daggers_nz

Well-Known Member

Unless one wants to harvest clean yeast, even fruit can go into a primary.

what about dry hops? never done it myself, always used a glass carboy but I'd be open to being convinced otherwise

Unless one wants to harvest clean yeast, even fruit can go into a primary.

what about dry hops? never done it myself, always used a glass carboy but I'd be open to being convinced otherwise

Sure you can dry hop in a primary, most effective after cold crashing, to first drop all the yeast out. Simply suspend the hops in a muslin bag with a small weight in it, like glass marbles or a spare stainless fitting. The key is, racking to another vessel can introduce unwanted bugs, so best to avoid the whole issue.

This was found in one of the beer bottles i gave to people. He states he opened poured his beer drank it and found it in the bottle after he had cleaned it. I made a stout with extract. What is it? Is this possible. I washed then sanitized in my dishwasher.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

True but I would come back up to 60 or 70 for the dry hop period. The aromas don't transfer as well in cold liquid. I frequently rack to keg, suspend muslin bag, keep at room temperature for 5 to 10 days, then just put into kegerator. I have left the dry hops in the keg for the entire serving period. Over several weeks to months and no grassy taste at all in fact the aroma is amazingly powerful.

This was found in one of the beer bottles i gave to people. He states he opened poured his beer drank it and found it in the bottle after he had cleaned it. I made a stout with extract. What is it? Is this possible. I washed then sanitized in my dishwasher.

Rauchbeer or Roachbeer?

Looks like a bug to me. However it's really small, given the size of the Q-tip it's on. Could have been stuck in one of the bottles. One more reason to always use a bottle brush when cleaning bottles. A dishwasher cannot rinse bottles out well because of the thin necks, like a jet bottle washer does.

Absolutely, the hop oils dissolve/diffuse much better in warmer beer than ice cold. The idea of cold crashing before dry hopping is to drop yeast out of suspension so it won't take precious hop oils with it when crashing later. Not sure if that's been proven, though. Lots of myths hanging around, someone said it or you read it somewhere, others repeat, and it becomes truth suddenly.

I prefer to dry hop in kegs too, same way you do, and leave the bag in there, hanging from a thin wire, until cleaning day. For those without kegs, using the fermentor is the only way.

I've been using a thin but pretty tightly woven muslin cloth (fabric store), made into bags (pouches), since the fine mesh nylon "hop bags" let too much pellet dust through, particularly when agitating to speed up the extraction process and you'd end up with a ton of suspended particulate that has a nasty bitter taste and doesn't settle quickly or well. The muslin fibers swell up a bit and form a great barrier for the solids but let the beer and aromatic oils through. Decent amount of agitation is needed though, IMO.

I hate this to be my first post but so far you have answered all my questions without me having to ask them myself. Thanks for sharing all your knowledge.

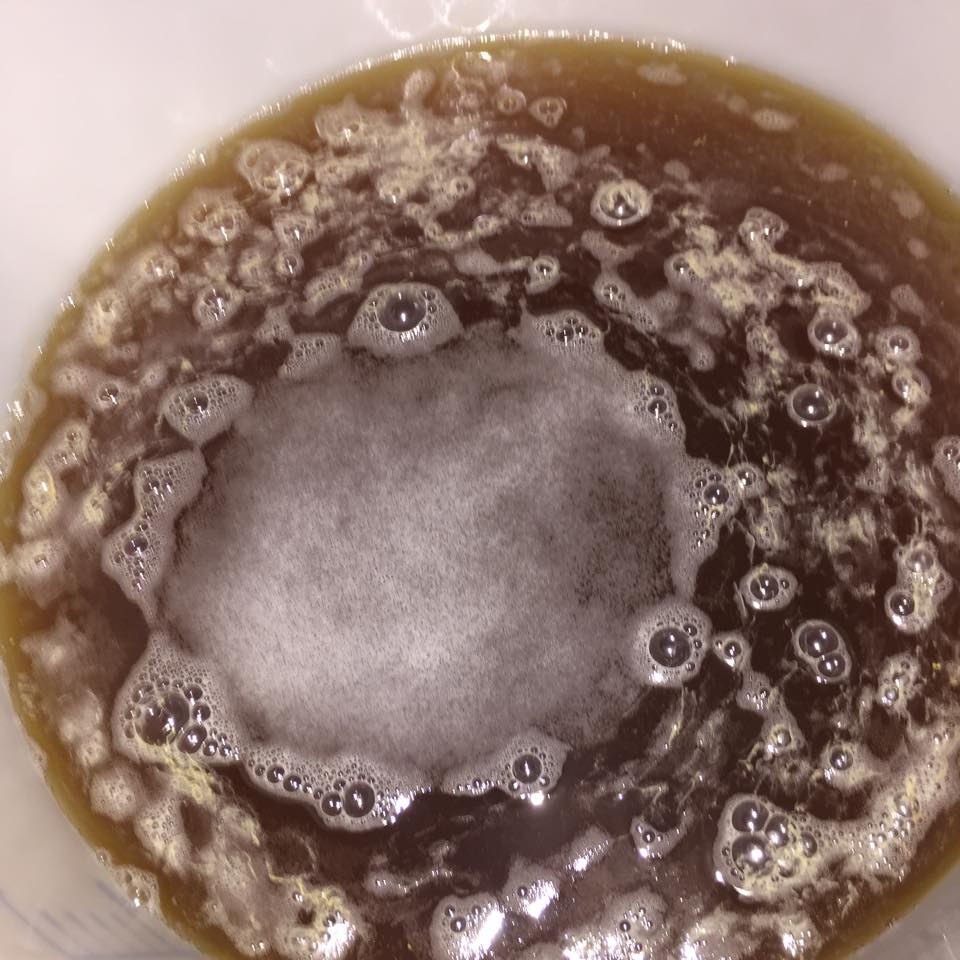

This is my 4th brew. It's supposed to be an APA and is 9 days into primary right now.

I took two readings so far and was about to dry hop it soon. Three days ago it was at 1.025 (from 1.050) and was very promising. no off smell or bad taste at all. The yeast build up on the bottom of my fermenter is also pretty impressive, more than i ever had before.

Today I taped a sample and took another reading (1.019) and suddenly it tasted quite sour. After peeking under the lid i noticed these white/dry looking dots on top of the krausen. What do you guys think? Probably lacto?

Well it's nothing compared to some of the furry beasts in this thread but it's just day 9 .. might still 'grow up'.

Any advice? Scoop it off? leave it? Ditch it?

Judging by the rest of this thread you'll probably tell me to keep it going, keg it and try it. am I right with that?

I usually cold crash after dry hopping for a couple days before bottling. This way all the hop particles fall out of suspension and I can bottle without transferring any of the hop particles. The hop aroma is still great in the bottles, but I have noticed that it fades very quickly.

I would be hesitant to cold crash BEFORE dry hopping..for me the point of cold crash is to drop everything out of suspension so it's easier/clearer when it goes into bottles.

But when agitating vigorously (shaking or rolling in a keg) enough fine hop dust makes it out of those and takes a long time to settle, even in a cold keezer. Then the first few pints (as many as 6) are undrinkable and wasted

???

Why would a little hop haze make a beer "undrinkable and wasted?" Some hop haze is actually to style for IPAs.

Are you actually dumping several glasses of IPA because they're TOO hoppy?

Exactly! Maybe been there yourself?Hop haze comes from the lupulins that give aroma, flavor & bittering. He's referring to the fine poofy stuff from hop pellets that get into the beer from too aggressively agitating it with the dry hop sacks in it.

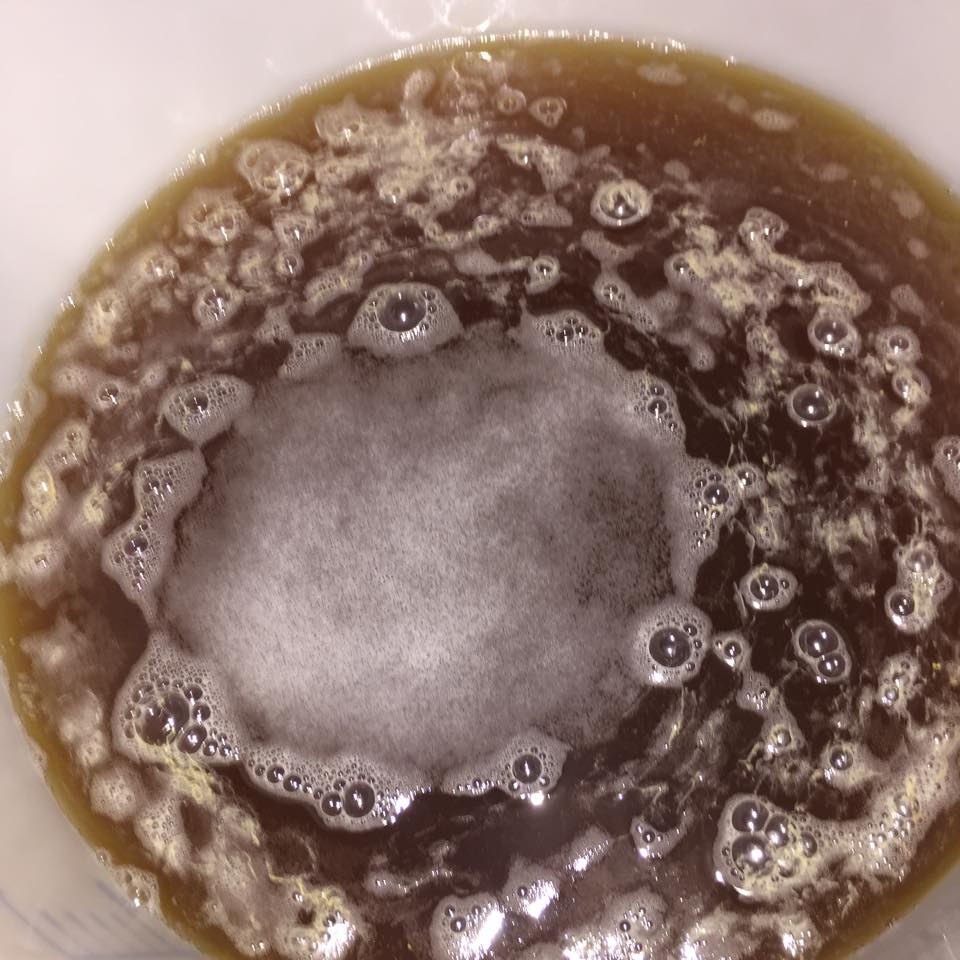

Seems like I've got my first infection ever on my hands.

This just as I was going to pitch brett into the secondary of this batch.

Is it possible to still pitch brett in this or should this just go straight in the drain?

It smells of overripe apples at the moment. It's primary fermented with WLP Champagne Yeast and has quite a bit of Nelson Sauvin in it so I don't think either of those things should contribute with that apple smell really. Transferred it to secondary a week ago and then it definitely did not have this smell.

Any ideas? Thanks!

Thanks for the replies everyone!

I'm fairly certain that the fermentation was off when I transferred it, but perhaps the yeast was roused and kicked off fermentation again or something, but I suspect this is infected.

I followed the same procedure that I usually do regarding sanitation, cleaning with PBW and desinfecting everything that is in contact with the wort/beer with Starsan, but of course that is not a guarantee.

I decided to pitch some brett in it and I will let it sit for a couple of months or so just to see what happens.