First attempt. I did not let the flux sit very long on the fittings before soldering it with a propane torch.

I used regular lead free plumbing solder.

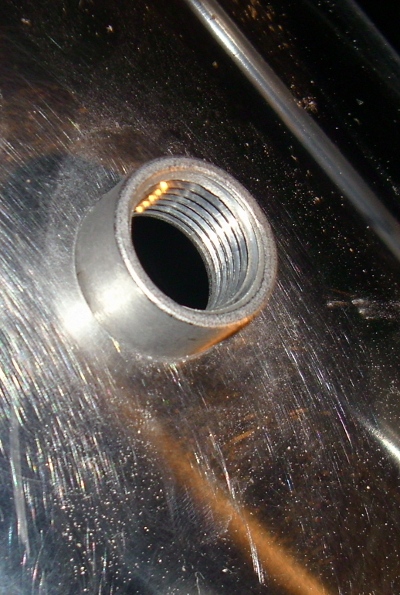

I'm quite surprised how well it worked. I think I overheated the fitting. Obviously there is way too much solder on there. You can see where the flux had not wetted the steel. The solder kinda bunched up around it.

NOTE: this is a damaged nipple. I don't sell ugly stuff like that!

I used regular lead free plumbing solder.

I'm quite surprised how well it worked. I think I overheated the fitting. Obviously there is way too much solder on there. You can see where the flux had not wetted the steel. The solder kinda bunched up around it.

NOTE: this is a damaged nipple. I don't sell ugly stuff like that!