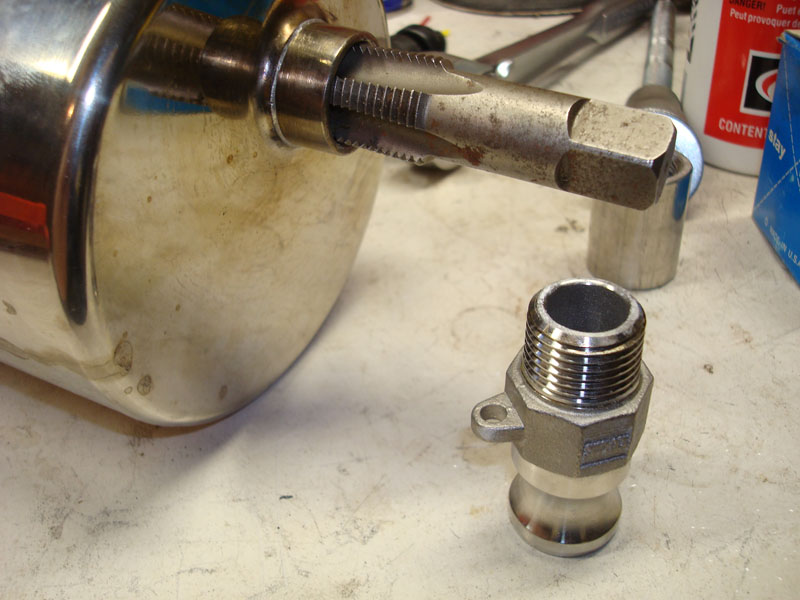

I'd like to add my bit to this otherwise most excellent thread. I just did my first dimple solder today. I decided to start with the grant because it is the least expensive vessel should things go wrong. The grant needs a bottom drain with a Camlock male. I will be installing a 1/2" half coupling. Here I have cut a hole with a 1/2" conduit punch (7/8" dia) and pulled a dimple with the tool set up as shown. I use a 1/2" bolt so a 1-1/16" socket for 1/2" square drive makes a great self-centering receiver. The remaining pieces on the bolt are just spacers for the long bolt. It is so long because I hope to later pull dimples and pull in couplings in one step, like Green Monti. Notice the piece of 1/2" copper pipe with masking tape on top of the grant.

After having pulled the expansion piece partially through, i reassembled the tool to pull the half coupling through. The piece of 1/2" copper pipe with masking tape is a snug fit inside the coupling which centers it on the bolt. Parts go on the bolt from left to right.

I put the nut in a vice which made it a lot easier to work the wrench with both hands.

The joint has flux and a solder ring is in place, almost ready for heat.

Before I put in the solder ring I filled the dimple with flux. It works like a spirit level so I can modify the mounting of the grant until it is plumb.

After applying heat with a MAPP gas torch. The solder has flowed through the joint and a bead shows up around the coupling. This alone verifies that the joint is sound and leak free. The inside of the joint is now mostly an esthetics issue, which is still worth doing right. By the way, notice the buildup of hardened flux in the threads.

Here's the stuff I used; Stay-Clean liquid flux applied with an acid brush, and Stay-Brite #8 solder.

The flux in the threads was hard to get out with just flux on a rag. I eventually used a 1/2" NPT tap to chase the threads out; the flux had turned to almost glass in there. The tap pulled out crunchy flakes.

Here's what the inside joint looked like after cleaning with flux, then soap and water. There is more solder than I would have liked. I think next time I'll use 75% of a ring and cut it in half to spread it around a little. Also there are stains remaining which do not look so hot. I tried to remove them with a green scrubby pad. It started to remove the stains but it scratched the metal surface so I stopped.

The solution to the flux stains turned out to be Bar Keepers Friend on a wet paper towel. I had an unopened can sitting around since I read rave reviews about BKF here on HBT. It did not let me down, I am a fan too now. The scratches you see are from the green scrubby. There are some faint marks left from the flux which I believe are etched into the surface so they will not come out. Removing the flux sooner may reduce these etchings.

That's it for me. Thanks all who have contributed to our common knowledge.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)