Lucky_Chicken

Well-Known Member

You see some commercial breweries use them like this small one: Steam condenser for the boil kettle. Cold water sprays in and condenses the steam from the kettle so it can just run into the drain instead of smelling up the neighborhood.

Quote from Kal:

For home use I don't see this really working because:

- You'd need to run water through it during the entire boil (very wasteful).

- Nothing is 100% efficient so you'd still get *some* humidity in the room which will build up. How much, I don't know.

- Heat: None of the heat escapes the room so the room would likely get very warm over time.

I'm still curious to hear about experiences with a steam condenser however. It's an interesting idea.

Kal

end quote

My plan will just get most of the steam, in the summer its not a big deal I'll just leave a window open and in the winter a little humidity will be good!

for running water my plan was to recycle water from a large bucket with a pond pump.

with my system yes heat would build up and again in the winter that's good, and in the summer a fan will fix/ help with that.

sorry for the hijack! I should probably start a thread on it.... so here it is

____________________________________________________________

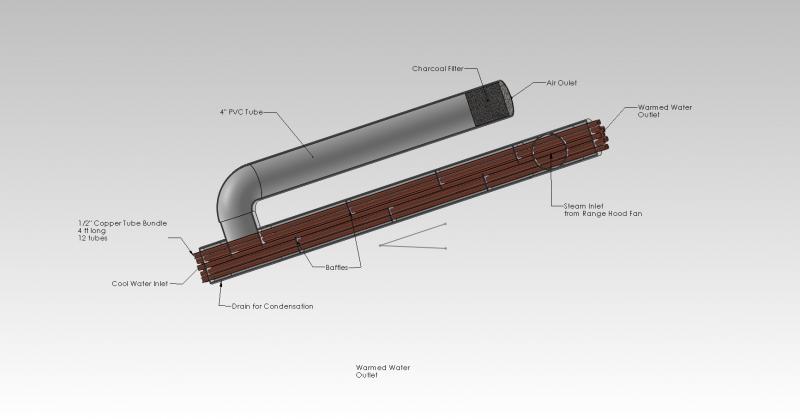

My plan: have a column with a copper coil in it the the pond pump pumps up to, then at the end of the coil spray the cooling water out into the steam flow. the condensed steam and the spray water falls back down into the bucket, like the commercial condensers the steam will be drawn in the top from the cool air pulling down and out the bottom.

the only question I am unsure of is how much cooling water is needed, and if i will be able to generate enough airflow.

Quote from Kal:

For home use I don't see this really working because:

- You'd need to run water through it during the entire boil (very wasteful).

- Nothing is 100% efficient so you'd still get *some* humidity in the room which will build up. How much, I don't know.

- Heat: None of the heat escapes the room so the room would likely get very warm over time.

I'm still curious to hear about experiences with a steam condenser however. It's an interesting idea.

Kal

end quote

My plan will just get most of the steam, in the summer its not a big deal I'll just leave a window open and in the winter a little humidity will be good!

for running water my plan was to recycle water from a large bucket with a pond pump.

with my system yes heat would build up and again in the winter that's good, and in the summer a fan will fix/ help with that.

sorry for the hijack! I should probably start a thread on it.... so here it is

____________________________________________________________

My plan: have a column with a copper coil in it the the pond pump pumps up to, then at the end of the coil spray the cooling water out into the steam flow. the condensed steam and the spray water falls back down into the bucket, like the commercial condensers the steam will be drawn in the top from the cool air pulling down and out the bottom.

the only question I am unsure of is how much cooling water is needed, and if i will be able to generate enough airflow.