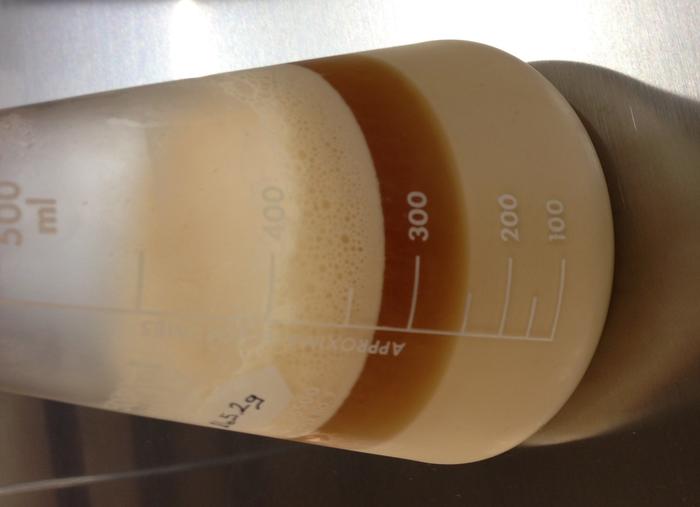

Despite the simplicity of the grain bill and how easily available the adjuncts are to get, this is a hard beer to brew correctly. I was lucky enough to hit just under the target numbers on my second attempt but the jury is still out on the final product. It's currently aging and has been sitting 3 months.

I paid super careful attention to detail but I can't stress the importance of the yeast quantity, viability, and quality. You definitely want to make at least a 2L starter. I pushed the OG in my last starter up to 1.060. I read somewhere that it helps yeast prepare to ferment HG beers with less stress. No idea how valid the info is but my fermentation went from 1.089 to 1.012 in a total of about three weeks without having to bother with anything.

I paid super careful attention to detail but I can't stress the importance of the yeast quantity, viability, and quality. You definitely want to make at least a 2L starter. I pushed the OG in my last starter up to 1.060. I read somewhere that it helps yeast prepare to ferment HG beers with less stress. No idea how valid the info is but my fermentation went from 1.089 to 1.012 in a total of about three weeks without having to bother with anything.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)