You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Now What?!

- Thread starter bdogg171

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

What I need to do is roll it out down the street and see how much there really is, I honestly don’t remember.

I also got what is supposed to be 65 ft of 10/4, looks like it’s only rated for 25 amps though.

I also got what is supposed to be 65 ft of 10/4, looks like it’s only rated for 25 amps though.

2 gauge seems a bit large for brewery use. On the upside, now you use your arc welder in the neighbor's yard when helping him fix his trailer.

Last edited:

2 gauges seems a bit large for brewery use. On the upside, now you use your arc welder in the neighbor's yard when helping him fix his trailer.

Lol.

But doesn’t everyone say bigger is better?

Once i measure it out I may or may not keep some of it and trade the rest or something?

Joe17

Active Member

- Joined

- Nov 21, 2017

- Messages

- 29

- Reaction score

- 6

Lol.

But doesn’t everyone say bigger is better?

Once i measure it out I may or may not keep some of it and trade the rest or something?

Let me know. Cheers!

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$33.98

DYKWSWYX Heavy Duty Brewing Gloves (1 Pair) - 55CM Long Chemical Resistant Plastic Gloves for Beer & Wine Making, Cleaning, Homebrew Equipment Protection

wuhanshijiayangzhiyimaoyiyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

augiedoggy

Well-Known Member

10/4 awg is good for 30 amp and what most with 30a panels use for the power cord.. That would work fine for an electric biab panel but you want 6 awg for a power cord for a 50a panel... The 10/4 is kind of overkill for element power cable because you will only use 3 conductors and it wont work all that well being so large in diameter...

I would find an electrical contractor that will trade you for what you need...

I would find an electrical contractor that will trade you for what you need...

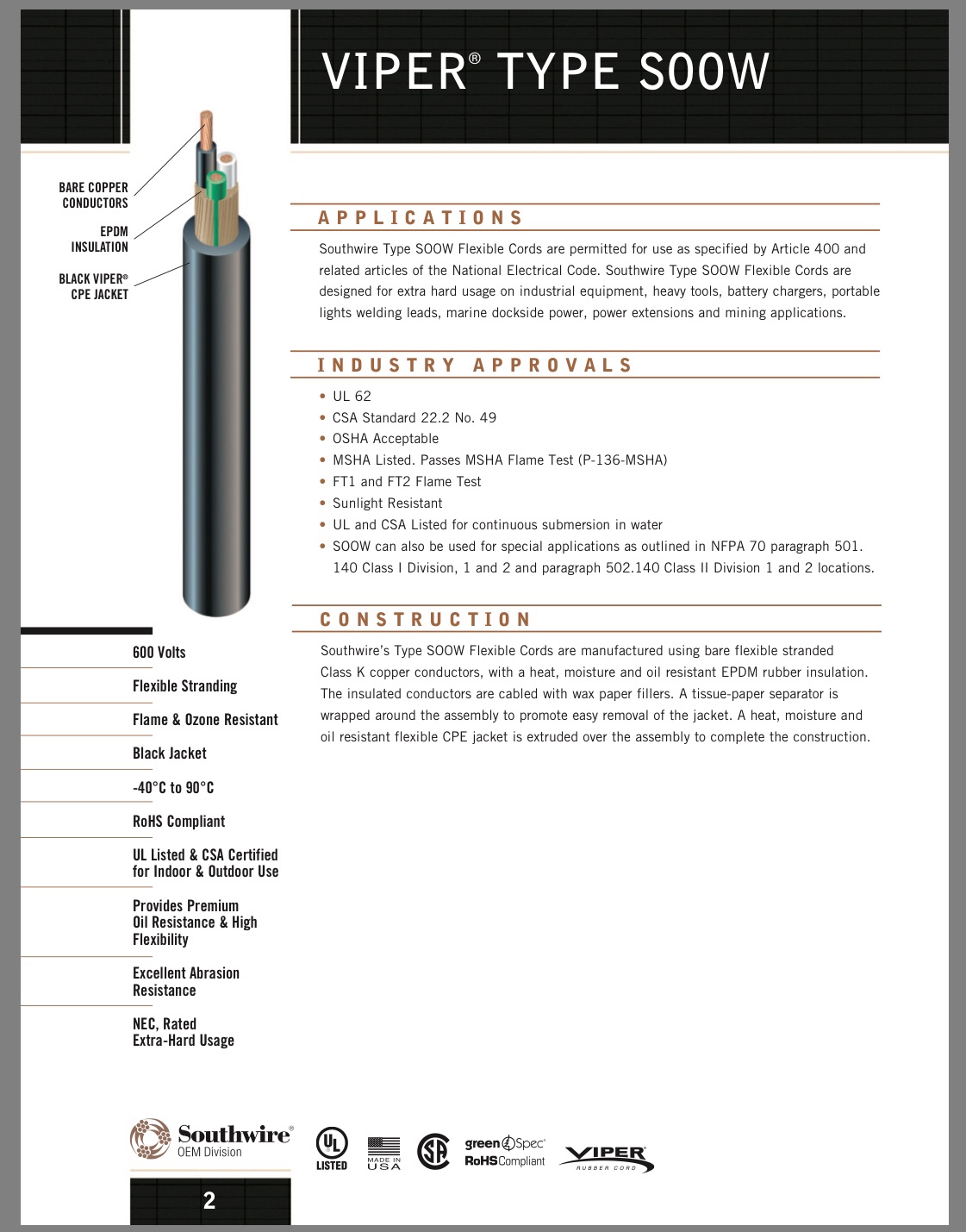

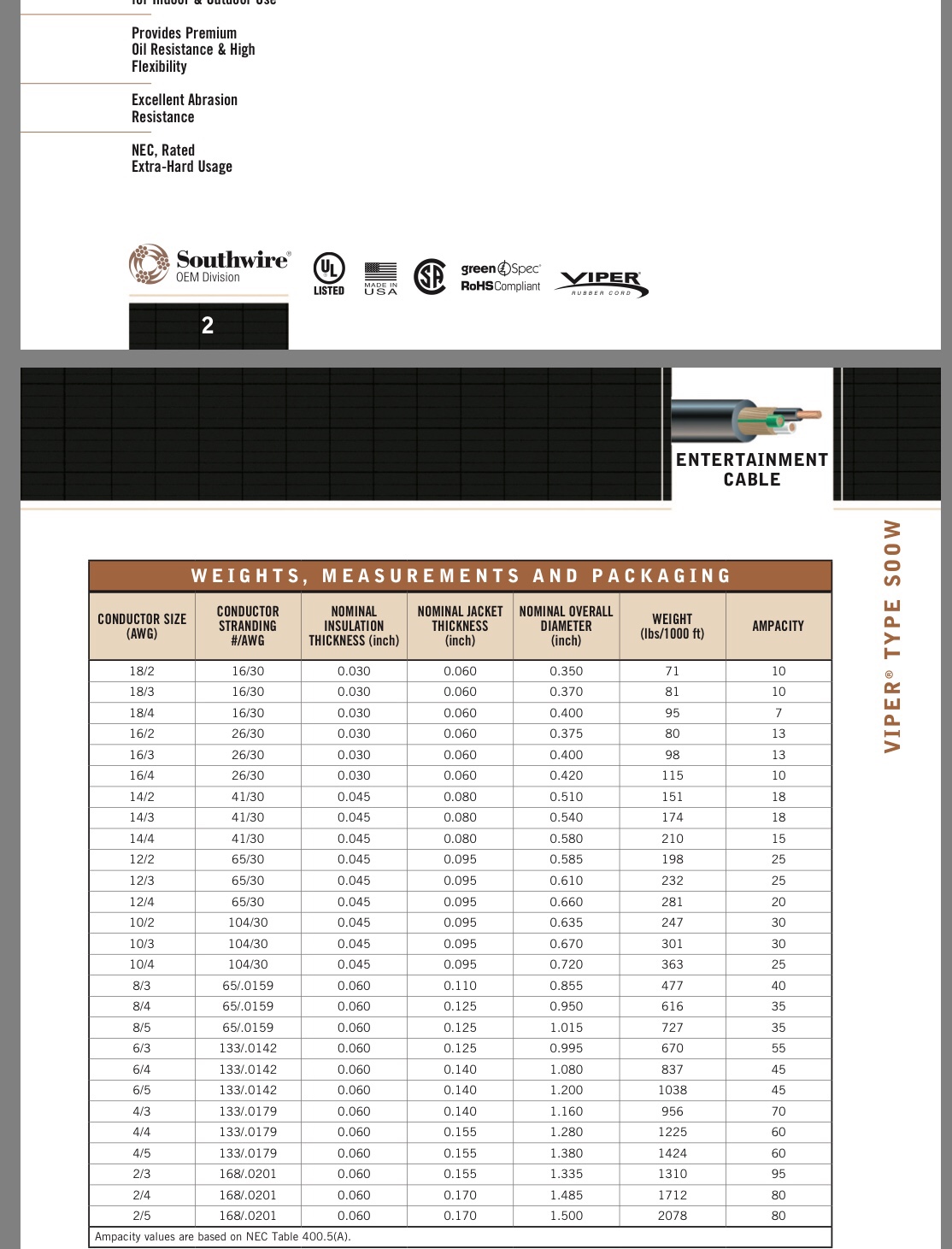

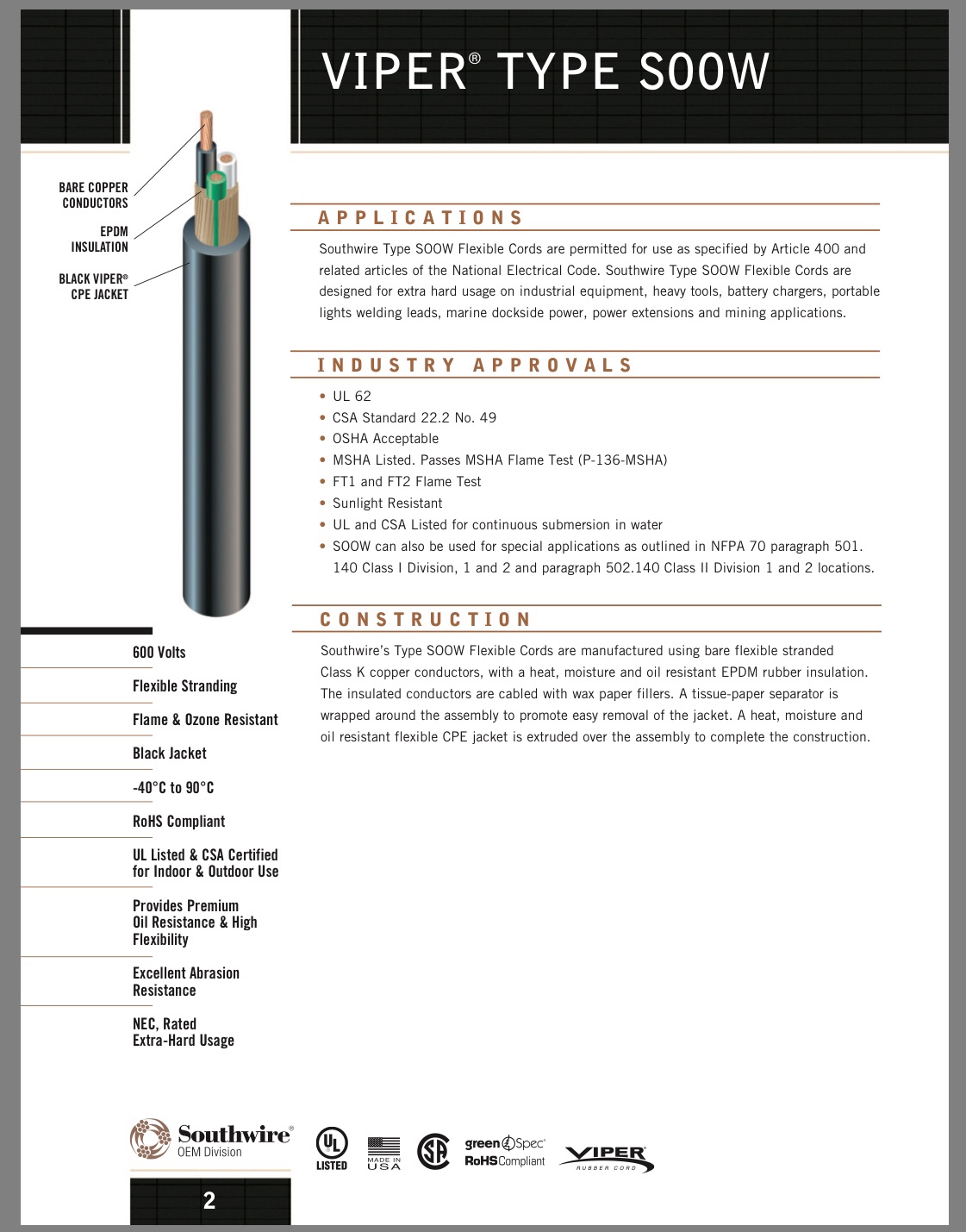

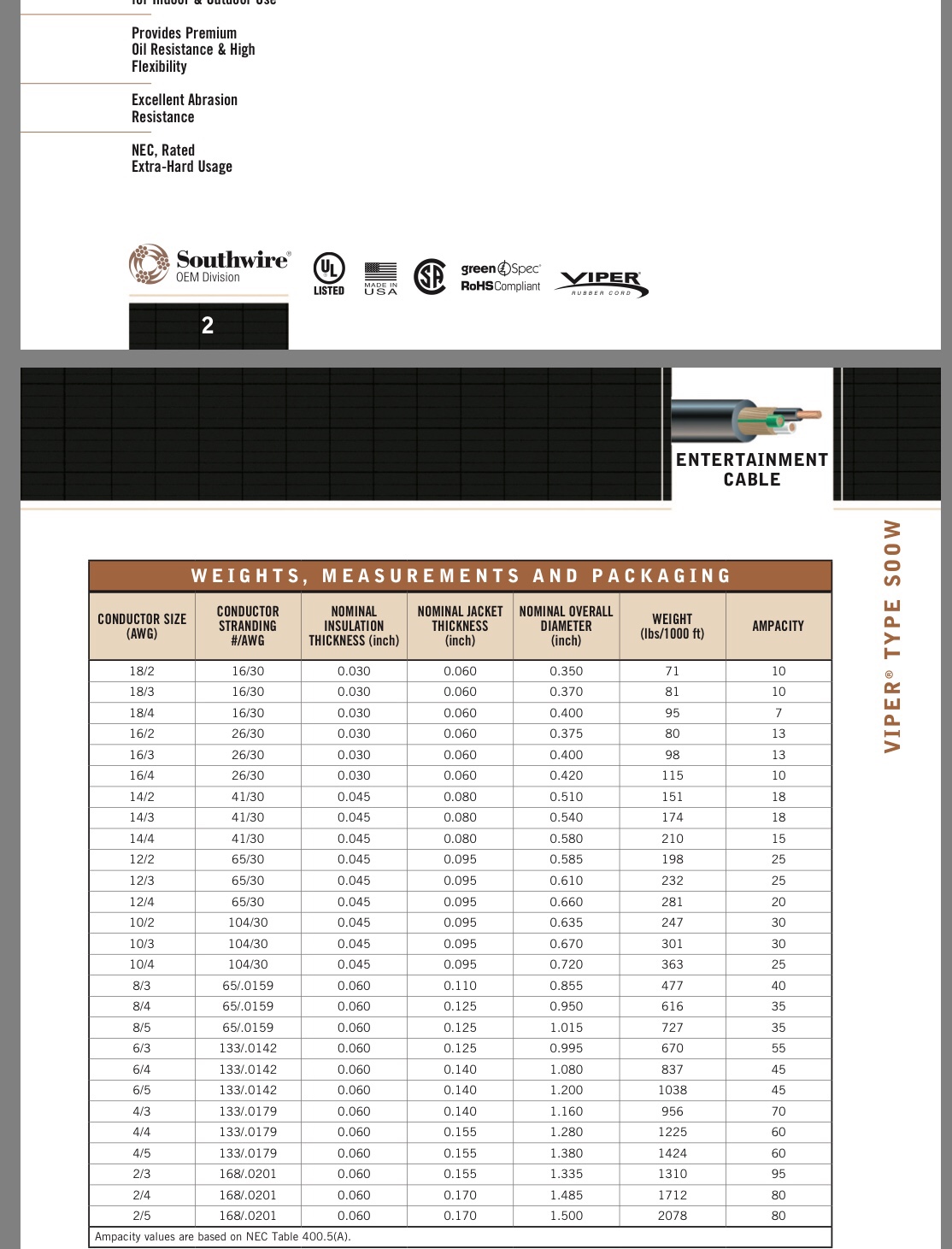

this is why i hate it when cable manufacturers publish ampacity values for their product. there are a multitude of installation conditions, environmental considerations, etc. that can modify the allowable ampacity of a cable. plus, code references can change with new nec editions. the southwire literature references nec table 400.5, which hasn't existed since the 2008 edition of the nec. yes, in 2011 it was changed to table 400.5(A)(1) and (2), a minor change but a change nonetheless.

anyway, the referenced table does indeed indicate a 25 amp limit on 10/4 seoow cable (column a in the table). but what is not addressed is the table footnotes which provide the basis for determining the allowable ampacity. the 25 amp limit (as opposed to 30 amp indicated in column b) is based on the assumption that three of the conductors in the cable are current carrying. if only two of the conductors are current carrying (i.e. two hots and no neutral for an element), then the cable falls into the column b ampacity values and the full 30 amp value can be used. now if this was a main power cord to a brew panel with 120v loads, then the cable would be limited to 25 amps, since three of the conductors are carrying current.

long story short, you can get the full 30 amps out of the 10/4 but as others have stated, it is big and bulky and probably not worth the hassle.

anyway, the referenced table does indeed indicate a 25 amp limit on 10/4 seoow cable (column a in the table). but what is not addressed is the table footnotes which provide the basis for determining the allowable ampacity. the 25 amp limit (as opposed to 30 amp indicated in column b) is based on the assumption that three of the conductors in the cable are current carrying. if only two of the conductors are current carrying (i.e. two hots and no neutral for an element), then the cable falls into the column b ampacity values and the full 30 amp value can be used. now if this was a main power cord to a brew panel with 120v loads, then the cable would be limited to 25 amps, since three of the conductors are carrying current.

long story short, you can get the full 30 amps out of the 10/4 but as others have stated, it is big and bulky and probably not worth the hassle.

augiedoggy

Well-Known Member

I actually suspected this was the case but I have to ask, Is there anyone out there running 6awg power cord from their outlet to their 30a brew panels? I would suspect there's far more people using 10/4 cable for this situation. Especially with their panels typically drawing around 25-26 amps with an element and pump running. I do not have a nuetral on my 30amp panel or a need for one with dc pumps so I guess im ok either way.this is why i hate it when cable manufacturers publish ampacity values for their product. there are a multitude of installation conditions, environmental considerations, etc. that can modify the allowable ampacity of a cable. plus, code references can change with new nec editions. the southwire literature references nec table 400.5, which hasn't existed since the 2008 edition of the nec. yes, in 2011 it was changed to table 400.5(A)(1) and (2), a minor change but a change nonetheless.

anyway, the referenced table does indeed indicate a 25 amp limit on 10/4 seoow cable (column a in the table). but what is not addressed is the table footnotes which provide the basis for determining the allowable ampacity. the 25 amp limit (as opposed to 30 amp indicated in column b) is based on the assumption that three of the conductors in the cable are current carrying. if only two of the conductors are current carrying (i.e. two hots and no neutral for an element), then the cable falls into the column b ampacity values and the full 30 amp value can be used. now if this was a main power cord to a brew panel with 120v loads, then the cable would be limited to 25 amps, since three of the conductors are carrying current.

long story short, you can get the full 30 amps out of the 10/4 but as others have stated, it is big and bulky and probably not worth the hassle.

I actually suspected this was the case but I have to ask, Is there anyone out there running 6awg power cord from their outlet to their 30a brew panels? I would suspect there's far more people using 10/4 cable for this situation. Especially with their panels typically drawing around 25-26 amps with an element and pump running. I do not have a nuetral on my 30amp panel or a need for one with dc pumps so I guess im ok either way.

you know, i never really thought about that before but i suppose it could be a code violation to run #10 cord to a 30 amp panel with 240v and 120v loads. would need the load to be above 25 amps at any given time. with a 5500 watt element, a chugger pump and a few indicating lights, it gets reeeal close. practically, it is fine if over 25 amps but technically, a violation.

Ok electrical experts, I need some advice,

I’m going to try to trade off or sell the 2/4 cable but here is what I’m thinking for the 10/4:

Run from breaker box to Spa panel, I will not have a need for neutral except for 12v power supply, everything else will be strictly 240 or DC on this setup, DC pump, DC SSR control, hell I could power the 12v supply from a separate outlet if necessary.

I will eventually add a second SSR and element but I don’t see a need to run both at the same time. I know I would be pushing it close but too close or no?

I’m going to try to trade off or sell the 2/4 cable but here is what I’m thinking for the 10/4:

Run from breaker box to Spa panel, I will not have a need for neutral except for 12v power supply, everything else will be strictly 240 or DC on this setup, DC pump, DC SSR control, hell I could power the 12v supply from a separate outlet if necessary.

I will eventually add a second SSR and element but I don’t see a need to run both at the same time. I know I would be pushing it close but too close or no?

My favorite ampacity table has the following footnote: "A conductor that is used to carry an unbalanced current from the other conductors is not considered to be a current carrying conductor." [emphasis added] I read that as saying two hots plus neutral gets to use the higher, two current carrying conductor limit. This makes sense, since whatever current flows thru the neutral is not flowing in one of the hots. For example: for a 28A 240V load and a 2A 120V load, one of the hots will be carrying 30A, the other hot will only carry 28A, and the neutral will carry 2A. Thus 30A source current and 30A return current, same as if you had a single 30A 240V load. Three current carrying conductors would be the case for 3-phase power, where all conductors carry pretty much the same current.this is why i hate it when cable manufacturers publish ampacity values for their product. there are a multitude of installation conditions, environmental considerations, etc. that can modify the allowable ampacity of a cable. plus, code references can change with new nec editions. the southwire literature references nec table 400.5, which hasn't existed since the 2008 edition of the nec. yes, in 2011 it was changed to table 400.5(A)(1) and (2), a minor change but a change nonetheless.

anyway, the referenced table does indeed indicate a 25 amp limit on 10/4 seoow cable (column a in the table). but what is not addressed is the table footnotes which provide the basis for determining the allowable ampacity. the 25 amp limit (as opposed to 30 amp indicated in column b) is based on the assumption that three of the conductors in the cable are current carrying. if only two of the conductors are current carrying (i.e. two hots and no neutral for an element), then the cable falls into the column b ampacity values and the full 30 amp value can be used. now if this was a main power cord to a brew panel with 120v loads, then the cable would be limited to 25 amps, since three of the conductors are carrying current.

long story short, you can get the full 30 amps out of the 10/4 but as others have stated, it is big and bulky and probably not worth the hassle.

Brew on

Youngster

Member

- Joined

- Mar 29, 2018

- Messages

- 23

- Reaction score

- 7

you know, i never really thought about that before but i suppose it could be a code violation to run #10 cord to a 30 amp panel with 240v and 120v loads. would need the load to be above 25 amps at any given time. with a 5500 watt element, a chugger pump and a few indicating lights, it gets reeeal close. practically, it is fine if over 25 amps but technically, a violation.

In Canada, 10/3 is good for 30A O/C, which is ment for 80% load (24A). However if the load is known, you could run 100% as long as the O/C’s are rated for it. O/C = Over Current

Edit: seoow could be rated for less however.

Last edited:

augiedoggy

Well-Known Member

In the United states the 80% rule only applies to continuous loads at 100% draw for over 3 hours straight. But people often mistake it for being required in other situations.

- Joined

- Mar 24, 2016

- Messages

- 558

- Reaction score

- 60

So if not 3 hrs one could exceed 80%? Assuming wires and other components are rated correctly.

augiedoggy

Well-Known Member

Yes exactly .. Thats when the actual amp rating of the cable is used otherwise we would just say 10awg is good for 24a right?So if not 3 hrs one could exceed 80%? Assuming wires and other components are rated correctly.

Most homes with 30a outlets use 10/4 wiring to feed that circuit in the walls and a 30a breaker. If the load exceeds a certain percentage for a certian amount of time I believe its the breaker thats designed to heat up and trip if im not mistaken but im no electrician. My homebrewing panel draws as much as 28amps at times for brewing but never steady and long enough to ever cause the breaker to trip or for thier to ever be an issue.

The idea is running the cable at 3hrs or more at 100% draw causes more heat and puts more strain on the insulation and connections if I understand it right.

The idea is running the cable at 3hrs or more at 100% draw causes more heat and puts more strain on the insulation and connections if I understand it right.

it really has more to do with the breaker in the upstream panel. heat is generated as current flows through the breaker which in turn warms the enclosed space that the breaker is contained in (the panel itself). enough heat in the panel and the breakers can be 'tricked' into thinking they are in an overcurrent condition and can cause false trips. by limiting the current to 80% for continuous loads, the heat generated is such that the breakers can stay within their 'normal' temperature operating range. plus the increased heat can shorten the life of the breaker.

i've seen dozens of industrial installations where panel doors are open and there are fans blowing on the panels, in an effort to get the excess heat away and prevent nuisance tripping. certainly not an ideal situation.

Similar threads

- Replies

- 21

- Views

- 670

- Replies

- 6

- Views

- 395

- Replies

- 6

- Views

- 419

Latest posts

-

-

For Sale Father's Passing: Homebrew Equip. Mega Sale

- Latest: leedspointbrew

-

-

-

-

-

-