I would think a horizontal tube with I/O pointed up would be best. If the tube is vertical, you'll always have a bubble at the base of the sensor. And if the sensor isn't submerged, you'll have problems as well.

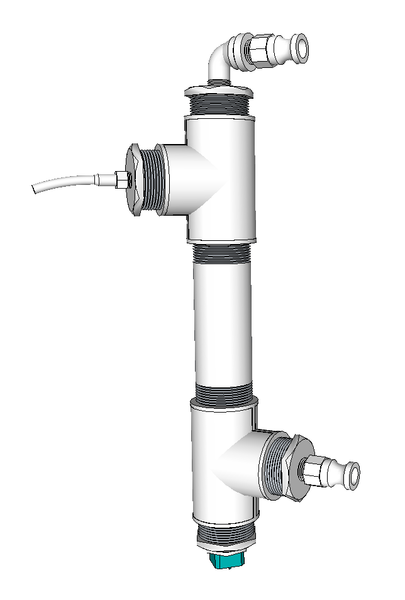

Depends on the configuration of the tube. If the outlet is on top then there will be no air bubble. This probe is mounted at upper left, it is always submerged.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)