Not out of place at all. I’ve been reading some reviews of other people’s experiences with these yeasts and while there’s some good, there’s a lot of bad. I might scrap the idea of using them and just stick with British ale V.I don't want to be out of place here, but ya might think about the first time being on the homebrew scale?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New England IPA "Northeast" style IPA

- Thread starter Braufessor

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Dgallo

Instagram: bantam_brews

I personally hate the thiolized yeast. Makes the beers have a faint scent of bo and sulfur. Not to mention it takes over all of the hop character.Not out of place at all. I’ve been reading some reviews of other people’s experiences with these yeasts and while there’s some good, there’s a lot of bad. I might scrap the idea of using them and just stick with British ale V.

beervoid

Hophead & Pellet Rubber

Agree, didnt get much out of it so far.I personally hate the thiolized yeast. Makes the beers have a faint scent of bo and sulfur. Not to mention it takes over all of the hop character.

Have a phantasm beer in the planning with regular la3 to compare.

I've got 4oz. each of Nectaron, Mosaic and Nelson Sauvin.

Anyone mind giving me a quick recommendation on how to use them? Hot side vs. dry hop, particular ratios, one to skip for now and replace with something else? I'm not a Citra fan unfortunately. I'm an experienced brewer overall but a NEIPA newbie.

Anyone mind giving me a quick recommendation on how to use them? Hot side vs. dry hop, particular ratios, one to skip for now and replace with something else? I'm not a Citra fan unfortunately. I'm an experienced brewer overall but a NEIPA newbie.

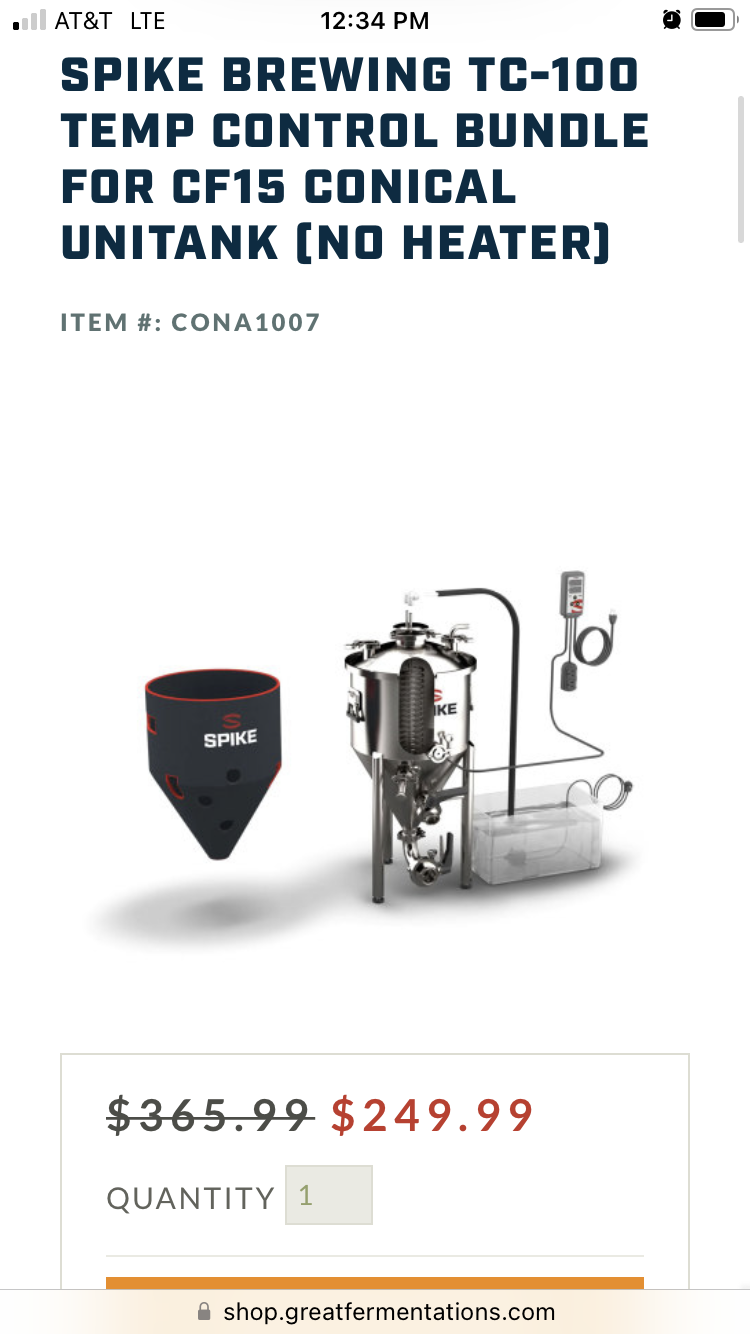

Do you keep head pressure while cold crashing?

As to how much i try to burp 1-2 times a day for 2 days, short shots of co2. Since long co2 burp seems to strip aroma in my experience.

I also do have a tc valve installed between tank and elbow.

I set the tank to 10 psi and start a CC, when it hits 2c it sits around 8 psi.

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$1.91

$29.95

Mastering Homebrew: The Complete Guide to Brewing Delicious Beer (Beer Brewing Bible, Homebrewing Book)

Goodwill Retail Services, Inc.

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

stickyfinger

Well-Known Member

Kind of interesting podcast.

These guys talk a lot about biotransformation. Surprising to me. Also, JC talks about the only way to know if a hop lot will be good is to do a bench trial. Makes sense to me.

Oh also. Not much love for any other hop products than T90

These guys talk a lot about biotransformation. Surprising to me. Also, JC talks about the only way to know if a hop lot will be good is to do a bench trial. Makes sense to me.

Oh also. Not much love for any other hop products than T90

beervoid

Hophead & Pellet Rubber

Kind of interesting podcast.

These guys talk a lot about biotransformation. Surprising to me. Also, JC talks about the only way to know if a hop lot will be good is to do a bench trial. Makes sense to me.

Oh also. Not much love for any other hop products than T90

Dang some heavy hitters in there. Very nice.

Waiting for Tree House podcast haha

elproducto

Well-Known Member

ihavenonickname

Well-Known Member

This thread should have a wiki summary page and FAQs…

Dgallo

Instagram: bantam_brews

There is a decent search feature at the top right. Def helps find specific postsThis thread should have a wiki summary page and FAQs…

Dgallo

Instagram: bantam_brews

I can send you a solid base recipe that you can tweak to meet your preference and ingredients on hand. I’ll have time after the kids go downAnyone have a base Double IPA recipe they like? @Dgallo ?

I don't have any cryo or anything, so would need to be without that.

TIA

elproducto

Well-Known Member

Amazing thanks.I can send you a solid base recipe that you can tweak to meet your preference and ingredients on hand. I’ll have time after the kids go down

jordanfrenzy

Well-Known Member

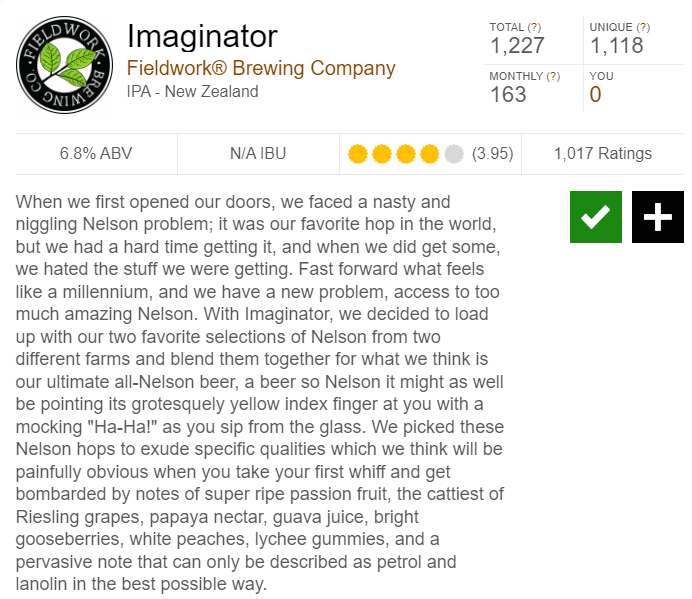

Dry hop should be no longer than 2 days for Southern Hemisphere hops or else you get the nothing but diesel dank.

100% Nelson totally agree.

OT, but this reminded me of a beer I had recently that was outstanding, Imaginator from Fieldwork in Berkeley:

The beer had all of the typical Nelson qualities but seemed much more intense and dank. I'm sure breweries have been blending hop lots forever, but doing it intentionally this way was interesting to me.

ihavenonickname

Well-Known Member

Kind of interesting podcast.

These guys talk a lot about biotransformation. Surprising to me. Also, JC talks about the only way to know if a hop lot will be good is to do a bench trial. Makes sense to me.

Oh also. Not much love for any other hop products than T90

They all touched on dry hop process at the end. Pretty interesting to me nobody mentioned dropping the temperature for crashing yeast or Dry Hopping and the contact times are about four days. No rousing from monkish is pretty surprising to me!

Last edited:

couchsending

Well-Known Member

- Joined

- Jun 21, 2016

- Messages

- 3,063

- Reaction score

- 2,256

Anyone have a base Double IPA recipe they like? @Dgallo ?

I don't have any cryo or anything, so would need to be without that.

TIA

Pilsner/2Row Blend

4% Dex

80ish theoretical IBU

1.012-1.014 FG target

100ppm Ca

3:1 Sulfate, Chloride

148, 162, 168 if you can step

Hop Extract @ 60

Simcoe @ 30

Nelson @ 10

180 WP Nelson/Idaho 7 @ 1.5#/bbl

Bootleg Biology Classic New England

-best source for Conan there is

Pitch at 64, ferment 66. Freerise on day 3 lots of o2. Big starter

let rest for 2 days after ferm is complete, then drop to 55 for 24 hours

Remove yeast

DH: 4#/bbl Nelson, Citra, Motueka

3:2:1

Rouse on day 2

Crash on day 3

Remove hops, lager for 5-7 days

Carb and serve

If you do everything right the result will be a big, bright, saturated, aromatic double IPA that’s incredibly drinkable

I've got 4oz. each of Nectaron, Mosaic and Nelson Sauvin.

Anyone mind giving me a quick recommendation on how to use them? Hot side vs. dry hop, particular ratios, one to skip for now and replace with something else? I'm not a Citra fan unfortunately. I'm an experienced brewer overall but a NEIPA newbie.

Sorry to be the super newb here, will try one more time. I brewed a Brown Ale yesterday and aiming for a NEIPA next. Anyone mind giving a quick recommendation on the hops above - Nectaron, Mosaic and Nelson? Using them late boil vs dry, using perhaps just 2 of the 3 and adding another, going for all 3? If you had each of these on hand, what would you be thinking for using them? I doubt I can go wrong but am open to suggestions.

couchsending

Well-Known Member

- Joined

- Jun 21, 2016

- Messages

- 3,063

- Reaction score

- 2,256

Sorry to be the super newb here, will try one more time. I brewed a Brown Ale yesterday and aiming for a NEIPA next. Anyone mind giving a quick recommendation on the hops above - Nectaron, Mosaic and Nelson? Using them late boil vs dry, using perhaps just 2 of the 3 and adding another, going for all 3? If you had each of these on hand, what would you be thinking for using them? I doubt I can go wrong but am open to suggestions.

5 gallons?

2oz Nectaron, 2oz Nelson in WP

DH with the rest

5 gallons?

2oz Nectaron, 2oz Nelson in WP

DH with the rest

Yes, And thanks!

couchsending

Well-Known Member

- Joined

- Jun 21, 2016

- Messages

- 3,063

- Reaction score

- 2,256

This is just a general recommendation for anyone on here… instead of just following recipes blindly or just taking advice from people on here….

SMELL YOUR HOPS

The quality of Homebrew level hops is variable at best. Hell the quality of pro level hops is variable at best. Put the hops that smell the best in the DH. Use the ones that don’t smell as good on the hotside or throw them away.

If the recipe calls for a 70:30 ratio of Citra:Nelson but you open the Citra and it’s super onion/garlic but the Nelson is ripping then swap the ratios… might not be the exact beer but the beer will be much better in the end.

SMELL YOUR HOPS

The quality of Homebrew level hops is variable at best. Hell the quality of pro level hops is variable at best. Put the hops that smell the best in the DH. Use the ones that don’t smell as good on the hotside or throw them away.

If the recipe calls for a 70:30 ratio of Citra:Nelson but you open the Citra and it’s super onion/garlic but the Nelson is ripping then swap the ratios… might not be the exact beer but the beer will be much better in the end.

The info from Monkish was a bit surprising to me as well. I had some Monkish hazies several years ago at the brewery, and I have had a few over the past year or two at special events. They are a bit too overboard on the hop saturation for my preferences, but I just assumed they must be doing something special to get that level of saturation. Monkish (Henry Nguyen) indicated they like T-90 pellets over other hop product and I believe they said 3-5 days of contact time at fermentation temps.They all touched on dry hop process at the end. Pretty interesting to me nobody mentioned dropping the temperature for crashing yeast or Dry Hopping and the contact times are about four days. No rousing from monkish is pretty surprising to me!

One of the breweries was using some type of hop cannon device. Was that Trillium or Weldwerks?

CyberFox

Well-Known Member

- Joined

- Mar 29, 2022

- Messages

- 230

- Reaction score

- 100

That was Trillium with the device. It's really interesting how most of the pro breweries dry hop warm and usually for 3+ days. Monkish even said that they mimicked Vinnie Cilurzo's West Coast IPA dry hop process. Nguyen said that they are usually grain-to-glass in 27 days due to extensive cold crashing and he wishes that they could lager even longer. Definitely not what I expected from them. Pretty cool to listen to.The info from Monkish was a bit surprising to me as well. I had some Monkish hazies several years ago at the brewery, and I have had a few over the past year or two at special events. They are a bit too overboard on the hop saturation for my preferences, but I just assumed they must be doing something special to get that level of saturation. Monkish (Henry Nguyen) indicated they like T-90 pellets over other hop product and I believe they said 3-5 days of contact time at fermentation temps.

One of the breweries was using some type of hop cannon device. Was that Trillium or Weldwerks?

beervoid

Hophead & Pellet Rubber

They dont really have a choice imho if you want your cans to be stable you need to work with the creep, I'd imagine they know their cans are traded and are trying to mitigate the risk.That was Trillium with the device. It's really interesting how most of the pro breweries dry hop warm and usually for 3+ days. Monkish even said that they mimicked Vinnie Cilurzo's West Coast IPA dry hop process. Nguyen said that they are usually grain-to-glass in 27 days due to extensive cold crashing and he wishes that they could lager even longer. Definitely not what I expected from them. Pretty cool to listen to.

couchsending

Well-Known Member

- Joined

- Jun 21, 2016

- Messages

- 3,063

- Reaction score

- 2,256

It all depends on your yeast, fermentability of your wort, the enzyme load of your hops… etc

There is no set time. Could be 24 hours could be 5 days.

Gravity and forced VDK tests are your only ways of truly knowing.

There is no set time. Could be 24 hours could be 5 days.

Gravity and forced VDK tests are your only ways of truly knowing.

Last edited:

CyberFox

Well-Known Member

- Joined

- Mar 29, 2022

- Messages

- 230

- Reaction score

- 100

Thanks for a good answer. I was looking for an average, which is what you gave me. It wasn't easy to find, but after a lot more digging I found out that the average time it takes for hop creep to run its course is usually 4-6 days with healthy yeast.It all depends on your yeast, fermentability of your wort, the enzyme load of your hops… etc

There is no set time. Could be 24 hours could be 5 days.

Gravity and forces VDK tests are your only ways of truly knowing.

Dry hop length by brewery:

Monkish: 4-5 days

Other Half: 5 days

Treehouse: 4-6 days

Weldwerks: 4-6 days

Great Notion: 6+ days

Fort George: 4-10 days

I found more extreme examples of how long it takes to pass a VDK test:

pFriem at Craft Brewers Conference: up to 14 days

Russian River at Shellhammer's panel: 10-15 days.

Beersmith article: up to 45 days

- Joined

- Nov 28, 2020

- Messages

- 351

- Reaction score

- 1,240

The info from Monkish was a bit surprising to me as well. I had some Monkish hazies several years ago at the brewery, and I have had a few over the past year or two at special events. They are a bit too overboard on the hop saturation for my preferences, but I just assumed they must be doing something special to get that level of saturation. Monkish (Henry Nguyen) indicated they like T-90 pellets over other hop product and I believe they said 3-days of contact time at fermentation temps.

One of the breweries was using some type of hop cannon device. Was that Trillium or Weldwe

You can always use Aldc enzyme.Thanks for a good answer. I was looking for an average, which is what you gave me. It wasn't easy to find, but after a lot more digging I found out that the average time it takes for hop creep to run its course is usually 4-6 days with healthy yeast.

Dry hop length by brewery:

Monkish: 4-5 days

Other Half: 5 days

Treehouse: 4-6 days

Weldwerks: 4-6 days

Great Notion: 6+ days

Fort George: 4-10 days

I found more extreme examples of how long it takes to pass a VDK test:

pFriem at Craft Brewers Conference: up to 14 days

Russian River at Shellhammer's panel: 10-15 days.

Beersmith article: up to 45 days

CyberFox

Well-Known Member

- Joined

- Mar 29, 2022

- Messages

- 230

- Reaction score

- 100

True, and that's a good point, but it's also good to know how long to dry hop warm if you don't have the ALDC enzyme. North Park uses it and I'm pretty sure Trillium does too. They both dry hop warm (70F for North Park and 60F for Trillium) for 2-3 days, which is likely possible due to the ALDC enzyme.You can always use Aldc enzyme.

Last edited:

- Joined

- Nov 28, 2020

- Messages

- 351

- Reaction score

- 1,240

Russian river uses too.True, and that's a good point, but it's also good to know how long to dry hop warm if you don't have the ALDC enzyme. North Park uses it and I'm pretty sure Trillium does too. They both dry hop warm (70F for North Park and 60F for Trillium) for 2-3 days, which is likely possible due to the ALDC enzyme.

- Joined

- Nov 28, 2020

- Messages

- 351

- Reaction score

- 1,240

I personally dry hop on the cooler end and pull better flavor and aromas then warmer temps. I feel like warmer temps have a very similar taste it doesn’t matter what hop you use. When I first started brewing I would dry hop at 68 degrees during high Krausen and I wasn’t a big fan. Cooler temp dry hop is the way to go.

beervoid

Hophead & Pellet Rubber

You can shorten it by adding a small fermentation hop chargeThanks for a good answer. I was looking for an average, which is what you gave me. It wasn't easy to find, but after a lot more digging I found out that the average time it takes for hop creep to run its course is usually 4-6 days with healthy yeast.

Dry hop length by brewery:

Monkish: 4-5 days

Other Half: 5 days

Treehouse: 4-6 days

Weldwerks: 4-6 days

Great Notion: 6+ days

Fort George: 4-10 days

I found more extreme examples of how long it takes to pass a VDK test:

pFriem at Craft Brewers Conference: up to 14 days

Russian River at Shellhammer's panel: 10-15 days.

Beersmith article: up to 45 days

CyberFox

Well-Known Member

- Joined

- Mar 29, 2022

- Messages

- 230

- Reaction score

- 100

Dry hopping cold seems to work for some, but not others (and vice versa). It just goes to show that you can still get good results using different techniques. It's interesting that most breweries seem to dry hop warm post-fermentation. It could just be tradition for all I know.I personally dry hop on the cooler end and pull better flavor and aromas then warmer temps. I feel like warmer temps have a very similar taste it doesn’t matter what hop you use. When I first started brewing I would dry hop at 68 degrees during high Krausen and I wasn’t a big fan. Cooler temp dry hop is the way to go.

I've heard of this technique, but I don't really understand how it works. Won't the post-fermentation dry hop still have the enzymes that cause the secondary fermentation (and in much bigger numbers)?You can shorten it by adding a small fermentation hop charge

beervoid

Hophead & Pellet Rubber

It will free up what unfermentable sugars there are so yeast can work fast on it while its activeDry hopping cold seems to work for some, but not others (and vice versa). It just goes to show that you can still get good results using different techniques. It's interesting that most breweries seem to dry hop warm post-fermentation. It could just be tradition for all I know.

I've heard of this technique, but I don't really understand how it works. Won't the post-fermentation dry hop still have the enzymes that cause the secondary fermentation (and in much bigger numbers)?

CyberFox

Well-Known Member

- Joined

- Mar 29, 2022

- Messages

- 230

- Reaction score

- 100

Got it. That's good to know. I learned from the podcast that North Park uses both that technique and ALDC enzyme.It will free up what unfermentable sugars there are so yeast can work fast on it while its active

Dgallo

Instagram: bantam_brews

It’s more about logistics. When you cold crash you stop the yeats activity, so when you dryhop at that temp it causes the hops to sink. This is an issue for anyone with a conical fv but especially the pros because it’s far more difficult for them to get effective rousing in 5bbl+ sized fermenters. By doing it warmer they are getting better extraction since the hops won’t sink to the bottom and get stuck in the cone and the compound will be more harmonious mixed. Also since they are anticipating the hop creep they know they will get some convectionDry hopping cold seems to work for some, but not others (and vice versa). It just goes to show that you can still get good results using different techniques. It's interesting that most breweries seem to dry hop warm post-fermentation. It could just be tradition for all I know.

Also notice most of the breweries being mentioned are on the west coast and the standard hazy is more bitter and astringent then those on the east coast. For example, I’ve drank a lot of monkish and I don’t think I’ve ever had a ipa from them that didn’t have some level of hop burn

Last edited:

beervoid

Hophead & Pellet Rubber

I think its all about balance, time vs temperature vs agetation.It’s more about logistics. When you cold crash you stop the yeats activity, so when you dryhop at that temp it causes the hops to sink. This is an issue for anyone with a conical fv but especially the pros because it’s far more difficult for them to get effective rousing in 5bbl+ sized fermenters. By doing it warmer they are getting better extraction since the hops won’t sink to the bottom and get stuck in the cone and the compound will be more harmonious mixed. Also since they are anticipating the hop creep they know they will get some convection

Also notice most of the breweries being mentioned are on the west coast and the standard hazy is more bitter and astringent then those on the east coast. For example, I’ve drank a lot of monkish and I don’t think I’ve ever had a ipa from them that didn’t have some level of hop burn

And all these parameters change depending on hop quality, hop cultivar, vessel size, vessel geometry.

Try finding a balance that works for you with parameters that change all the time is the black magic of brewing imho.

The pros at least have advantage to select their hops which makes it quiet a bit more predictable what sort of character you will get from lot nr X with process Y.

I've done both warm and cold dryhopping and had fantastic and not good results with both.

CyberFox

Well-Known Member

- Joined

- Mar 29, 2022

- Messages

- 230

- Reaction score

- 100

Good points. What would you consider the best overall temp for dry hopping at this point? Also, what is your opinion on grinding hop pellets into a powder for better extraction at cold temperatures?It’s more about logistics. When you cold crash you stop the yeats activity, so when you dryhop at that temp it causes the hops to sink. This is an issue for anyone with a conical fv but especially the pros because it’s far more difficult for them to get effective rousing in 5bbl+ sized fermenters. By doing it warmer they are getting better extraction since the hops won’t sink to the bottom and get stuck in the cone and the compound will be more harmonious mixed. Also since they are anticipating the hop creep they know they will get some convection

Also notice most of the breweries being mentioned are on the west coast and the standard hazy is more bitter and astringent then those on the east coast. For example, I’ve drank a lot of monkish and I don’t think I’ve ever had a ipa from them that didn’t have some level of hop burn

Noob_Brewer

Well-Known Member

For me, I think the balance is at 56-57F for a total of 48hrs contact time. After I soft crash to 50 for 36hrs, I will gently let it rise to 56. Then I measure my DHs out and put them in a tupperware container to warm up to room temps for about 1hr. If Im using a whole 2oz pack, Ill keep it sealed in its bag. I feel like letting the hops warm to room temp facilitates them breaking to pieces easier once you put them in. I've also moved to ONE DH lately which Im actually liking but Ive also limited my DH to 6-10oz depending on the strength of the beer.Good points. What would you consider the best overall temp for dry hopping at this point? Also, what is your opinion on grinding hop pellets into a powder for better extraction at cold temperatures?

While DHing at 56F and letting the hops warm up to room temp, I do get a nice carpet of hops all broken up at the top of the beer (you will get some that sink). The hop "carpet" will drop out slowly over about 24 or so hrs. I start to cold crash at 24hrs post DH so that Im kegging 24hrs after that. This is what Im currently doing and been loving the results. Although its not a NEIPA, but my Double west coast style IPA had 8oz of hops (some of that was columbus and citra lupomax) and this beers aroma is easily one of the most pleasantly potent that I have had in quite some time.

EDIT: I will edit this to say that DH process is important here (especially limiting O2), I think the hop quality is also critical. SO its difficult to tease out DH process vs hop quality if both are good.

CyberFox

Well-Known Member

- Joined

- Mar 29, 2022

- Messages

- 230

- Reaction score

- 100

Awesome info and thanks for the details of your process. I've heard people dry hopping anywhere from 34-72F. I was thinking of trying to dry hop at 38F (carbonation temp) with ground up pellets for better extraction. My main goal is to get maximum aroma that showcases the best example of each hop.For me, I think the balance is at 56-57F for a total of 48hrs contact time. After I soft crash to 50 for 36hrs, I will gently let it rise to 56. Then I measure my DHs out and put them in a tupperware container to warm up to room temps for about 1hr. If Im using a whole 2oz pack, Ill keep it sealed in its bag. I feel like letting the hops warm to room temp facilitates them breaking to pieces easier once you put them in. I've also moved to ONE DH lately which Im actually liking but Ive also limited my DH to 6-10oz depending on the strength of the beer.

While DHing at 56F and letting the hops warm up to room temp, I do get a nice carpet of hops all broken up at the top of the beer (you will get some that sink). The hop "carpet" will drop out slowly over about 24 or so hrs. I start to cold crash at 24hrs post DH so that Im kegging 24hrs after that. This is what Im currently doing and been loving the results. Although its not a NEIPA, but my Double west coast style IPA had 8oz of hops (some of that was columbus and citra lupomax) and this beers aroma is easily one of the most pleasantly potent that I have had in quite some time.

EDIT: I will edit this to say that DH process is important here (especially limiting O2), I think the hop quality is also critical. SO its difficult to tease out DH process vs hop quality if both are good.

Similar threads

- Replies

- 4

- Views

- 1K

- Replies

- 2

- Views

- 214