It isn't anything most of you haven't seen before - but a slightly different implementation:

Untitled by brewerJP, on Flickr

Untitled by brewerJP, on Flickr

Untitled by brewerJP, on Flickr

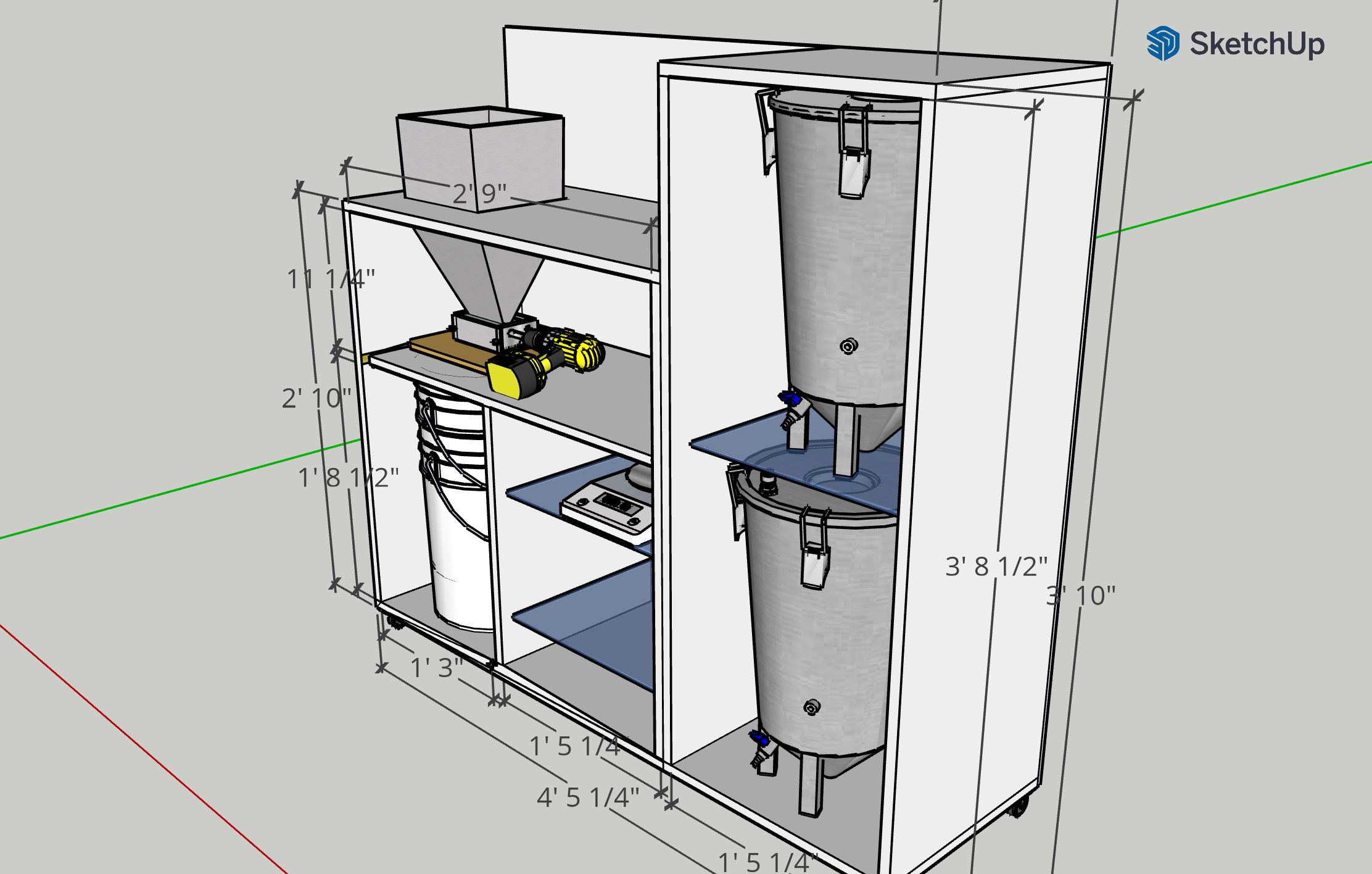

Basically I wanted to keep the top surface minus where the hopper comes through clear so that I could use it for something else - like a stir place for example. Inside on the left I'll have my 5-gallon bucket (have to build a riser for it to get it closer to the mill output) and on the right side I'll probably put a couple shelves in for storing things like my grain scale. I finished the front off with a bronzed plexiglass for no other reason than I that's the way I wanted it to look The side has a stainless steel standard sized blank switch plate that I've made a cut of for a IEC power connector - and I'll drill a hole for a DPDT center-off switch (obviously only half used - RadioCrap didn't have SPDT switches I liked). The entire shelf that supports the mill and motor is easily removable so I can work on it outside the cabinet.

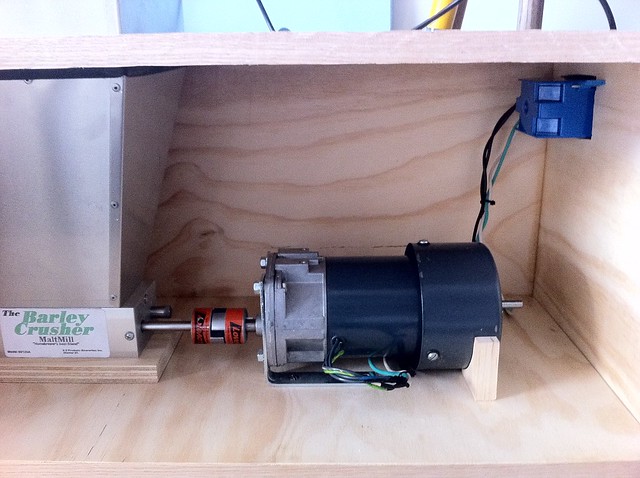

The side has a stainless steel standard sized blank switch plate that I've made a cut of for a IEC power connector - and I'll drill a hole for a DPDT center-off switch (obviously only half used - RadioCrap didn't have SPDT switches I liked). The entire shelf that supports the mill and motor is easily removable so I can work on it outside the cabinet.

The mill is a Barley Crusher with the 15lb hopper - with the LoveJoy spider and couplings and finally the ubiquitous-standard motor from Surplus Center.

Ideas on how to finish the cabinet off!?

Untitled by brewerJP, on Flickr

Untitled by brewerJP, on Flickr

Untitled by brewerJP, on Flickr

Basically I wanted to keep the top surface minus where the hopper comes through clear so that I could use it for something else - like a stir place for example. Inside on the left I'll have my 5-gallon bucket (have to build a riser for it to get it closer to the mill output) and on the right side I'll probably put a couple shelves in for storing things like my grain scale. I finished the front off with a bronzed plexiglass for no other reason than I that's the way I wanted it to look

The mill is a Barley Crusher with the 15lb hopper - with the LoveJoy spider and couplings and finally the ubiquitous-standard motor from Surplus Center.

Ideas on how to finish the cabinet off!?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)