thehopthief

Member

- Joined

- Jun 23, 2020

- Messages

- 17

- Reaction score

- 1

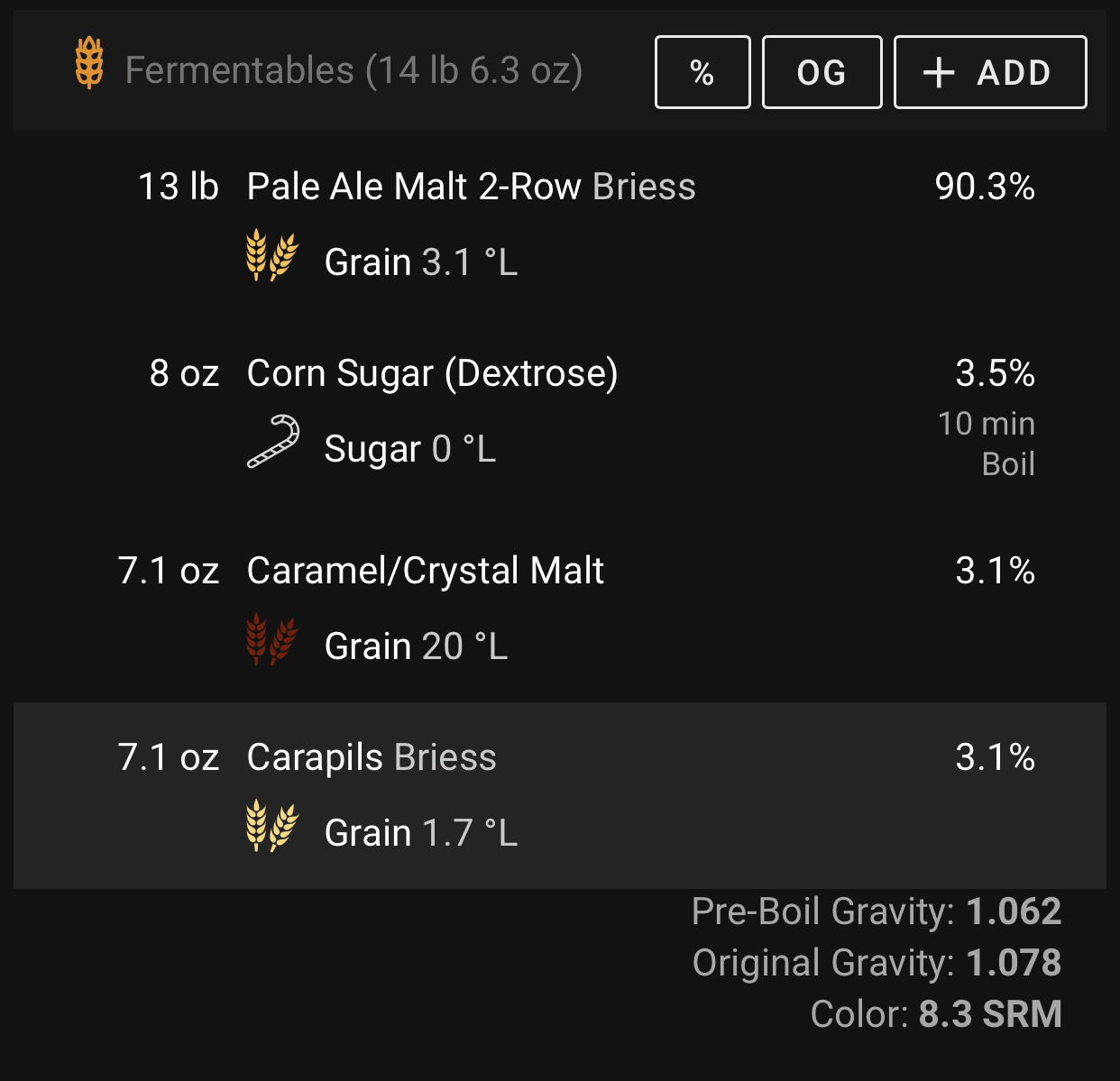

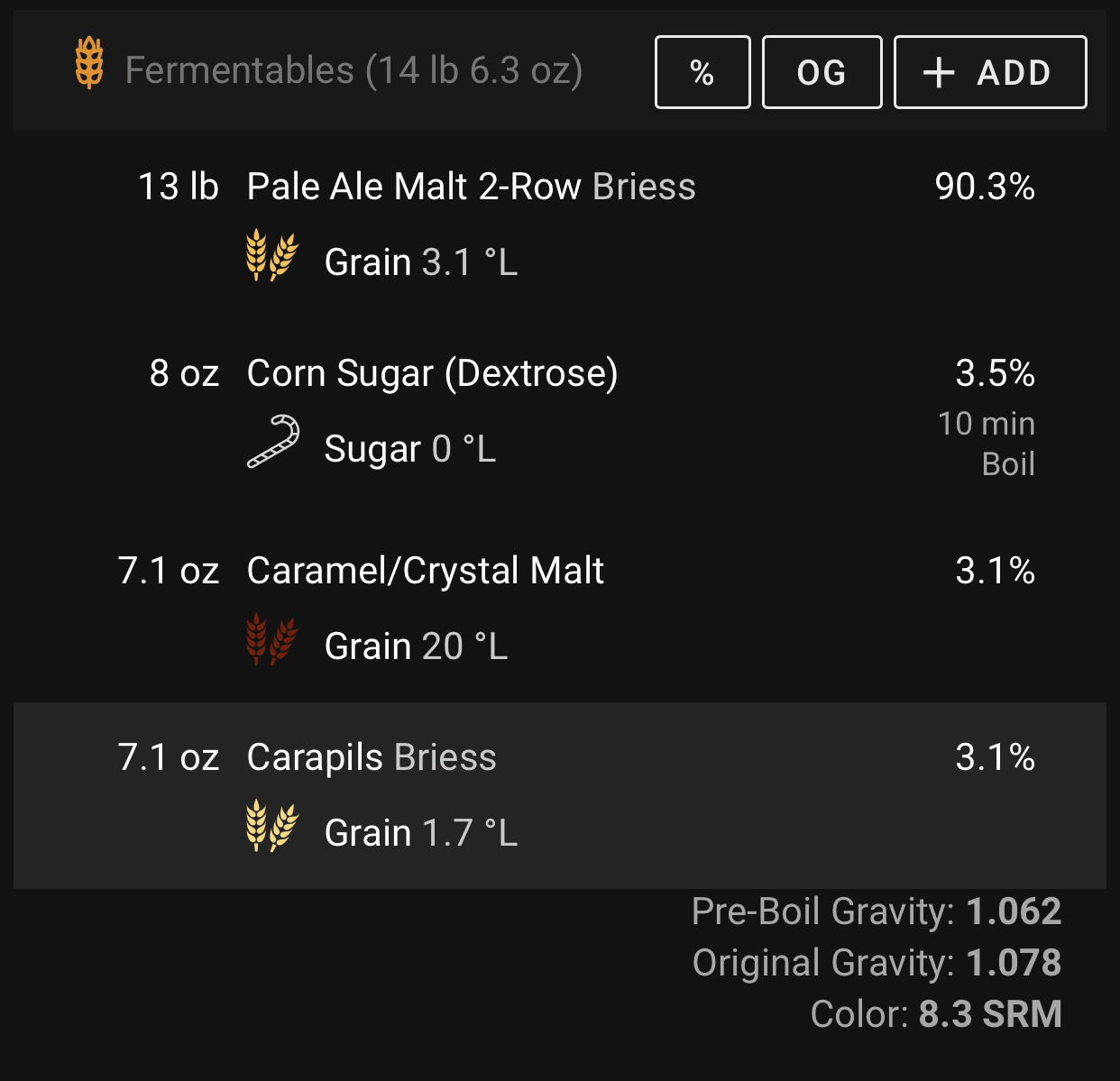

I recently brewed a double IPA with Amarillo, Citra and Mosaic hops. I was going for a very hop forward beer but with enough malt backbone to not be overwhelming. Unfortunately what I got was a very malt forward 9% beer with only a slight Mosaic aroma and trying to figure out why. Here's my grain bill. I ended up using some DME with 10 min left to bump the ABV as well.

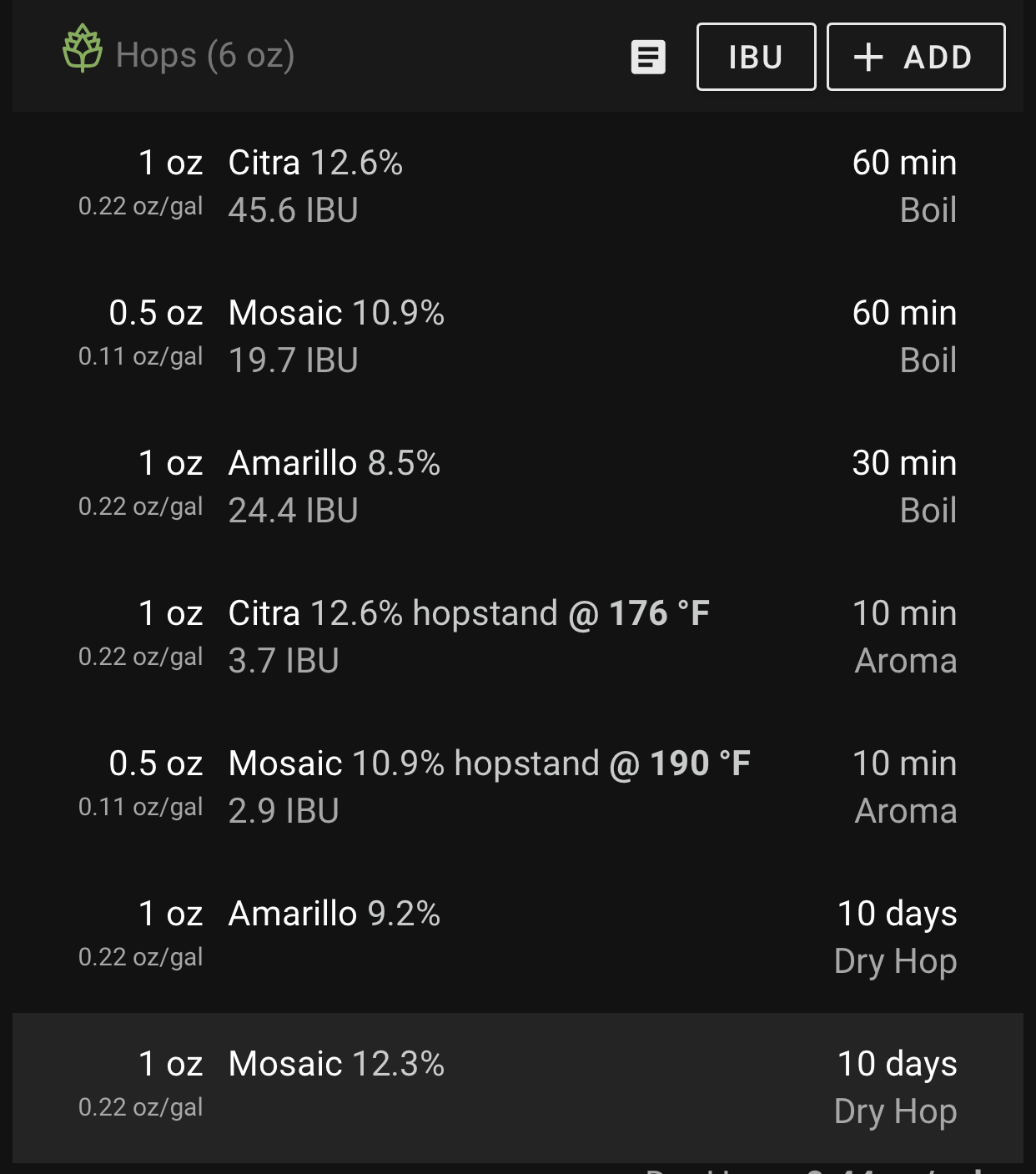

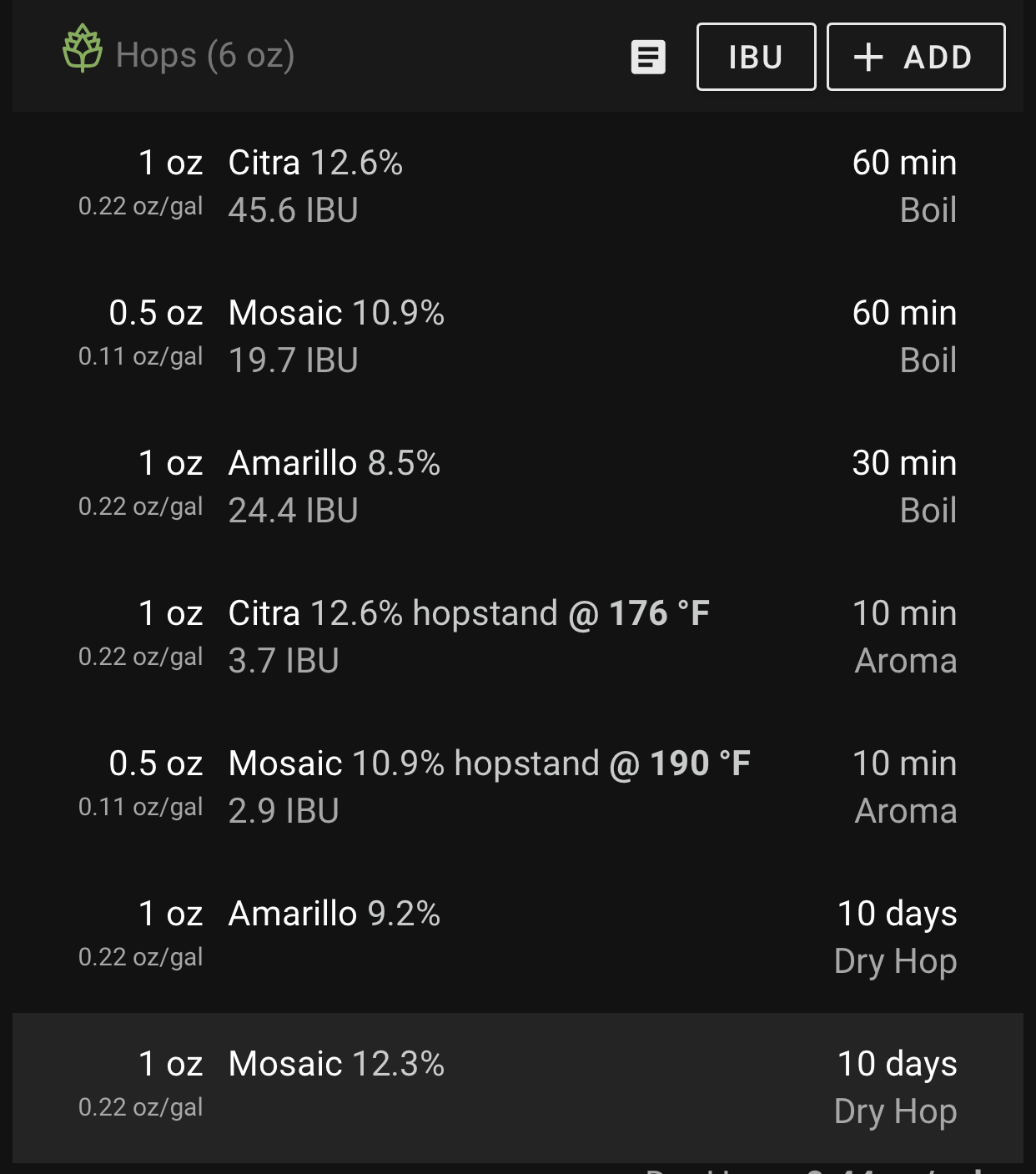

Here's the hop list

I fermented in primary for 10 days, moved to secondary and dry hopped for 10 days. Bottled on day 20 and it was carbonated 2 weeks later and today is 3 weeks and moving rest to fridge.

Mashed at 149 for 75 min using BIAB method.

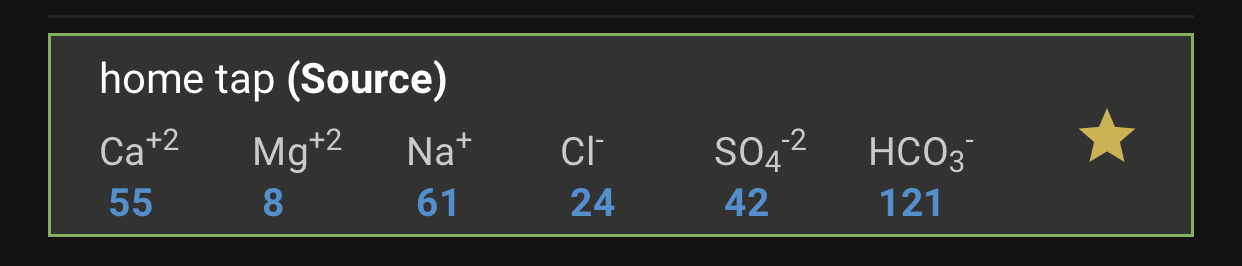

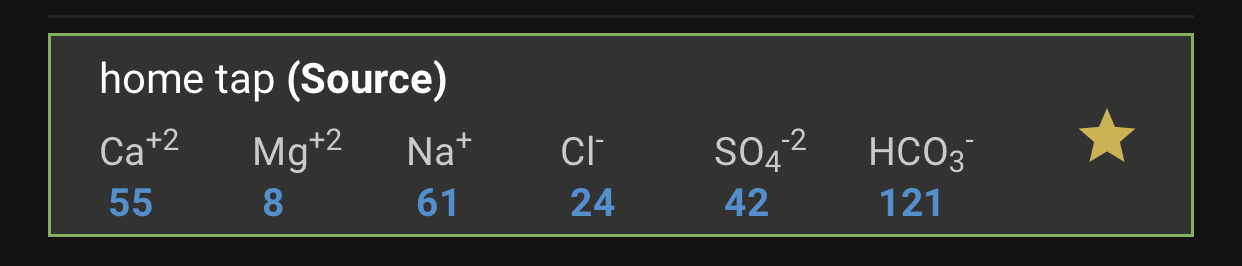

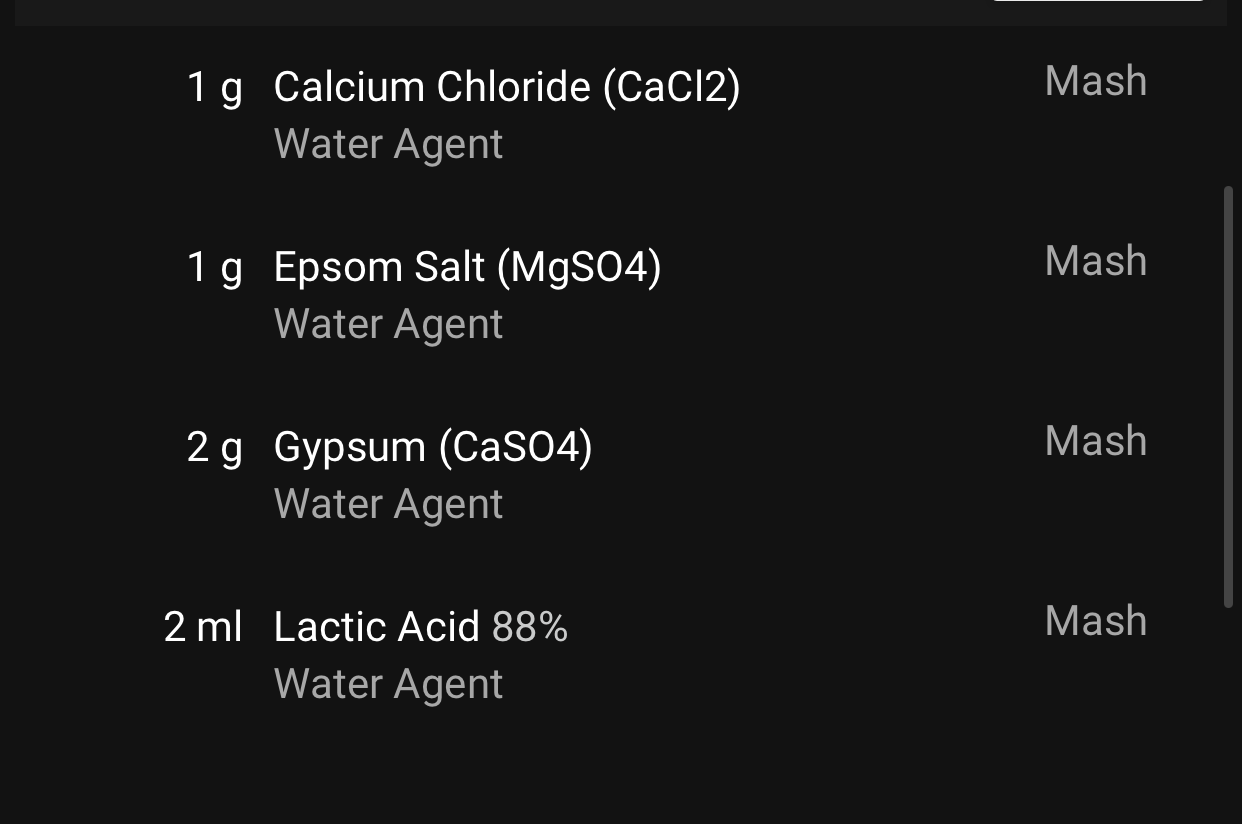

I'm thinking it has to do with my water profile

I think my sulfate to chloride should be higher for sure but this was my first attempt at all grain so I didn't modify the water. Any other thoughts?

Here's the hop list

I fermented in primary for 10 days, moved to secondary and dry hopped for 10 days. Bottled on day 20 and it was carbonated 2 weeks later and today is 3 weeks and moving rest to fridge.

Mashed at 149 for 75 min using BIAB method.

I'm thinking it has to do with my water profile

I think my sulfate to chloride should be higher for sure but this was my first attempt at all grain so I didn't modify the water. Any other thoughts?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)