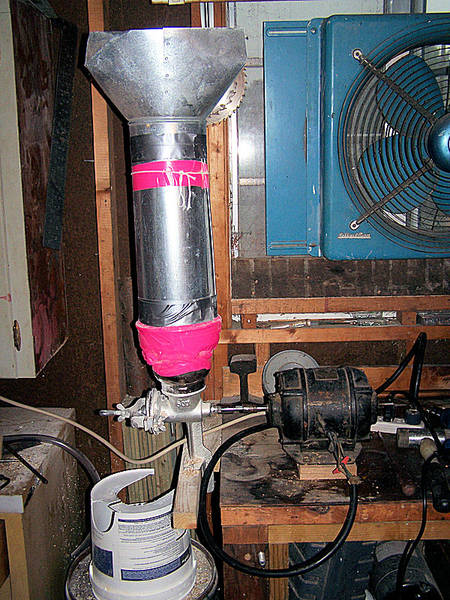

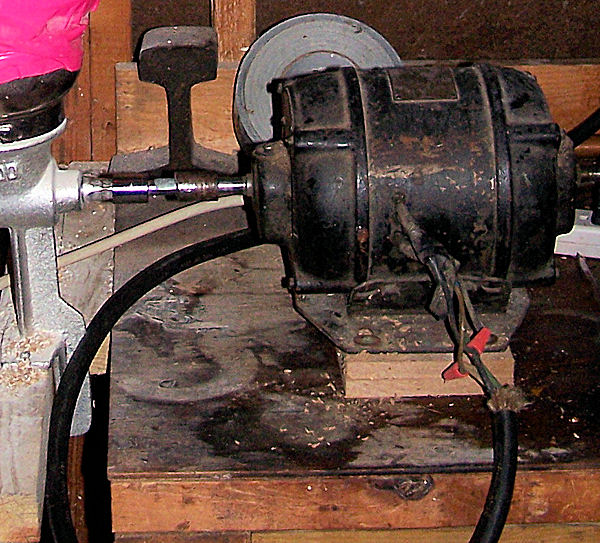

I bought one of these from that same guy on eBay... shipped fast, $22 total cost. I replaced the cotter pin with a small bolt. I still can't seem to get the plates lined up perfectly parallel. If I really tighten the nut onto the bolt (thereby fixing the plate in place firmly, no wiggle at all), the plate ends up crooked and the gap closed and opens as I turn the crank.

However, if I loosely tighten the nut, there is a little play left in the plate (less than with the cotter pin, but still some), and it seems to self align when crushing the grain (i.e. the volume of the grain moving through is enough to keep the plates aligned).

After adjusting the set screw for the gap (and adding a couple washers per this thread) , it does seem like I got about 15% flour, but nearly zero uncrushed grains, and the hulls looked mostly intact.

I crushed 1 lb. of toasted malted barley (for steeping) in my last brew. My OG was higher than expected, and I wonder if it was due to too fine a crush.

I think the setup is ok, but I think everyone here is more experienced than I am, and I'd appreciate any advice or comments.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)