Re: single 5V power source for ESP8266 and relay rack #9

Jan 14, 2019, 02:42 am

Quote from: DaleSchultz on Jan 13, 2019, 11:38 pm

Quote from: DaleSchultz on Jan 13, 2019, 11:38 pm

I did in fact already connect the VCC next to the in pins to the 3V3 of the NodeMCU and I also bound all grounds together and it seemed to work. Since only one power supply is in play, I thought that all the grounds should be at the same level anyway, no?

Ah Here's the trick.

You presently have the mind-set of doing your house wiring. You connect one thing to another with a wire, the current flows, the light goes on. What's the problem?

Well, we are not doing your house wiring here!

We are working with parts which operate at 16 MHz, that is Radio Frequency and a piece of wire is an antenna capable of receiving and transmitting signals. It is an inductor, albeit small.

Again and again here, we see the problems when someone innocently connects one of these relay boards to an Arduino of sorts (because of course, this is the Arduino forum), writes their code, the relays click in step and the indicator LEDs light, but then they connect the relays to their power devices and suddenly and unexpectedly the code starts crashing.

What happened?

Well, the relays switching generate rapid transients - current impulses in the wiring which are transmitted inductively from one part of the wiring to another where there are small voltage drops across the wires.

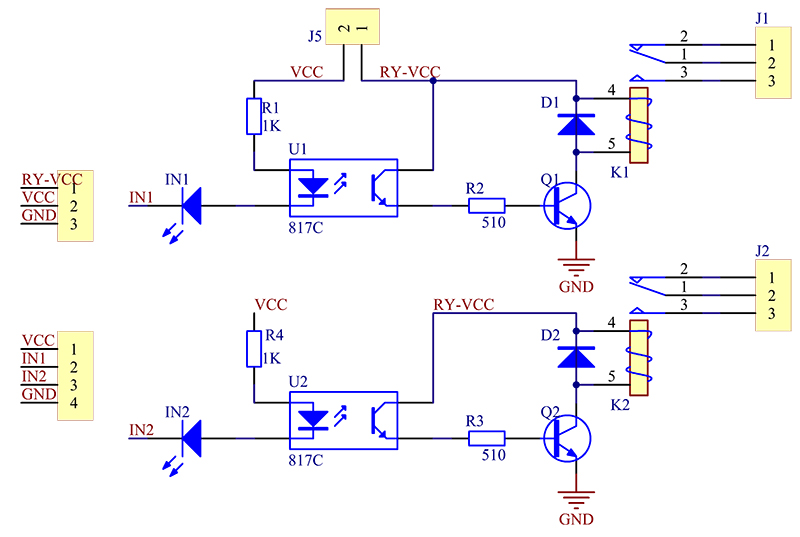

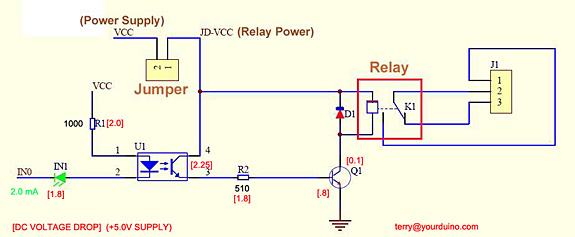

To avoid this, the relay board provides some optical isolation, but to actually make use of this, it is necessary to actually keep the input circuit to the Arduino/ NodeMCU separate from that carrying the relay current, and to prevent inductive pick-up from one to the other.

Quote from: DaleSchultz on Jan 13, 2019, 11:38 pm

If I connect +5V to the VCC next to the IN pins as you suggest, then surely I am driving 5V onto the NodeMCU pins in one of the two states (HIGH/LOW)?

Ah! That is a different matter, I was waiting for you to ask.

You will note that on the relay board, there is an indicator LED in series with each opto-coupler. Each of these has a voltage drop and will not conduct at all below a certain voltage. If we figure that of the opto-coupler as 1.2 V and the indicator as 2 V, the total voltage threshold is about 3.2 V or so - there is very little leeway left to control this with a 3.3 V signal. So connecting the "Vcc" to 3.3 V is likely to be quite unreliable - it may work now, but mysteriously fail later.

By connecting it instead to 5 V at the NodeMCU itself, it will be actuated properly at 5 V when a LOW is sent, but due to the 3.2 V threshold, the pin will never be pulled higher than 2 V, so there is no risk to the NodeMCU.

Quote from: DaleSchultz on Jan 13, 2019, 11:38 pm

I am a bit confused by this "(by another twin cable separate from the relay power supply)"

We are talking a single connection (VCC to +5V), so why twin?

If that VCC is connected to VIN of the NodeMCU and VIN is also connected to VCC supplying the coil power, how is that any different to connecting the two VCC pins directly?

"Twin" means that the Power and ground wires must run together as either a "figure eight" cable or simply twisted, so that they do not form a loop which can either pick up or radiate impulses by induction. And to avoid impulses appearing along the resistance and inductance of the wiring, there needs to be a twin cable from relay board to power supply (where the reservoir capacitor is) and another separately from NodeMCU to power supply.

Quote from: DaleSchultz on Jan 13, 2019, 11:38 pm

What is the reason to NOT connect ground of NodeMCU to GND of the relay board?

To maintain isolation as described.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)