SOBrewing

Member

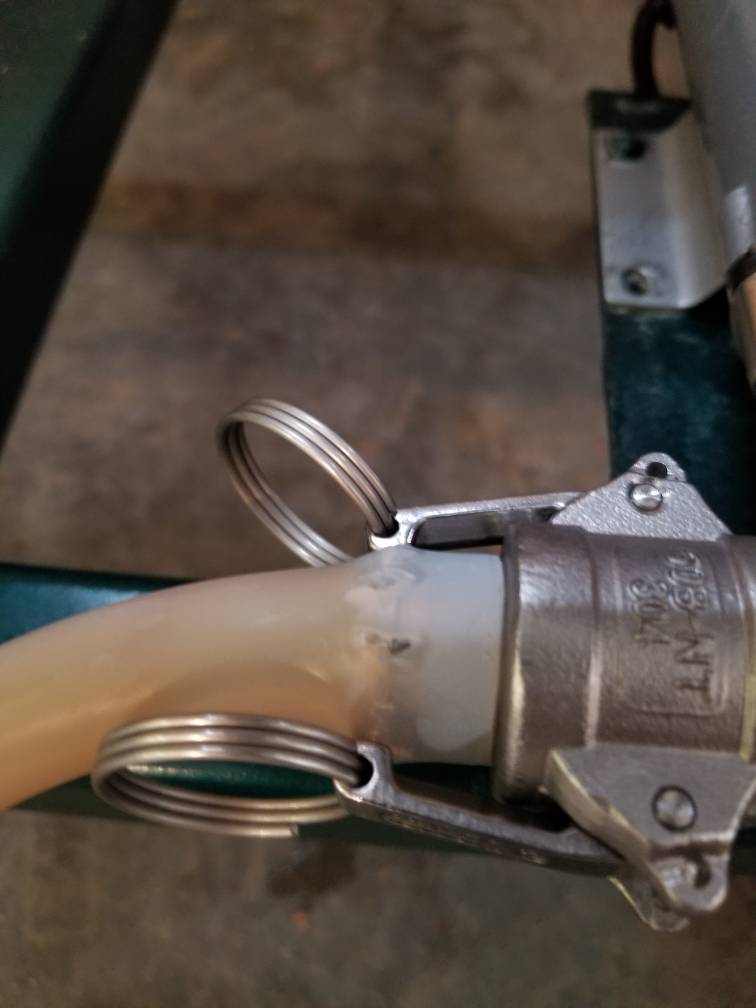

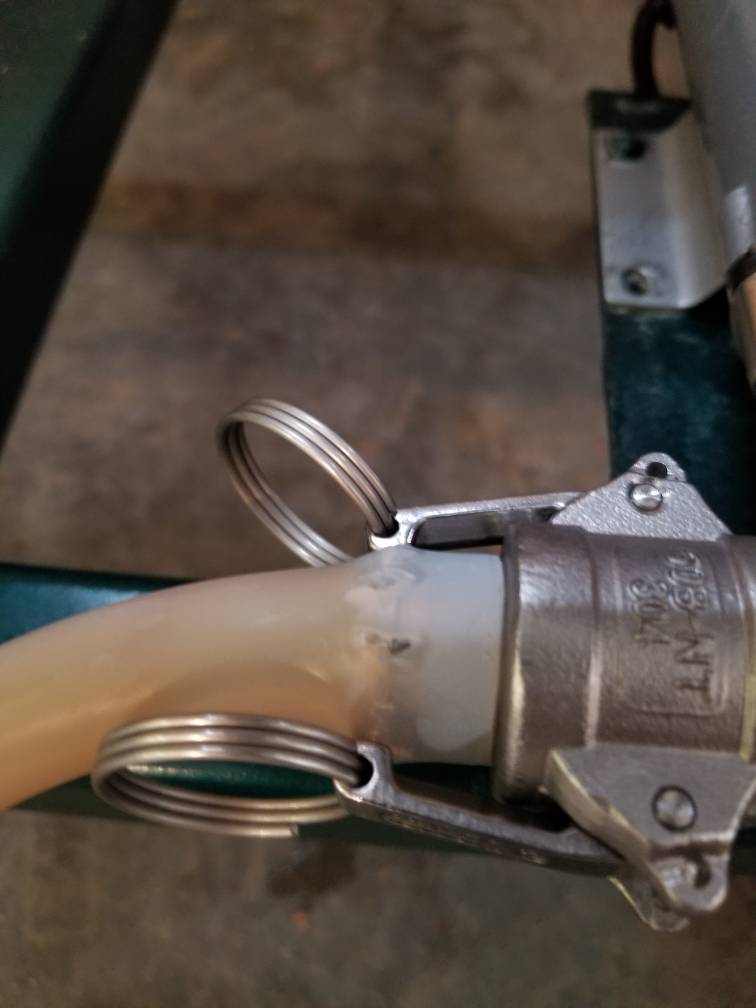

So I built my new stand a few months back and everything had been great until today. I got to looking at the silicone hoses and they are all trashed with only about 6 batches ran on them. At 2.65 a foot this is ridiculous and I can't find anybody else having the same issues so I am wondering what I am doing wrong. The cracking is on the kettle side AND the pump side so it's not flame heat like I had initially thought. After brew day they get hot water ran through them then soaked in a bucket of starsan for a couple hours. Any ideas?