I need a little help - I'm coming to my wit's end.

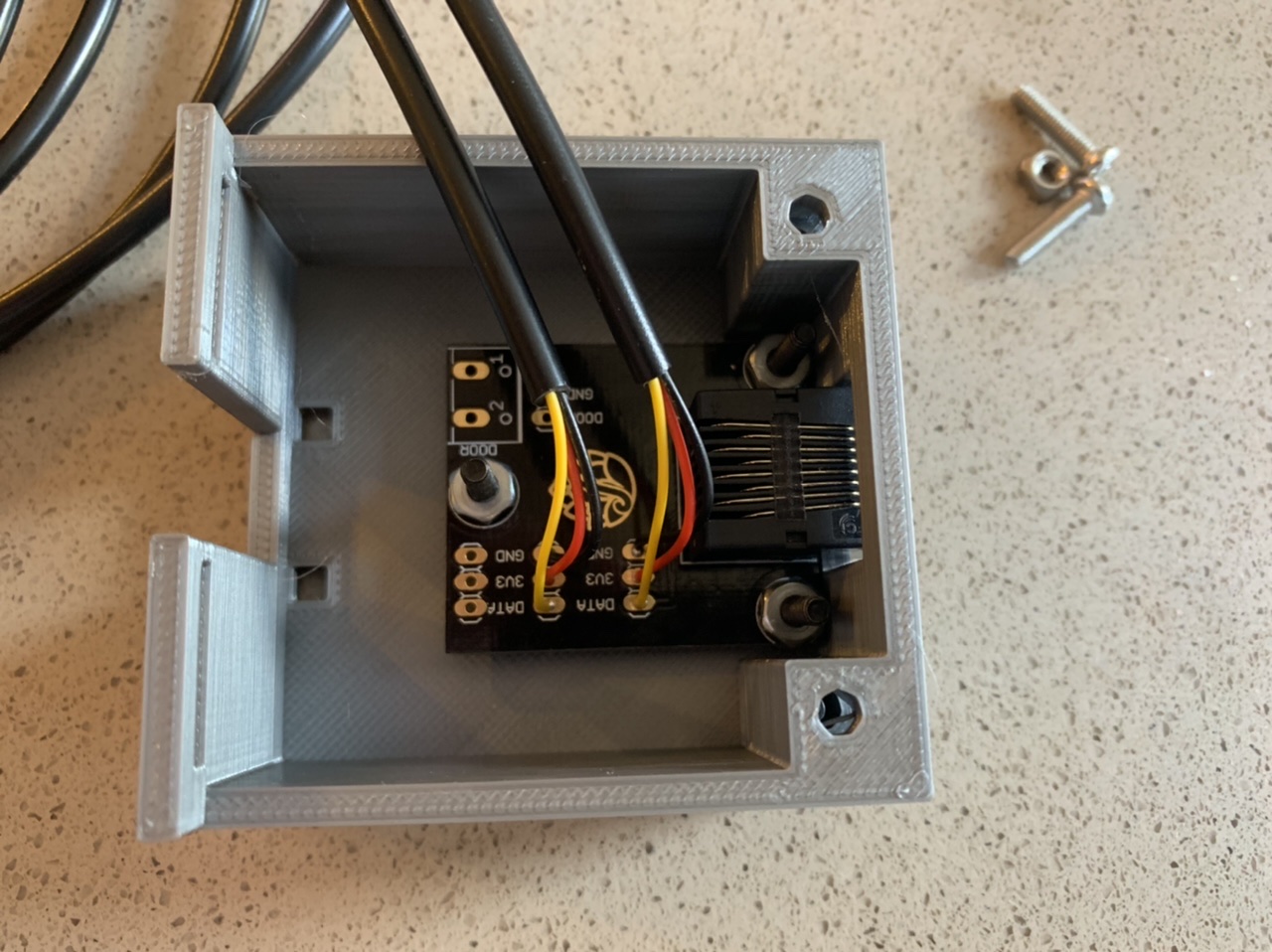

I built myself a little controller box with a power supply and relay board and it worked great once. The second time I used it, it blew the 5A fuse in the power switch (this little guy: URBEST Inlet Module Plug 5A Fuse Switch Male Power Socket 10A 250V 3 Pin IEC320 C14

https://www.amazon.com/dp/B00ME5YAPK/ref=cm_sw_r_cp_apa_i_RPwIDbDV5KTST )

I swapped out the fuse and the fermentation continued on without a hiccup.

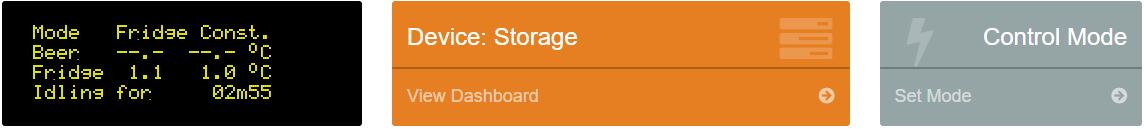

I started another ferment on Saturday night around 6:00pm. Things were going great until this morning around 9:00am when I checked fermentrack and saw that it had lost connection to the controller. When I got home, I found that the fuse had blown again.

What could be causing the fuse to blow?

I did have some foam come up through the airlock and some liquid made its way down into the thermocouple. Could the temp probe have shorted out?

I'm stumped. Unless itsi the cycling of the relays, I can't think of what could be drawing more than 5 Amps.

Should I just get a slow-blow fuse and see if the problem goes away?

Thanks!

This is the power supply I'm using:

5V Power Supply,PHEVOS 5v 5A Dc Universal Switching Power Supply for Raspberry PI Models,CCTV, Radio, Computer Project,LED Strips Pixel Lights (5V5A)

https://www.amazon.com/dp/B07B111B7Y/ref=cm_sw_r_cp_apa_i_N6wIDb20A8GPD

And the relay board:

SainSmart 2-Channel Relay Module

https://www.amazon.com/dp/B0057OC6D8/ref=cm_sw_r_cp_apa_i_57wIDbFEV8Q0Q

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)