You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show us your sculpture or brew rig

- Thread starter Onescalerguy

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

PaulHilgeman

Well-Known Member

- Joined

- Mar 14, 2008

- Messages

- 270

- Reaction score

- 7

After 2 weeks of late nights, I am ready for my rig's inaugural brew this Sunday:

See the build thread over here:

https://www.homebrewtalk.com/f51/80-20-brew-stand-212840/

See the build thread over here:

https://www.homebrewtalk.com/f51/80-20-brew-stand-212840/

r8rphan

Well-Known Member

You're using a tankless water heater? I was wondering if anyone had tried that yet...

Mine only goes up to 160... So I thought maybe that was the reason I had not seen any incorporated into a brew set up...

Or do you heat it more after it goes through the water heater?

I was thinking about getting a 110v point of use instahot... so that I could use water tight out of the hose bib and not wait forever for the burner to heat a keggle full of water from near freezing.. But I'm gonna move my rig to my deck once I am finished screening it in this spring... at which time I can just extend hot and cold water from the kitchen via freeze proof Hose Bibs... So I'll just hoof hat water from the kitchen in buckets for three or four months until I make the move..

But anyways... Sweet looking set up.. Looks like you put a lot of thought and work into it...

Mine only goes up to 160... So I thought maybe that was the reason I had not seen any incorporated into a brew set up...

Or do you heat it more after it goes through the water heater?

I was thinking about getting a 110v point of use instahot... so that I could use water tight out of the hose bib and not wait forever for the burner to heat a keggle full of water from near freezing.. But I'm gonna move my rig to my deck once I am finished screening it in this spring... at which time I can just extend hot and cold water from the kitchen via freeze proof Hose Bibs... So I'll just hoof hat water from the kitchen in buckets for three or four months until I make the move..

But anyways... Sweet looking set up.. Looks like you put a lot of thought and work into it...

PaulHilgeman

Well-Known Member

- Joined

- Mar 14, 2008

- Messages

- 270

- Reaction score

- 7

Thanks,

No, in order to use a tankless heater like that, you have to completely gut it, there are so many safety features built in that you could never get 170° strike and sparge water out of it.

For strike water, I fill the MT to my desired volume, then recirculate through the heat exchanger to get to my strike temp. This way, I don't have to run it WOT (imagine a flame shooting out of the chimney). For sparge water, I run it WOT in order to even get by at 0.5 gal / minute at 170°.

A 110v tankless heater would never be be able to produce water at much more than a trickle, you really need >5000W to heat water at an appreciable speed.

No, in order to use a tankless heater like that, you have to completely gut it, there are so many safety features built in that you could never get 170° strike and sparge water out of it.

For strike water, I fill the MT to my desired volume, then recirculate through the heat exchanger to get to my strike temp. This way, I don't have to run it WOT (imagine a flame shooting out of the chimney). For sparge water, I run it WOT in order to even get by at 0.5 gal / minute at 170°.

A 110v tankless heater would never be be able to produce water at much more than a trickle, you really need >5000W to heat water at an appreciable speed.

Obelix

Member

My first all Grain "Milk Crate and Slate Rig".

Current contraption. No more weather issues.

Got the idea from this thread. Now I'm moving to sanke's, so I have to renovate my setup again. I'm sure this thread will be a help.

r8rphan

Well-Known Member

Thanks,

No, in order to use a tankless heater like that, you have to completely gut it, there are so many safety features built in that you could never get 170° strike and sparge water out of it.

For strike water, I fill the MT to my desired volume, then recirculate through the heat exchanger to get to my strike temp. This way, I don't have to run it WOT (imagine a flame shooting out of the chimney). For sparge water, I run it WOT in order to even get by at 0.5 gal / minute at 170°.

What is "WOT"?

A 110v tankless heater would never be be able to produce water at much more than a trickle, you really need >5000W to heat water at an appreciable speed.

Yeah, I was just going to use it to pre heat water from the spigot (which is around 33-34 degrees) to something in the 80-110 degree mark as is was being dumped into the HLT for heating with the burner..

But that's a moot point now.. As I will just wait until I move the rig, where I can then draw hot water from the kitchen.. and for that I have the tankless control set to 145 degrees... which makes heating to 170 a piece of cake.......

So for now, I'm just gonna fill buckets of water in the kitchen and carry them up the ladder and dump them in... Until I get a sight glass installed, that's the only way I have to measure how much water goes in anyways..

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

PaulHilgeman

Well-Known Member

- Joined

- Mar 14, 2008

- Messages

- 270

- Reaction score

- 7

Wide Open Throttle (or in this case Needle Valve)

Gridlocked

Well-Known Member

The old - made from scraps that I had in the garage the night before my first all-grain run.

The new (work in progress):

The new (work in progress):

rrogerstwo

Active Member

Where did you get the console from?

Where did you get the console from?

If you want to get an answer, you should probably specify the person's name you are asking the question.

If you want to get an answer, you should probably specify the person's name you are asking the question.

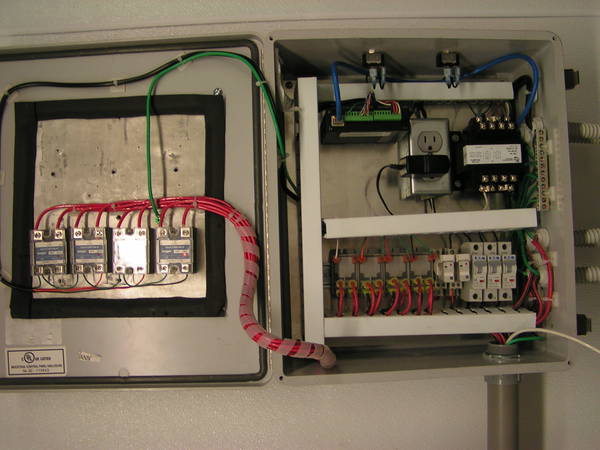

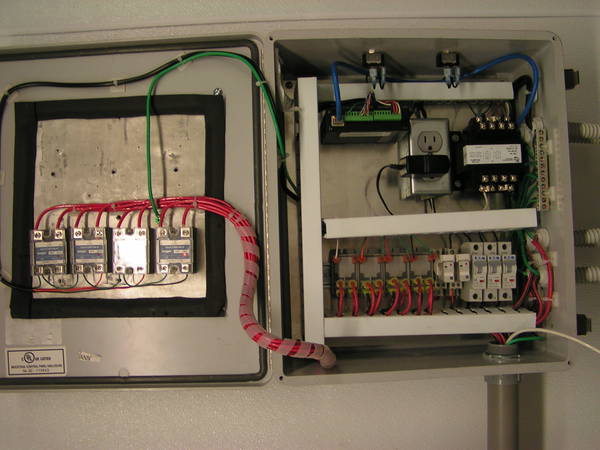

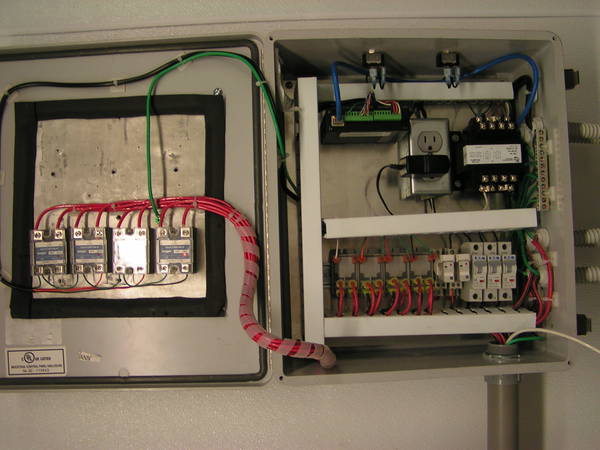

That's what I was going to say... but if it was referring to me, I built it. (Only reason I guess it was me.. was that I was the most recent posting one with a control box)

twardnw

Well-Known Member

rrogerstwo

Active Member

I have been looking for a control panel like the one you show in the photo, where did you find it?

MetallHed

Well-Known Member

I have been looking for a control panel like the one you show in the photo, where did you find it?

I'm fairly certain he built it, but he's only made two posts since joining in October.

You could look at Kal's write-up in the electric brewing section for a good, detailed plan for an awesome control panel.

- Joined

- Nov 6, 2007

- Messages

- 62,016

- Reaction score

- 6,923

All of these control panels you see are built by the users. There's no off the shelf panel like that. Systems vary to much. They're a little different for the most part to cater to the individual system. There are some turn key options like Sabco if you have the money though.

peterbrau

New Member

I designed and built the panel using parts from automationdirect.com. I have a parts list, schematic and layout diagram if you're interested. I sent an autocad output file to a machine shop that used CNC machine. The CNC takes the autocad file and cuts out the holes and engraves the labels right on the chasis I sent them.

barroomhero1234

Well-Known Member

This thread is awesome, if i am sad i can just look at these and realize I am not alone.

In the process of making my system will post soon!

Cheers!

In the process of making my system will post soon!

Cheers!

Budzu

Well-Known Member

Just received kettles from conical-fermenter.com. Its a 2 bbl HERMS, all electric, with 5500 watt heatsticks. Haven't finished adapting everything to tri-clamp, but its close to functional.

Gridlocked

Well-Known Member

Here is my new rig that I sincerely hope to have done in a week or two.

The one behind it is it's evil twin we made from start to where you see it on 2/5/11 (8:30a-11:30p)

The one behind it is it's evil twin we made from start to where you see it on 2/5/11 (8:30a-11:30p)

rrogerstwo

Active Member

Thanks for the information, this sends me in the right direction.

I designed and built the panel using parts from automationdirect.com. I have a parts list, schematic and layout diagram if you're interested. I sent an autocad output file to a machine shop that used CNC machine. The CNC takes the autocad file and cuts out the holes and engraves the labels right on the chasis I sent them.

rrogerstwo

Active Member

Thanks, I'll look that up.

I'm fairly certain he built it, but he's only made two posts since joining in October.

You could look at Kal's write-up in the electric brewing section for a good, detailed plan for an awesome control panel.

Just received kettles from conical-fermenter.com. Its a 2 bbl HERMS, all electric, with 5500 watt heatsticks. Haven't finished adapting everything to tri-clamp, but its close to functional.

That is beautiful... and in a perfect world what i'd like to get myself into eventually...please post more pics when you have it up and running...

klyph

Well-Known Member

Nice system Budzu! I love those heat sticks you built.

klyph

Well-Known Member

What do you miss about the direct fired mash tun? Adding insulation and a 2000w element will probably help if you're having trouble step mashing.

My efficiency went to crap...went from 85%+ to 60%. I have since added lower temp probe on MLT exit. I know insulation would help. I should just ditch the MLT keggle for a cooler. I just haven't adapted to my new setup. Not having to buy propane is so worth the growing pains.

klyph

Well-Known Member

How do you think the heating method affected your efficiency? I'm not seeing the corollary.

rrogerstwo

Active Member

Actually I was interested in the enclosure you used not the guts inside, sometimes I say one thing and mean another. But after surfing the web some more, I found a site that you can download their CAD and design what you want with the material you want, and they custom build it. The site is:http://www.emachineshop.com/

[quot...A/xxIxwTF1PBI/s800/IMG_2230.JPG[/IMG][/quote]

Blane

Active Member

Budzu said:Just received kettles from conical-fermenter.com. Its a 2 bbl HERMS, all electric, with 5500 watt heatsticks. Haven't finished adapting everything to tri-clamp, but its close to functional.

That's just beautiful......(sniff) (sniff). I just want to be alone for a little while now.

rroger, are those temp controlers or just digital displays?

Similar threads

- Replies

- 11

- Views

- 1K

- Replies

- 132

- Views

- 9K

- Replies

- 45

- Views

- 5K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)