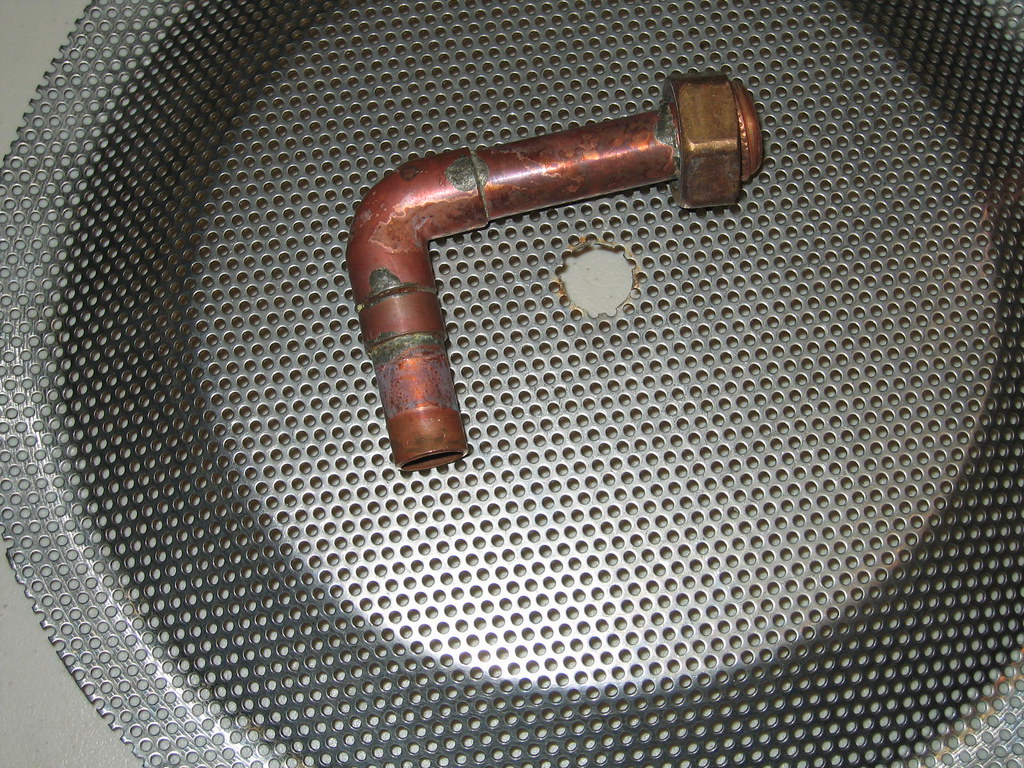

So I have my converted keggle, bulkhead and fittings, and now my false bottom and dip tube. first of all Im *pumped* to get this stuff together and in use, but I want to make sure I install correctly.

My main concern is how do you guys get the false bottom out once you have the dip tube through? Do you just turn the dip tube counter clockwise? do you push down on the false bottom until the dip tube comes out?

How far is your dip tube from actually touchign down in the center of your keggle/kettle? I was thinking low as possible.

I'm assuming you use a metal bit to drill a hole in the FB?

Any other considerations? I'd like this to be easy to take apart/clean.

My main concern is how do you guys get the false bottom out once you have the dip tube through? Do you just turn the dip tube counter clockwise? do you push down on the false bottom until the dip tube comes out?

How far is your dip tube from actually touchign down in the center of your keggle/kettle? I was thinking low as possible.

I'm assuming you use a metal bit to drill a hole in the FB?

Any other considerations? I'd like this to be easy to take apart/clean.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)