Sawdustguy

Well-Known Member

Very, very nice! What prompted you to try all this?

Very, very nice! What prompted you to try all this?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

What would you think about using a 45% or 56% silver solder rod with the flux on the rod?

I know it's more expensive than the plumbers lead free, but in your opinion would you get a cleaner joint with less solder fill? Not to mention that high content silver solder is much better with dissimilar metals. Also with the flux core the joint would only need to be cleaned set and then heated in preperation for the solder.

Ideas, opinions, Corrections?

http://www.airgas.com/browse/product.aspx?Msg=RecID&recIds=144145&WT.svl=144145

But what would you think about using this instead of the 56% rod you posted and the Stay-Silv flux?

It's 56% Silver with a flux coating? I've used the 45% with flux coating to solder copper to carbon steel and it worked and flowed so easily.

I've been absent from the forums for a while, so here's my "stupid" question. Would it be worthwhile to solder a stainless coupler onto an aluminum pot? Or is that a bad idea? Thanks.

im in the process of making a electric brew pot with a pid controller.My plan was to buy a stainless steal nuts and take it to a weld shop and have it welded for the heating element and the thermocouple. Would this silver solder work for me?Could I drill a hole a hole a little biger than the the diameter of the threads and braise the inside and outside of the tank. Then thread the heating element and thermocouple well into the nuts . I want to be able to replace the element if it ever goes bad?? Right? Thanks for the help!

im in the process of making a electric brew pot with a pid controller.My plan was to buy a stainless steal nuts and take it to a weld shop and have it welded for the heating element and the thermocouple. Would this silver solder work for me?Could I drill a hole a hole a little biger than the the diameter of the threads and braise the inside and outside of the tank. Then thread the heating element and thermocouple well into the nuts . I want to be able to replace the element if it ever goes bad?? Right? Thanks for the help!

How well would the Mapp gas work with the silver solder?

This is awesome! I've sweated copper with decent results, but I think I overheated the joint because I got discoloration, charring, etc.

I assume SS is the same as copper; you're indirectly heating the joint and just lightly touching solder to the point you want to join, right? Swagman, how would you use an iron (clothes iron, right?) to do this...just turn the steam off, crank it on high, and maintain contact with the fitting?

150W soldering iron...

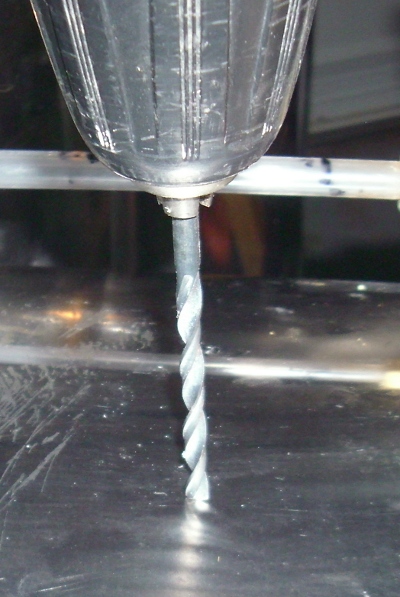

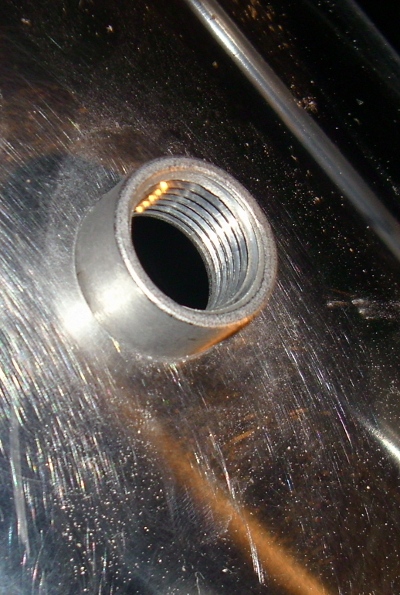

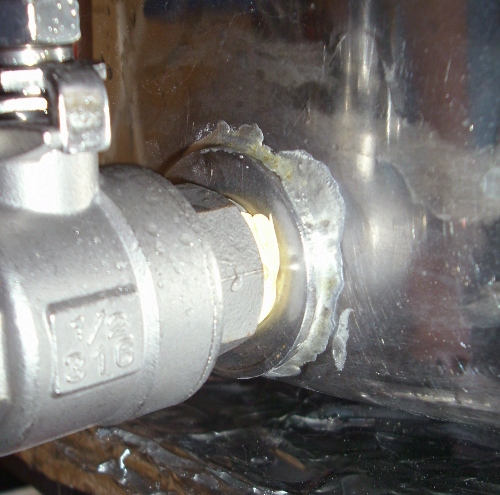

So I bought a hole saw just a bit too big for mounting my element in my SS kettle. So I took the nut from bargainfittings with me to Home Depot today and bought the right sized one. Got home and....

PUT THE WRONG ONE IN MY BIT and drilled the hole too big ANYWAY!

So I really had not choice but trying the soldering. I soldered it up, and...

HAD A LEAK (not unexpected) redid that edge of the nut.

NO LEAKS!

YAY thank you for this thread

Glad you could save the install. Can you post some pictures?