Thanks Braufessor. I just don't get the impatience.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New England IPA "Northeast" style IPA

- Thread starter Braufessor

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

popquizkid

Well-Known Member

- Joined

- Oct 29, 2013

- Messages

- 216

- Reaction score

- 89

I know people do successfully make these beers in 7-10 days. I also know many/most commercial breweries produce these beers in that range too. However, that said, almost every batch of NEIPA that I have ever been disappointed in was a batch i tried to push through in 7-10 days as opposed to 12-14. I have just always found the extra few days lets the beer clean up a bit and pushing it has always given me a bit "harsher" hop profile.... more grassy, more vegetal.

I don't doubt anyone else's ability in doing it..... I just know that with my system, and my process, I have always produced better beer with a few extra days on this style.

I agree. 10 days in the fermentor and then a week in the keg conditioning is when I think mine start drinking the best. The hop flavor better integrates into the beer by that point and smooths out a bit.

When I was at Bissell Brothers and drank Reciprocal on tap in their tasting room I thought the same thing. My guess is it was a really fresh. It was delicious -- but a little rough around the edges and I thought it might be almost too young. A 5 days later my cans from the same batch were drinking wonderfully...great beer. The beer improved within that first week as the cans sat in the fridge.

Northern_Brewer

British - apparently some US company stole my name

John Kimmich's view : "I tried it every day for 10 weeks, and I felt that Heady Topper is at it's best at 10 weeks" [they release at 28 days]

(HBT strips the time link, he talks about ageing at 3m48s)

(HBT strips the time link, he talks about ageing at 3m48s)

stickyfinger

Well-Known Member

Everyone has their own taste preference on when IPAs taste best. Seems to depend on a lot from beer to beer as well, along with process.

mjjunior10

Well-Known Member

- Joined

- Feb 4, 2016

- Messages

- 45

- Reaction score

- 17

It is a relative thing. Even the mood at that try day it make difference about the taste.

First, it's not impatience, it's just when the beer is ready for me.

Second, the floating dip tubes make a big difference. Without them I could see the beers needing another 5-7 days.

As it is, I notice no difference between day 7-10 and day 30 other than appearance (it clears a bit more obviously)

Second, the floating dip tubes make a big difference. Without them I could see the beers needing another 5-7 days.

As it is, I notice no difference between day 7-10 and day 30 other than appearance (it clears a bit more obviously)

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

stickyfinger

Well-Known Member

yeah, the floating dip tube “ages” a beer relative to beers drawn from below in that bigger particles and yeast disappear more quickly

stickyfinger

Well-Known Member

This blog post is germane to this conversation on timing when using kveik - http://www.garshol.priv.no/blog/393.html

This blog post is germane to this conversation on timing when using kveik - http://www.garshol.priv.no/blog/393.html

Kveik really is some fascinating stuff. Lars posted an article a few weeks ago with evidence to indicate that it is unlike any other Sacc C strain we know:

https://www.frontiersin.org/articles/10.3389/fmicb.2018.02137/full

It's nuts how fast it takes off. A few months ago, I forgot who I was messing with and didn't put the spunding valve on for a few hours post pitch and psi was already up around 60.

stickyfinger

Well-Known Member

he showed a picture of it at 30 mins and it was foaming on top! has anyone used the OYL Hornindal strain? I was excited til I read on Lars’s blog about milky caramel from the original mixed strain. Also, have you tried pitching 1 tsp for 5G?! I think he said that is all you need and it gives more esters then

Adi from Omega regularly attends our Homebrew group meetings and always sings it's praises.

I haven't used it yet myself but a few of the guys in the group have and it explodes like you mentioned. One guy did a NEIPA with 1318 against it and I preferred the 1318 but it wasn't by much

I haven't used it yet myself but a few of the guys in the group have and it explodes like you mentioned. One guy did a NEIPA with 1318 against it and I preferred the 1318 but it wasn't by much

stickyfinger

Well-Known Member

Adi from Omega regularly attends our Homebrew group meetings and always sings it's praises.

I haven't used it yet myself but a few of the guys in the group have and it explodes like you mentioned. One guy did a NEIPA with 1318 against it and I preferred the 1318 but it wasn't by much

the Hornindal strain?

he showed a picture of it at 30 mins and it was foaming on top! has anyone used the OYL Hornindal strain? I was excited til I read on Lars’s blog about milky caramel from the original mixed strain. Also, have you tried pitching 1 tsp for 5G?! I think he said that is all you need and it gives more esters then

I have not tried to under-pitch. I need to try it though because my standard practice is the exact opposite.

I have used the Hornindal quite a bit mostly from Omega but I tried the one from Escarpment labs too. In fact, that's the strain that was used in the batch I shipped @PianoMan today. I used some Ultra Ferm on that batch and was aiming for a brut. This was the first time using that stuff and it didn't finish quite as low as expected but it is a bit more dry consequently with a bit more perceived bitterness than a traditional NE. Since I was shooting for a brut, I wanted over 3 volumes so this batch was fermented at 100F with pressure exceeding 60 psi. I learned the hard way not to try pulling a gravity sample at that pressure through CBDS and a picnic tap. The screw on that floating dip tube didn't hold up and I had to go back in after the cold crash to replace the dip tube.

The fact it was doing it's thing 30 minutes in doesn't surprise me at all. It really is a different animal. If you're a heavy sleeper, you better set your alarm so you can get your dry hops in and tighten the spunding valve for natural carbonation before it's done. I usually start in the neighborhood of 1.060 and 12-15hrs later I'm between 1.015-1.020. I leave my spunding valve around 10psi until I get the dry hops in to help prevent a beer volcano. After the dry hops are in, you'll need to tighten it so you can reach ~40psi to achieve natural carbonation at temps in excess of 90F.

I haven't gotten anything out of Hornindal that I would describe as milky caramel from either they Omega or Escarpment Labs strain.

stickyfinger

Well-Known Member

I have not tried to under-pitch. I need to try it though because my standard practice is the exact opposite.

I have used the Hornindal quite a bit mostly from Omega but I tried the one from Escarpment labs too. In fact, that's the strain that was used in the batch I shipped @PianoMan today. I used some Ultra Ferm on that batch and was aiming for a brut. This was the first time using that stuff and it didn't finish quite as low as expected but it is a bit more dry consequently with a bit more perceived bitterness than a traditional NE. Since I was shooting for a brut, I wanted over 3 volumes so this batch was fermented at 100F with pressure exceeding 60 psi. I learned the hard way not to try pulling a gravity sample at that pressure through CBDS and a picnic tap. The screw on that floating dip tube didn't hold up and I had to go back in after the cold crash to replace the dip tube.

The fact it was doing it's thing 30 minutes in doesn't surprise me at all. It really is a different animal. If you're a heavy sleeper, you better set your alarm so you can get your dry hops in and tighten the spunding valve for natural carbonation before it's done. I usually start in the neighborhood of 1.060 and 12-15hrs later I'm between 1.015-1.020. I leave my spunding valve around 10psi until I get the dry hops in to help prevent a beer volcano. After the dry hops are in, you'll need to tighten it so you can reach ~40psi to achieve natural carbonation at temps in excess of 90F.

I haven't gotten anything out of Hornindal that I would describe as milky caramel from either they Omega or Escarpment Labs strain.

great info. thx. i wonder if the OYL version is a single strain as opposed to the usual Kveik blend of strains and I also wonder if the milky caramel comes in on a low pitch. In either case, thx and relieved to hear no milky caramel, lol

are you fermenting in a corny and dry hopping loose? i have done that several times but got burned once when transporting to a party. it totally clogged after the car ride and then when i let it rest overnight it was pouring fine again!

great info. thx. i wonder if the OYL version is a single strain as opposed to the usual Kveik blend of strains and I also wonder if the milky caramel comes in on a low pitch. In either case, thx and relieved to hear no milky caramel, lol

are you fermenting in a corny and dry hopping loose? i have done that several times but got burned once when transporting to a party. it totally clogged after the car ride and then when i let it rest overnight it was pouring fine again!

That is exactly what I'm doing but I have the screen over the dip tube. Shortly after I started keg fermenting in the spring, I wanted to bring some kegs to serve at a homebrew festival and I was paranoid about experiencing exactly what you described. Last thing I wanted was to show up with 10G of beer and not be able to serve a glass. As a precaution, I pushed those over to a separate SV while everything was settled on the bottom. Worked like a champ!

My biggest issue has been the dip tube coming apart. But, I think that short screw is pretty suspect anyhow so now I make sure to tighten it every time.

stickyfinger

Well-Known Member

That is exactly what I'm doing but I have the screen over the dip tube. Shortly after I started keg fermenting in the spring, I wanted to bring some kegs to serve at a homebrew festival and I was paranoid about experiencing exactly what you described. Last thing I wanted was to show up with 10G of beer and not be able to serve a glass. As a precaution, I pushed those over to a separate SV while everything was settled on the bottom. Worked like a champ!

My biggest issue has been the dip tube coming apart. But, I think that short screw is pretty suspect anyhow so now I make sure to tighten it every time.

I've had some issues moving an entire batch over to a SV using the CBDS. It clogged a few times. Maybe I'll try it again after letting the keg sit until the last minute. I'll push it out with CO2 and do a split batch, half in a carboy in case I need to use that for the next party. The CBDS seems to work awesomely for serving a few pints per day, but it might clog if you try to push the filter screen too much by filtering an entire keg before the big particles have fallen down closer to the bottom. It always seems to come back though if you let it rest or push some CO2 through the beer out fitting to push out the clogging material.

I wasn't really paying attention to the screw on the CBDS when I first got it either, like a *******. Then, I realized you can unscrew it completely to clean and then just reassemble and crank it down super tight when ready to use again. The threads only go in a short distance, and it is completely sealed so that it can never get beer inside of the SS ball at the top.

I'm never going to transport a beer to a party using the CBDS again unless I know it has zero to minimal hops in it though.

Yes...sorry I guess that doesn't read clearly without contextthe Hornindal strain?

SRJHops

Why did the rabbit like NEIPA's so much?

This question might have been covered earlier, but what really contributes to the faster oxidation of NEIPA's? Is it the big post-boil whirlpool hop charge, the bio-transformation hop charge, the big dry hop charge, or the recipe? Something else?

I see some earlier posts suggesting it could be the flaked oats, which I have been using. I could switch to flaked barley or flaked wheat if that would help.

I do intend to work on significantly reducing the exposure to oxygen. I get that. But I've brewed some good IPA's that were transferred to secondary, had several dry hop additions well past fermentation, and used a bottling bucket -- and they didn't oxidize very much. But my NEIPA's are oxidizing before I can even get them into the bottle. What's going on?

I see some earlier posts suggesting it could be the flaked oats, which I have been using. I could switch to flaked barley or flaked wheat if that would help.

I do intend to work on significantly reducing the exposure to oxygen. I get that. But I've brewed some good IPA's that were transferred to secondary, had several dry hop additions well past fermentation, and used a bottling bucket -- and they didn't oxidize very much. But my NEIPA's are oxidizing before I can even get them into the bottle. What's going on?

THAT, my friend, is the 64 million dollar question.

This question might have been covered earlier, but what really contributes to the faster oxidation of NEIPA's? Is it the big post-boil whirlpool hop charge, the bio-transformation hop charge, the big dry hop charge, or the recipe? Something else?

I see some earlier posts suggesting it could be the flaked oats, which I have been using. I could switch to flaked barley or flaked wheat if that would help.

I do intend to work on significantly reducing the exposure to oxygen. I get that. But I've brewed some good IPA's that were transferred to secondary, had several dry hop additions well past fermentation, and used a bottling bucket -- and they didn't oxidize very much. But my NEIPA's are oxidizing before I can even get them into the bottle. What's going on?

Flaked adjuncts may be some of it but the bottom line is what defines the style is a TON of late/dry hop additions and flavor/aroma compounds are highly susceptible to oxidation. Once you diminish those with even a tiny bit of dissolved oxygen in the finished product, you're left with a boring beer. Unless you're bottle spunding (which I wouldn't recommend unless you are dialed in on your process) there's no good way to bottle without introducing unacceptable levels of DO. Sure the yeast will eat the oxygen when conditioning but the time between leaving the fermenter and yeast activity starting again in the bottle is enough to kill your flavor significantly. Then you have cap ingress over time...

Bottle conditioning NEIPAs is an uphill battle.

stickyfinger

Well-Known Member

Flaked adjuncts may be some of it but the bottom line is what defines the style is a TON of late/dry hop additions and flavor/aroma compounds are highly susceptible to oxidation. Once you diminish those with even a tiny bit of dissolved oxygen in the finished product, you're left with a boring beer. Unless you're bottle spunding (which I wouldn't recommend unless you are dialed in on your process) there's no good way to bottle without introducing unacceptable levels of DO. Sure the yeast will eat the oxygen when conditioning but the time between leaving the fermenter and yeast activity starting again in the bottle is enough to kill your flavor significantly. Then you have cap ingress over time...

Bottle conditioning NEIPAs is an uphill battle.

if u bottle with a beer gun and purge the bottles with co2 and purge headspace, you might be better off. i guess you are probably bottling cuz you dont have co2 though.

stickyfinger

Well-Known Member

bottling from a keg is fine...it's bottle conditioning that is the problem

i think someone bottle conditioned using co2 purges and had some success

SRJHops

Why did the rabbit like NEIPA's so much?

I don't have any co2 (yet), but that could be my next investment. If it's really the amount of hops in the whirlpool and/or dry hopping that is the problem, in theory I could dial those back. My regular IPA's don't get as much oxidation.

I do plan to just dry hop once, on day 2, as Braufessor is doing. But I was planning a pretty big charge. No secondary; fill bottles straight from fermenter on day 14 and use carbonation tablets for priming sugar so I can skip the bottling bucket. Short of using co2 purges, that should introduce as little oxygen as possible I would think...

I do plan to just dry hop once, on day 2, as Braufessor is doing. But I was planning a pretty big charge. No secondary; fill bottles straight from fermenter on day 14 and use carbonation tablets for priming sugar so I can skip the bottling bucket. Short of using co2 purges, that should introduce as little oxygen as possible I would think...

Exposure to oxygen is the problem, hop aroma and taste are greatly affected by this... all negative. Without elaborate measures bottling these beers is inviting oxidation although your plan to bottle from the fermentor may be a good solution to slow the inevitable. I had the disappointment of fairly quick (1week) oxidation after bottling these beers and immediately turned to kegging and have not had an issue since. I bought all my gear used from craigslist except the chest freezer but am now still enjoying beers that are 2 month old. I only bottle beers that benefit from aging now, primarily stouts.I don't have any co2 (yet), but that could be my next investment. If it's really the amount of hops in the whirlpool and/or dry hopping that is the problem, in theory I could dial those back. My regular IPA's don't get as much oxidation.

I do plan to just dry hop once, on day 2, as Braufessor is doing. But I was planning a pretty big charge. No secondary; fill bottles straight from fermenter on day 14 and use carbonation tablets for priming sugar so I can skip the bottling bucket. Short of using co2 purges, that should introduce as little oxygen as possible I would think...

Good Luck

jakturner

Well-Known Member

A little off topic, but for those brewing Bruts is the turn around time about the same as this NEIPA? I usually crank these out in 9-10 days (with floating dip tube)

If bottling straight from the fermenter I could see that. I think most are racking to a bottling bucket which is where things go southi think someone bottle conditioned using co2 purges and had some success

Couldn’t one monitor their gravity and bottle with a few points left? I know it would be tricky, but maybe use the plastic bottles. Would eliminate the bottling bucket and that transfer.

ryanm8

Well-Known Member

Purge with CO2 and bottle from the fermenter and you will be fine.

Northern_Brewer

British - apparently some US company stole my name

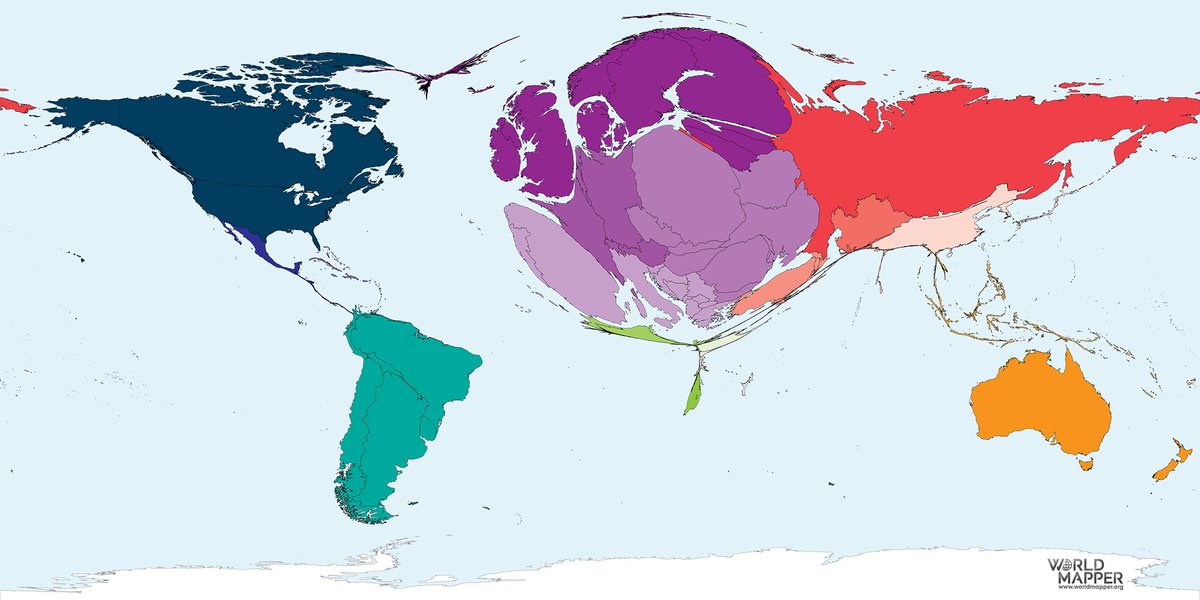

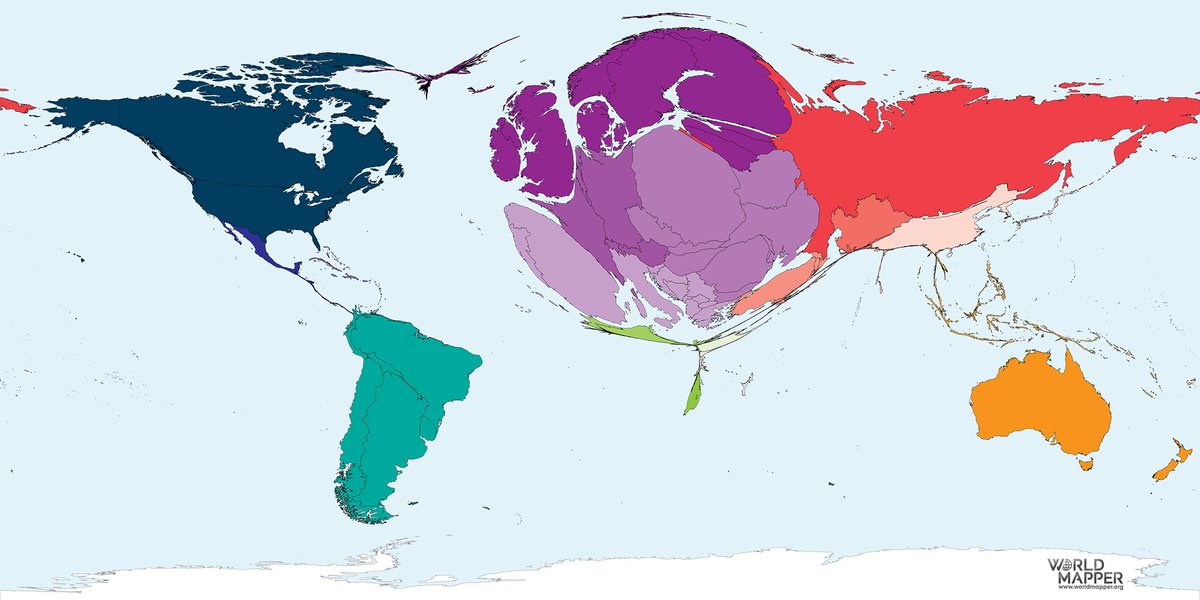

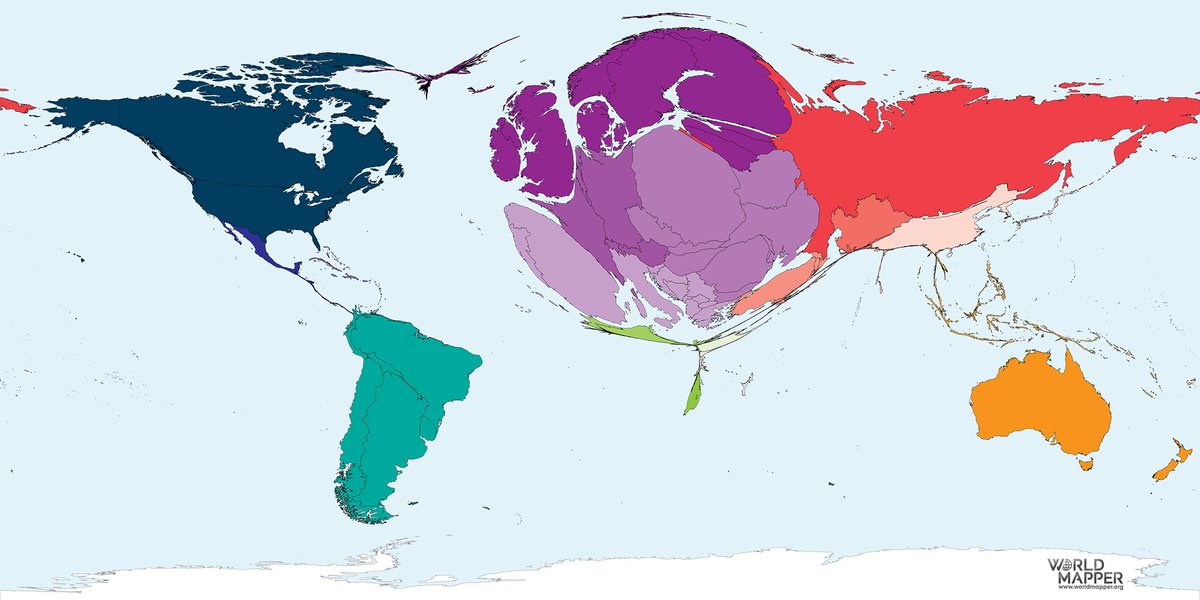

I know it's kinda OT, but I saw this cartogram of where oats are grown, and figured you guys would enjoy it - sadly I don't know who made it :

Zealous61

Active Member

- Joined

- Mar 2, 2018

- Messages

- 31

- Reaction score

- 13

If I was your mail man, that would have been taxed.

Oh man. I saw someone else quote you on that without context. I was hoping you hadn't posted a photo of your wife or something, LOL.

I don't get itI know it's kinda OT, but I saw this cartogram of where oats are grown, and figured you guys would enjoy it - sadly I don't know who made it :

I don't get it

That’s good, because it’s not a joke.

Northern_Brewer

British - apparently some US company stole my name

I don't get it

It's just for interest, given the prominence of oats in this style. It's a pity that I don't know where it came from but presumably the area of each country depicts its total oats crop (ie UK produces a lot, Africa very little) and the intensity of the colour is presumably some kind of density measure (ie India produces quite a lot, but it's such a massive country that oats are a fairly small proportion of its farming output).

I didn't think it was a joke, I meant to relate that I didn't understand it. I would guess you didn't either.That’s good, because it’s not a joke.

This is what I found on the internet as of 2015 for global oat production, I fail to see what this has to do with anything regarding brewing Northeast style IPAsIt's just for interest, given the prominence of oats in this style. It's a pity that I don't know where it came from but presumably the area of each country depicts its total oats crop (ie UK produces a lot, Africa very little) and the intensity of the colour is presumably some kind of density measure (ie India produces quite a lot, but it's such a massive country that oats are a fairly small proportion of its farming output).

1. Russia (5,991K Tonnes)

2. Canada (3,303K Tonnes)

3. Poland (1,363K Tonnes)

4. Australia (1,205K Tonnes)

5. Finland (1,069K Tonnes)

6. United States (1,014K Tonnes)

7. United Kingdom (997K Tonnes)

8. Chile (739K Tonnes)

9. Spain (729K Tonnes)

10. Sweden (684K Tonnes)

LoneTreeFarms

Well-Known Member

My life right now.

I didn't think it was a joke, I meant to relate that I didn't understand it. I would guess you didn't either.

it's a map where countries are re-sized based on their production of oats relative to others. that's it.

No doubt.... at least the outlook has some sunshine in it for a change. Been a ****** few weeks.View attachment 592380

My life right now.