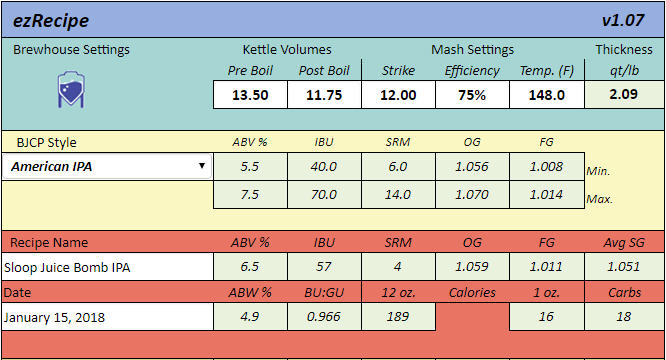

I'm still not convinced on the bucket vs glass O2 penetration. There's so much positive pressure why doesn't the co2 permeate out? However, if all else fails I'll try glass.

You don't have to move to glass. I would actually recommend better bottle. They're cheaper and much safer while also less permeable to O2 than the plastic buckets.

If you check out this chart, your bucket (HDPE) is 10 times more O2 permeable than a Better Bottle (PET).

http://www.evergreen-packaging.com/en/shownews.asp?id=70

edit: you don't have to go with Better Bottle so long as it's PET. I'm a fan of the Big Mouth Bubbler. The wide opening makes it easy to do dry hop additions or anything else you want to put in there. They're also easy to clean.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)