I have been wondering about strikewater volume. I have brewed off/on for 30+ years, but more seriously and regularly in the past half dozen when I switched to all-grain. I have followed a guide I found somewhere that suggests using 1.5 quarts water/ lb grain for mashing. Typically, I need a greater amount of sparge water than strikewater if I follow this guide.

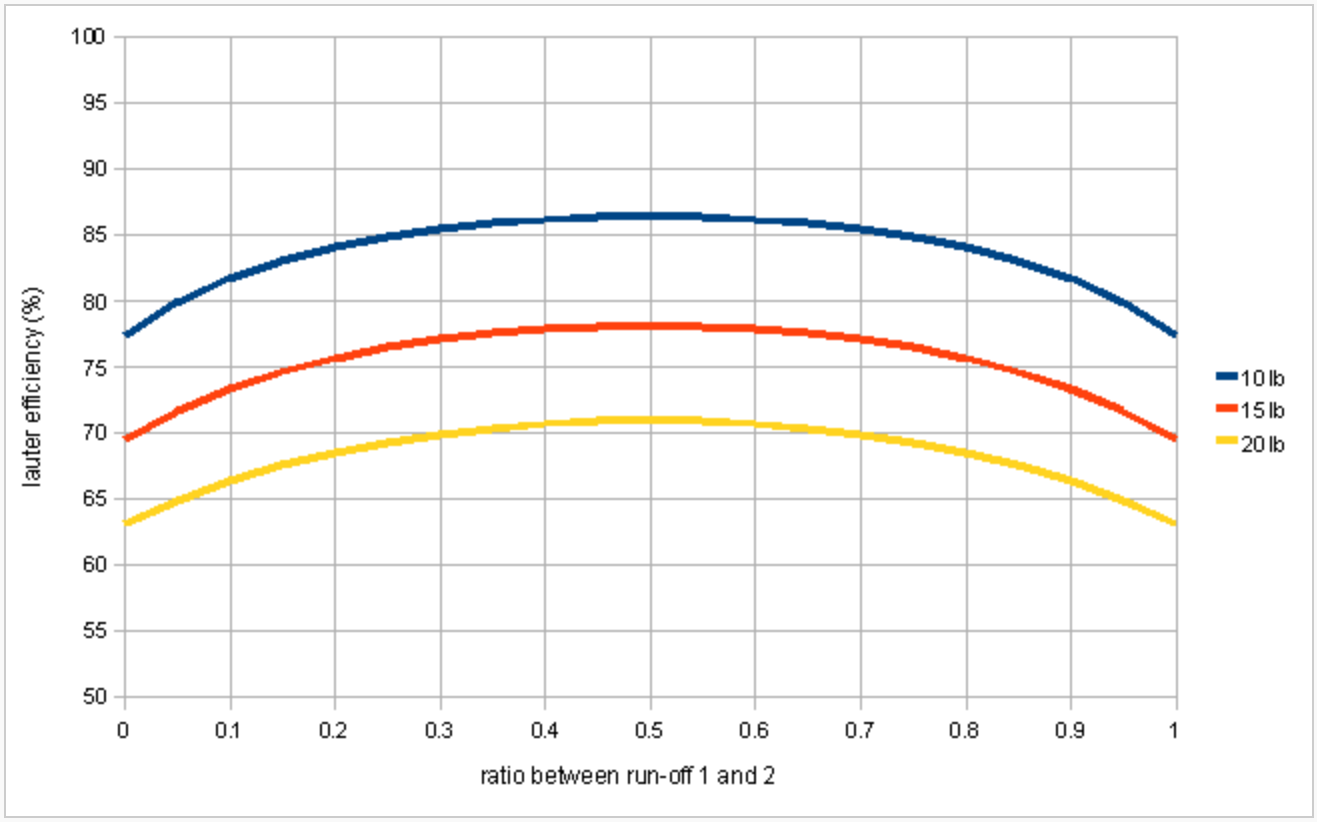

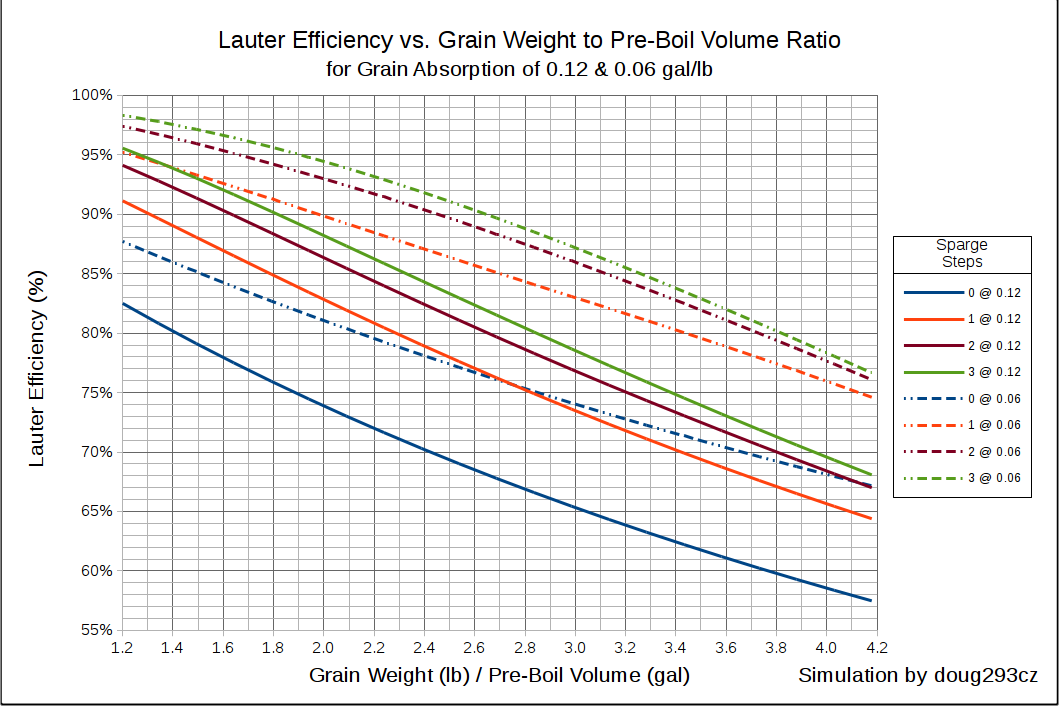

My question is this; would it not induce a higher sugar extraction with a greater volume of strikewater? It’s been decades since I took any chemistry/physics, but I recall something about movement from higher concentrations to lower and the greater the flow with increased gradient between the two. My thoughts are with a larger volume of strikewater, a steeper gradient is maintained longer that would promote higher sugar extraction.

Also, I am thinking that a sparge isn’t going to get you anything that wasn’t already extracted in the mash.

I confess that I have been going a little higher on the strikewater, and less on the sparge and have been getting higher than expected OG.

Is there something I am missing or neglecting that that would cause you to recommend that I reconsider my thoughts here?

Thanks!

My question is this; would it not induce a higher sugar extraction with a greater volume of strikewater? It’s been decades since I took any chemistry/physics, but I recall something about movement from higher concentrations to lower and the greater the flow with increased gradient between the two. My thoughts are with a larger volume of strikewater, a steeper gradient is maintained longer that would promote higher sugar extraction.

Also, I am thinking that a sparge isn’t going to get you anything that wasn’t already extracted in the mash.

I confess that I have been going a little higher on the strikewater, and less on the sparge and have been getting higher than expected OG.

Is there something I am missing or neglecting that that would cause you to recommend that I reconsider my thoughts here?

Thanks!

Last edited: