There is another benefit to the recirculation arrangement that Bobby describes in the OP, and it relates to mash efficiency (specifically lauter efficiency.)

In systems with fully, or partially, solid wall grain baskets or malt pipes, the liquid between the pipe wall and the vessel wall is isolated from the grain during the mash. Since recirc into the top of the malt pipe only does not move this liquid, it remains as very dilute wort. And the most concentrated (highest SG) wort will be inside and underneath the malt pipe. When you lift the malt pipe to drain the wort (lauter) some of the wort will be retained in the grain due to absorption, and this absorbed wort will be the most concentrated wort in the system.

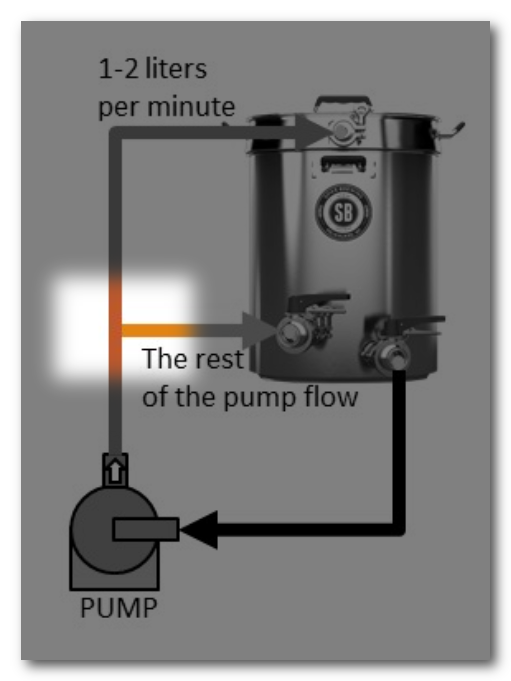

If the recirc also mixes up the wort between the pipe and vessel wall, this wort will become more concentrated, and the wort in the malt pipe will be lower concentration than if gap wort mixing had not occurred. Now when you lift the pipe, the absorbed wort will be lower in concentration than for the case of unmixed wort.

The higher the sugar concentration of the absorbed wort, the more sugar gets left behind in the grains, and the lower the lauter efficiency.

This also carries thru if you do a sparge. For any given sparge process and volume, the higher the sugar concentration in the grain bed at the beginning, the higher the sugar concentration will be in the grain bed after sparging. For example, if yourer sparge removes 60% of the sugar absorbed after the initial run off (a typical number for batch sparging), and you start with 6 lbs of sugar in the absorbed wort, then after sparging the grain still contains 6 * (1 - 0.60) = 2.4 lb of sugar. If on the other hand you homogenize the wort better throughout your total volume, and only have 4 lb of sugar in the absorbed wort, then after sparging you will only have 1.6 lb of sugar left in the grain bed.

How big an issue this might be will depend on what fraction of the total wort volume is held between the malt pipe and the vessel wall, which will depend on the specific geometry of your system.

Brew on

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)