:

Tx and Rx are flashing in a staggered unison.

I am also using separate power sources for the RP and R3.

Attachments

Last edited:

Has anyone on here used a 5V pressure sensor for reading the PSI of the tank to determine tank level? I am considering trying to implement this rather than weighing just reading in my pressure and above a certain range is ok, and below a certain PSI is low tank. If I get this to work would anyone be interested? My plan would be to install the pressure sensor on a "T" connector that connects to the tank pressure gauge.

Good luck, but to have any accuracy at all you will need to account for these pressure vs temperature curves...

There are some folks that have been looking at load-cell based solutions, which frankly makes the most sense for this application...

Cheers!

im going through this same thing right now, though I haven't made an Arduino changes in a long time so I don't think its code, but I haven't tracked down the issue yet.If I reboot the RP, the pours seem to just show up:

Also, after rebooting the RP, the assigned beers are losing assignment:

The taps are clearing because the signal is coming in so fast the Arduino registering a kick instead of a pour you can disable that through configuration

- Joined

- Sep 8, 2020

- Messages

- 139

- Reaction score

- 9

im going through this same thing right now, though I haven't made an Arduino changes in a long time so I don't think its code, but I haven't tracked down the issue yet.

The taps are clearing because the signal is coming in so fast the Arduino registering a kick instead of a pour you can disable that through configuration

View attachment 707644

Ok, I made that change.

This is probably really stupid, but I stopped following the online docs once I used the automated install.

Do I need to follow this:

http://raspberrypints.com/byo/step-9-configure-pi-hardware-flow-meters-wflow-meters/

I am using an Uno R3 and I definitely do not have a 5V_Link jumper.

I also took my Red from the meters to 5V, Black to GND and the Yellow (signal wires) to the digital inputs.

By following the instructions online, I was getting about 8V to the meters.

[...]

I also took my Red from the meters to 5V, Black to GND and the Yellow (signal wires) to the digital inputs.

By following the instructions online, I was getting about 8V to the meters.

8V? Where is that coming from? No bueno.

Do you have pull-ups on the meter data lines to your Uno 5V or are you relying on internal pull-ups? Which I assume are enabled - but maybe they're not? @RandR+ ?

Cheers!

Similar threads

- Replies

- 1

- Views

- 826

- Replies

- 6

- Views

- 4K

- Replies

- 21

- Views

- 4K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)