You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

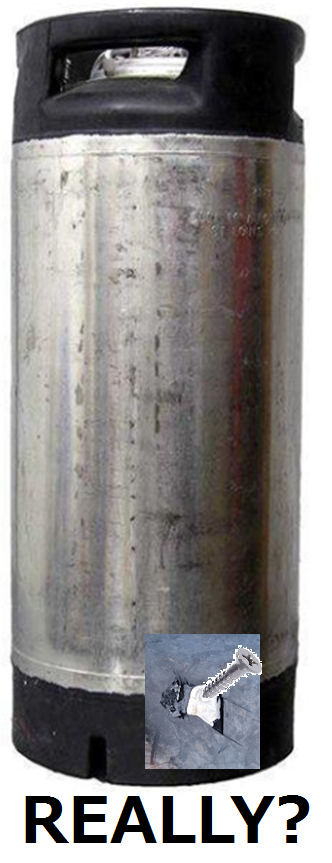

Pinhole in corny, can i silver solder it?

- Thread starter Beer666

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

bracconiere

Jolly Alcoholic - In Remembrance 2023

drill it out? use some sorta weldless tri-clamp plug for it?

The correct answer was given above: scrap the keg.

A pin hole at the bottom of a corny doesn't just magically appear, and my bet is the entire metal bottom was compromised by whatever that keg was used to hold. So "fixing" one hole might be a metaphorical finger in the dike...

Cheers!

A pin hole at the bottom of a corny doesn't just magically appear, and my bet is the entire metal bottom was compromised by whatever that keg was used to hold. So "fixing" one hole might be a metaphorical finger in the dike...

Cheers!

A few moments after I posted that I thought to myself that there is a Tinless Solder.... also need to watch and make sure there is no lead in the solder...Thanks for your reply.Electronics and plumbing capillary solder is either tin/silver or tin/antimony. Silver solder is silver/copper/zinc and does not contain tin so that it has a much higher melting point than the other kinds.

bracconiere

Jolly Alcoholic - In Remembrance 2023

but beer666 wanted satanic ideas to save it!

i just was thinking, i swear i've seen keg conversion things, where the whole bottom of the keg is removable? for like a fermenter or something? maybe something like that? lol

i just was thinking, i swear i've seen keg conversion things, where the whole bottom of the keg is removable? for like a fermenter or something? maybe something like that? lol

apache_brew

Well-Known Member

I'd cut the top off and weld it onto a 1/2 bbl sanke, but that's just because I have a TIG torch.but beer666 wanted satanic ideas to save it!

i just was thinking, i swear i've seen keg conversion things, where the whole bottom of the keg is removable? for like a fermenter or something? maybe something like that? lol

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

Down_Home

Member

- Joined

- Feb 26, 2017

- Messages

- 10

- Reaction score

- 10

A couple of folks up the thread suggested a screw in the hole. Take their advice. Use a fine-thread stainless steel screw with a silicone washer (or a dab of silicone bathtub caulk). This is a cheap fix and will stand up to the pressure for a goodly time. If/when it starts to slowly leak, repeat the procedure.

Seriously? People - it is an old used up keg. Let it go already. Is this where the hobby is heading? Best practices please....!

If one of my kegs had a pinhole I would certainly try to solder it. What's 30 PSI amount to on a tiny hole with a diameter of 1/64"? I might only use it for storing StarSan to purge other kegs, etc, but that tiny hole sees very little pressure in a homebrew situation. If the soldering job turned out really well I certainly would put it back in beer service.

OTOH, the question about bleach damage is a good one, if that were the cause it's likely it will spring several more pinhole leaks. In that case I would strip it down and scrap it.

OTOH, the question about bleach damage is a good one, if that were the cause it's likely it will spring several more pinhole leaks. In that case I would strip it down and scrap it.

If one of my kegs had a pinhole I would certainly try to solder it. What's 30 PSI amount to on a tiny hole with a diameter of 1/64"? I might only use it for storing StarSan to purge other kegs, etc, but that tiny hole sees very little pressure in a homebrew situation. If the soldering job turned out really well I certainly would put it back in beer service.

OTOH, the question about bleach damage is a good one, if that were the cause it's likely it will spring several more pinhole leaks. In that case I would strip it down and scrap it.

If you leave 100% bleach in a keg for a few days, you will end up with a pinhole right at the exact spot shown in post #1. Then, when filled with beer, it will slowly leak into the rubber seal, and you end up with 5g of beer on the floor of your keezer. Then you scratch your head many times because you can't figure out how it's leaking until you you cut away the rubber. Ask me how I know

I agree that that the hole size means the solder or other fix won't likely fail. Minor correction to what was posted above: the hole will see the same pressure as the rest of the tank (i.e., 30 psi). But the force is less (force = psi*area).

Beer666

Well-Known Member

- Joined

- Apr 10, 2018

- Messages

- 596

- Reaction score

- 616

Really appreciate all the replies, great people on here. Had no idea about this subject as i have only soldered electronics. I hope people realise i would of removed more rubber before attempting any repair as i dont have any pyromaniac leanings.  For what its worth i tried to remove the whole base by boiling it in my HLT as i figured it might soften the glue but no such luck. It made very little difference. Seem to remember someone making a rocket stove from an old keg.

For what its worth i tried to remove the whole base by boiling it in my HLT as i figured it might soften the glue but no such luck. It made very little difference. Seem to remember someone making a rocket stove from an old keg.

If i can find a screw and it holds pressure i will save it for starsan. Guess its time to buy some new kegs, losing beer after all is heartbreaking.

If i can find a screw and it holds pressure i will save it for starsan. Guess its time to buy some new kegs, losing beer after all is heartbreaking.

JB Weld. one drop of each tube. mix well. drop the blob right on the pin hole from the inside and let it ooze through the pin hole as it spreads out and cures. That stuff is bullet proof. Once cured I wouldn't worry about it affecting your beer.

This is my thought too for future reference, certainly the easiest first attempt.

Seriously? People - it is an old used up keg. Let it go already. Is this where the hobby is heading? Best practices please....!

View attachment 720195

Why would you not attempt to help people that can't easily get supplies? Not everyone is in the US and can get them for dirt cheap. It's a hobby, not a brewery.

Beer666

Well-Known Member

- Joined

- Apr 10, 2018

- Messages

- 596

- Reaction score

- 616

Similar threads

- Replies

- 11

- Views

- 3K

- Replies

- 45

- Views

- 6K

- Replies

- 1

- Views

- 3K

- Replies

- 10

- Views

- 2K