TerapinChef

Well-Known Member

I see a huge rush in used-stationary-bike-sales in the United States, now's the time to corner the market...

I see a huge rush in used-stationary-bike-sales in the United States, now's the time to corner the market...

Yes pics please. Mine wobbles a lot too. The uneven grind is annoying.

I'll try to get them tonight after the daughters guitar recital.

Replaced the cotter pin on my Corona last night! used a 8-32 1 1/2" long nut and bolt. WOW what a difference. Never realized how far out my plates really where.

Thought I messed something up when I put it back together. lol plates are really close and adjustment is slight (always had a lot of play in adjustment since plate was so loose and out of parallel). Added an extra washer to sides (up to 4) and played with the main adjustment. I think this will finally work the way it was "supposed to". Might have a question on how to adjust a properly set up corona, I have no idea now!

Right now It sounds like the teeth on the plates are just hitting slight "ting" as the plates rotate. Can't get it any looser though. Can go tighter, all the way down to unable to turn.

Never saw one that wasn't like this from the factory. So I thought it was meant to be that way! lol. Some Quality Control in ol Mexico!

Might explain my first partial mashing disaster.

Excellent thread with awesome info! thanks again.

I'm giving up on the Corona Mill already. It sounds like too much work. I'm going to figure out how to turn one of my pasta rollers into a grain mill.

Yesa I was all on board, now all this new info..hmmm

I tried to get my cotter pin out last night, but couldn't with the tools I had handy. I was considering the jb weld idea.

Can you take a pic of yours with the bolt on?

I just started listening to Craftbrewer Radio podcasts out of Australia, and went to the website today. The first article I dug up in the equipment section is all about the Corona mill....

Corona Grain Mills

I'm still in the process of reading it, but it is VERY corona positive...

Anyone got some older brewing books that would have such a section in there? I would love to read it.

Here's my simple set up. improved with the bolt.

ImageBam - Fast, Free Image Hosting and Photo Sharing

ImageBam - Fast, Free Image Hosting and Photo Sharing

ImageBam - Fast, Free Image Hosting and Photo Sharing

...

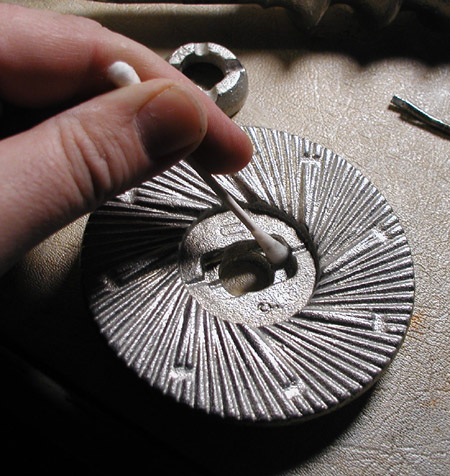

And with the cotter pin pulled and disassembled. The 3 pieces are the auger, the grinding plate, and the collar which seats the plate on the auger.

...

I still didn't get a chance to take pics of mine, so I'll use yours.

On the collar was one pair of recesses shallower than the other? All I really had to do on mine was pull the cotter pin, rotate the collar 90 degrees and reinsert the cotter pin using the shallower set of indents on the collar. The pin was quite snug and the plate became virtually wobble free. It is possible that my cotter pin was a slightly larger diameter as well, it is hard to tell from the pics.

Oh, and mine is a Corona knockoff branded "Victoria" but I hear they are made in the same factory.

As far as a name for your creation, Looks like a Choo - Choo to me.... Run with it.

Ok, I do not have pictures yet but I definitely win the prize for the ugliest, rube goldbergiest, corona mill contraption.

I tried to just hit it up with a drill. That was hilarious. There was a four foot cyclone of grain spraying across my basement.

To the drawing board. I found some dryer ductwork, you know that circular telescoping stuff. and did surgery on it until it formed a baffle around the whole milling section. Then I used a 2 foot section to serve at the hopper. (The hopper holds 4+ pounds.

Ugly as all get out. I mean it. But I could not believe how well it worked. The grind came out very nice. I did 10 pounds in maybe 2 minutes. I got 79% efficiency on my first batch with it.

I so can't wait to see pics.

I blew out one of my 3 gallon water bottle fermenters last weekend and ahve been thinking about using a section as a big baffle over the front end...trouble is it may lose it's train like look...Unless I paint it red.

Ok, I do not have pictures yet but I definitely win the prize for the ugliest, rube goldbergiest, corona mill contraption.

I tried to just hit it up with a drill. That was hilarious. There was a four foot cyclone of grain spraying across my basement.

To the drawing board. I found some dryer ductwork, you know that circular telescoping stuff. and did surgery on it until it formed a baffle around the whole milling section. Then I used a 2 foot section to serve at the hopper. (The hopper holds 4+ pounds.

Ugly as all get out. I mean it. But I could not believe how well it worked. The grind came out very nice. I did 10 pounds in maybe 2 minutes. I got 79% efficiency on my first batch with it.

I so can't wait to see pics.

I blew out one of my 3 gallon water bottle fermenters last weekend and ahve been thinking about using a section as a big baffle over the front end...trouble is it may lose it's train like look...Unless I paint it red.