You have my vote.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My Ugly Junk- Corona Mill Station...

- Thread starter Revvy

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

wilserbrewer

BIAB Expert Tailor

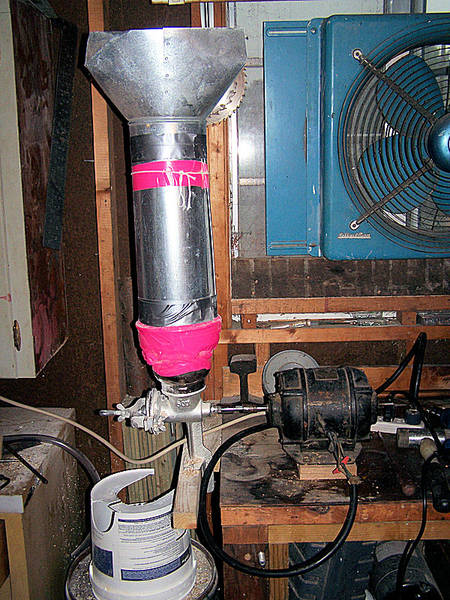

+ 1, my vote is in! I love how I can see some bare copper wire under the top wire nut. The RR track anvil is a nice bench adornment, the cut bucket grain deflector looks to be "early" Biermuncheresque. The stained patina of the work bench reminds me of my own, and w/ all that deflected spare grain laying about, the neighborhood mice are as happy as the butcher's dog.

I'd be tempted to let that grinder motor go full on just to see how quickly you could empty the hopper.

I'd be tempted to let that grinder motor go full on just to see how quickly you could empty the hopper.

Laughing_Gnome_Invisible

Well-Known Member

- Joined

- Jan 4, 2008

- Messages

- 12,262

- Reaction score

- 734

You spotted the RR track/anvil. I'm weeping with pride!

wilserbrewer

BIAB Expert Tailor

Yea Gnome, just be sure to keep your sweaty palms away from that dodgy grinder while its energized, we do want you around another day to keep us entertained!

LakeErieBrew

Well-Known Member

Holy hell, that's an quite an abomination Gnome. I love the pink tape and exposed wiring. It's like modern art.

Laughing_Gnome_Invisible

Well-Known Member

- Joined

- Jan 4, 2008

- Messages

- 12,262

- Reaction score

- 734

Holy hell, that's an quite an abomination Gnome. I love the pink tape and exposed wiring. It's like modern art.

You missed the string around the top at the same level as the duct tape. It is tethered to the wall with string. Without the string it all falls over when it has 10 ponds of grain in it.

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

wilserbrewer

BIAB Expert Tailor

I saw the string! Didn't realize that it tethers the stack...duly noted w/ additional points added.

LakeErieBrew

Well-Known Member

+10 cool points for the string tied to the wall!

Laughing_Gnome_Invisible

Well-Known Member

- Joined

- Jan 4, 2008

- Messages

- 12,262

- Reaction score

- 734

OK. I'm off to make a build page for the wiki. I would hate to think that new brewers might not know how to electrocute and/or dismember themselves in style.

Gnomy, you won long ago purely by merit of the hot pink duct tape...but this takes ugly junk to the highest level possible....Methinks, you have dethroned king biermuncher himself for who deserves to wear the "My junk is ugly" crown.....

Laughing_Gnome_Invisible

Well-Known Member

- Joined

- Jan 4, 2008

- Messages

- 12,262

- Reaction score

- 734

Gnomy, you won long ago purely by merit of the hot pink duct tape...but this takes ugly junk to the highest level possible....Methinks, you have dethroned king biermuncher himself for who deserves to wear the "My junk is ugly" crown.....

I want a certificate!

wilserbrewer

BIAB Expert Tailor

Anything I can do to make it uglier?

I'm thinking a third ribbon of pink duct tape at the top of the hopper, two or three good wraps folded back over could extend the hopper another inch or two for increased capacity. It would finish it off sort of like the cherry on a sundae. What the hell, that pink tape was gararge sale priced anyways right.

aeonderdonk

Well-Known Member

I'm definitely going to build one of these with a victoria mill from discount tommy using the style of wilserbrewer.

camiller

Well-Known Member

Hey wilserbrewer you might want to use this link:

https://www.homebrewtalk.com/1308996-post144.html

in your sig rather than

www.homebrewtalk.com/f51/my-ugly-junk-corona-mill-station-90849/index15.html

Your current link assumes the person clicking it has left the default number of posts per page set to the forum default and your linking to page 15, but I have it set to 40 posts per page so your post is on page 4. Following your link just takes me to the top of page 5. The link I put above takes a person following it straight to your post.

https://www.homebrewtalk.com/1308996-post144.html

in your sig rather than

www.homebrewtalk.com/f51/my-ugly-junk-corona-mill-station-90849/index15.html

Your current link assumes the person clicking it has left the default number of posts per page set to the forum default and your linking to page 15, but I have it set to 40 posts per page so your post is on page 4. Following your link just takes me to the top of page 5. The link I put above takes a person following it straight to your post.

secinarot

Well-Known Member

I need to see a picture to understand what you're saying. I can't see how you would need that many washer to make it work.

Here is a picture of my mill (hope it posts OK). You can see how the bracket doesn't meet with the body of the mill. The end of the auger shaft does not sit in the bracket all the way. The main problem is the ball bearing in the bracket where the adjusting screw is prevents it from going in all the way.

Here is a picture of my mill (hope it posts OK). You can see how the bracket doesn't meet with the body of the mill. The end of the auger shaft does not sit in the bracket all the way. The main problem is the ball bearing in the bracket where the adjusting screw is prevents it from going in all the way.

For some bizarre reason it didn't post.....

Let me try...

That looks exactly like all of our mills...I'm still confused...it they don't meet, then just put your spacer washers on the left and right where the wing nuts are...put enough in there to create a gap between the front grinder and the rear plate....

secinarot

Well-Known Member

Do you have a ball bearing in the chamber where the tip of the auger shaft fits into the bracket? That is what's preventing the ends from meeting in mine. When I look at some of the other photos, it looks like the auger shaft slides into that chamber all the way up to the cotter pin that holds it in pace. However with mine it doesn't go in all the way. In any event, I put a couple of large nuts to fill the gaps on each side of the bracket and I can adjust the grinding plates just fine. It looks ugly but then again isn't that the title of this post?That looks exactly like all of our mills...I'm still confused...it they don't meet, then just put your spacer washers on the left and right where the wing nuts are...put enough in there to create a gap between the front grinder and the rear plate....

wilserbrewer

BIAB Expert Tailor

secinarot,

Just guessing again here, but I am inclined to think that the ball bearing in your front bracket is binding and is not all the way inserted into the front bracket. I would try and press the bearing fully into the bracket by tapping lightly w/ a punch and hammer, or just by simply tightening the two outer bolts to force the bearing home. I'm guessing that during manufacturing and assembly of your mill, the bearing was not full placed in the front bracket of the mill.

Give it a little wack and reporrt back.

Just guessing again here, but I am inclined to think that the ball bearing in your front bracket is binding and is not all the way inserted into the front bracket. I would try and press the bearing fully into the bracket by tapping lightly w/ a punch and hammer, or just by simply tightening the two outer bolts to force the bearing home. I'm guessing that during manufacturing and assembly of your mill, the bearing was not full placed in the front bracket of the mill.

Give it a little wack and reporrt back.

Synovia

Well-Known Member

I'm definitely going to build one of these with a victoria mill from discount tommy using the style of wilserbrewer.

Anyone know where else to get these cheap? DiscountTommy went from 15.95 + $8 shipping yesterday to $39.95 each

rico567

Well-Known Member

Anyone know where else to get these cheap? DiscountTommy went from 15.95 + $8 shipping yesterday to $39.95 each

Well, my purchase from "Tommy" went something like this:

Week before last, someone on this forum said they got it for $16 + $8. That rang my bell, because I'm not paying $50 for a Corona mill. I go to the link, and they're no longer available for that ; $20 + $8.

But- there's a "make and offer" button there, so.....I offer $16 + $8. The next day, I get an e-mail rejecting the offer.

Then- the day after that, I get an e-mail from Flea Bay, click on the link and go back, and it's back to $16 + $8!

I bought it, of course, and went back the next day out of morbid curiosity, and 'ol "Tommy" was back up to $20 + $8. Obviously, his pricing is just on a yo-yo that has nothing to do with his actual cost on these things.

Anyway, I've got the mill, and now we'll see what kind of Ugly Junk Award I can win....

secinarot

Well-Known Member

secinarot,

Just guessing again here, but I am inclined to think that the ball bearing in your front bracket is binding and is not all the way inserted into the front bracket. I would try and press the bearing fully into the bracket by tapping lightly w/ a punch and hammer, or just by simply tightening the two outer bolts to force the bearing home. I'm guessing that during manufacturing and assembly of your mill, the bearing was not full placed in the front bracket of the mill.

Give it a little wack and reporrt back.

I checked the ball bearing and it's in there tight. I even removed the bearing to see if would fit flush and it didn't. I've tried everything I can think of and there is no way that bracket is going to fit flush - the arms are just too short. I really think I have mismatched parts. I can't imagine that the place that makes these has too much quality control. They probably just threw a bunch of parts together as long as they kind of fit. Not worth me sending it back so I'll just tinker with it and I'm sure I can get it to work fine with some spacers.

wilserbrewer

BIAB Expert Tailor

Bummer man...i would get on discount tommy and tell him you want a replacement. His ad clearly states "satisfaction" and "gaurantee". Tell him you want another shipped out, and he can pay the return freight, or you can keep the parts that don't fit together right.

Don't live w/ it...these cheap mills don't need any additional challenge.

Don't live w/ it...these cheap mills don't need any additional challenge.

secinarot

Well-Known Member

I emailed Discount Tommy and sent them a picture of the grinder showing the gap in the bracket. This is their response: "Looking at your pictures it looks like all of our other grinders. I do no see a problem with the grinder. "

So, buyer beware if you plan to buy one of these from Discount Tommy. Seeing that I got it for $24 shipped, I'm just going to add a couple of spacers and live with it. I think at that price it's still a good deal. However if you have to pay more to get this model that doesn't fit together right, I would look elsewhere.

So, buyer beware if you plan to buy one of these from Discount Tommy. Seeing that I got it for $24 shipped, I'm just going to add a couple of spacers and live with it. I think at that price it's still a good deal. However if you have to pay more to get this model that doesn't fit together right, I would look elsewhere.

rico567

Well-Known Member

Well.....maybe not quite, but here it is anyway.... I am taking it as an article of faith that all these attachements will post. Anyway, take a look at that crush! Ugly it may be, but crush it does.

secinarot

Well-Known Member

I just bought a corona mill and have never crushed my own grains before. Looking at your last picture showing the crush, it looks like I want to see the empty husks somewhat in tact and then the insides of the grains sort of chopped up. Is that true?

Well.....maybe not quite, but here it is anyway.... I am taking it as an article of faith that all these attachements will post. Anyway, take a look at that crush! Ugly it may be, but crush it does.

I gotta say, these Internal bucket designs like you have are the way to go, especially since space is an issue for me. Looks like I'm going to have to re-design mine like that....that way I can store it away really easily.

So how do you mount the wood shelf to the buckt? How far down do you have it?

wilserbrewer

BIAB Expert Tailor

.... I want to see the empty husks somewhat in tact and then the insides of the grains sort of chopped up. ..

Pretty much what you want, all grains fractured w/ the interior portion available to the mash. NO WHOLE GRAINS!

here is a good link regarding evaluating the crush....https://www.homebrewtalk.com/wiki/index.php/Evaluating_the_Crush

IMO you could tighten up your crush a bit Rico.

Revvy, details for the internal bucket mount are in my sig, or here if you want to use the corona hopper.

https://www.homebrewtalk.com/f51/my-ugly-junk-corona-mill-station-90849/index3.html#post981526

Another plus for this system, is that you can crush your grain in advance of the brew session, and just snap a lid on the mill / bucket till you are ready to brew.

rico567

Well-Known Member

Revvy: From reading other posts about "mill-in-a-bucket" systems, I decided on a big chunk of wood, a two-by of some kind, would be best. So I just hacked out a semicircular piece of 2x6, and notched the center of the curved side so that the back of the mill would clear the bucket wall. This means you can't use the manual handle in the bucket.....but that wasn't part of the plan anyhow.

The wood had to be trimmed up a bit, because I'm lousy at carpentry, and the only way I could think of to get a good template was to use a pencil and draw around the bucket rim. I tried to make the piece of wood smaller (because the bucket tapers), and it came out pretty crude....but not more so than the Corona / Victoria mill itself. I used six #10 x 1" screws and washers to attach it to the bucket wall, and that worked fine. I'm assuming that the 5 gal. Pratt & Lambert paint bucket I used is "standard," and placed the screws 8.5" down from the rim of the bucket, which makes the top of the 2x6 piece of wood 7.75" down from the rim.

The biggest problem with the original plan is that the bucket with the drill in it tends to get stuck in a bucket that you put it in. There are several obvious ways around this, but I haven't decided on any one yet, so I just milled my first batch (EdWort's Pale Ale) into a corrugated box with a trash bag for a liner.

A nice thing about this install (although I NEVER thought it would be possible, just looking at it) is that the mill can be assembled / disassembled without taking it out of the bucket.

I used a 2" and a 4" hole saw that I had laying around to make the two 2" holes, one for the drive opening in back, and the other for a drain hole in the bottom. The drain hole might not be needed for a standard 9-11 pound grain bill, but for bigger ones, it would mean draining the grist into another container or having to stop and dump the grist one or more times. I used the 4" saw to make the larger opening in the lid, and then enlarged the opening sufficiently with a utility knife.

Bottom line is that the mount is very solid. I bought a 2.5" bolt to replace the manual crank. This is a metric bolt, .125 thread pitch, I think, but the best procedure is probably to take the thumbscrew that holds the crank in to the hardware store and match the size and thread pitch.

My drive system is just put together out of stuff I have around. I use an extended 13mm socket over the bolt, to a 3/8" drive adapter that chucks into the antique Craftsman 1/2" drill you saw in the pix.

I'm happy with the mill setup. My wort came out 13.8 Brix, which is higher than either of my two previous AG batches, both of which were done with pre-crushed grain. As you can see from the photo, the crushed grain looks as good as anything I've seen in anyone else's pix. A little flour in the bottom of the box, but very little. Wort comes out of the MLT like a firehose.

The wood had to be trimmed up a bit, because I'm lousy at carpentry, and the only way I could think of to get a good template was to use a pencil and draw around the bucket rim. I tried to make the piece of wood smaller (because the bucket tapers), and it came out pretty crude....but not more so than the Corona / Victoria mill itself. I used six #10 x 1" screws and washers to attach it to the bucket wall, and that worked fine. I'm assuming that the 5 gal. Pratt & Lambert paint bucket I used is "standard," and placed the screws 8.5" down from the rim of the bucket, which makes the top of the 2x6 piece of wood 7.75" down from the rim.

The biggest problem with the original plan is that the bucket with the drill in it tends to get stuck in a bucket that you put it in. There are several obvious ways around this, but I haven't decided on any one yet, so I just milled my first batch (EdWort's Pale Ale) into a corrugated box with a trash bag for a liner.

A nice thing about this install (although I NEVER thought it would be possible, just looking at it) is that the mill can be assembled / disassembled without taking it out of the bucket.

I used a 2" and a 4" hole saw that I had laying around to make the two 2" holes, one for the drive opening in back, and the other for a drain hole in the bottom. The drain hole might not be needed for a standard 9-11 pound grain bill, but for bigger ones, it would mean draining the grist into another container or having to stop and dump the grist one or more times. I used the 4" saw to make the larger opening in the lid, and then enlarged the opening sufficiently with a utility knife.

Bottom line is that the mount is very solid. I bought a 2.5" bolt to replace the manual crank. This is a metric bolt, .125 thread pitch, I think, but the best procedure is probably to take the thumbscrew that holds the crank in to the hardware store and match the size and thread pitch.

My drive system is just put together out of stuff I have around. I use an extended 13mm socket over the bolt, to a 3/8" drive adapter that chucks into the antique Craftsman 1/2" drill you saw in the pix.

I'm happy with the mill setup. My wort came out 13.8 Brix, which is higher than either of my two previous AG batches, both of which were done with pre-crushed grain. As you can see from the photo, the crushed grain looks as good as anything I've seen in anyone else's pix. A little flour in the bottom of the box, but very little. Wort comes out of the MLT like a firehose.

rico567

Well-Known Member

Forgot to add: Thanks, wilserbrewer, I think you may be right about the crush.

wilserbrewer

BIAB Expert Tailor

Thanks, wilserbrewer, I think you may be right about the crush.

Not really my advice, I read it here on the board...."crush till you are scared", they say. I crush a good bit finer than your pic w/ good results. These cheap mills deliver big time...talk about "return on investment"!!!

Similar threads

- Replies

- 15

- Views

- 3K

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)