Anthony_Lopez

Well-Known Member

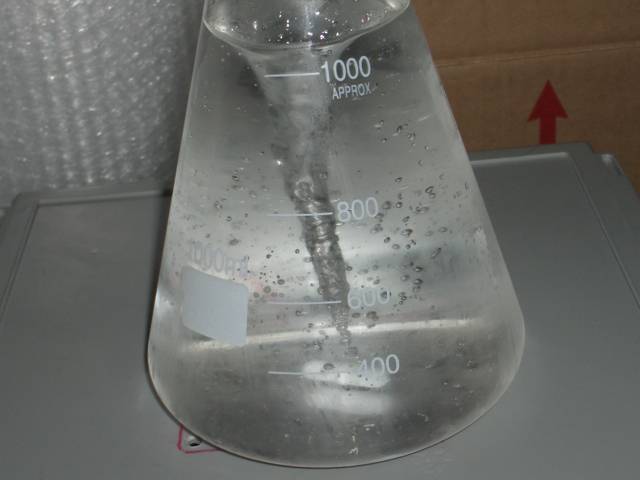

I posted a video as requested of the stirplate in action.

It's hard to say honestly. The fan is most likely a 12 VDC pulling between .5 and 2 amps of current. A 6 VDC power supply SHOULD be able to get your vortex strong if you can play around with magnet size and the distance between your fan and your flask. With my 5 VDC power supply and the correct magnet orientation, I've had no issues getting my vortex down to the base of the flask.

If you haven't altered the power supply from radioshack, you could always return it for a 12 VDC wall wort

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Very much altered. If the 6 volt doesn't do it, I'll look around the house and see if I can find something in 9v or 12 volt. And if I can't find one I'll grind my teeth and buy another 'shack adapter.

Got her figured out. When I took apart the hard-drive for the magnets, there were two. I glued only one to the fan. In a last-ditch effort, I put both magnets on the fan.

Now I have the 12 volt adapter on it running full tilt and it's not kicking the stir bar (w00t!). The vortex is all the way to the bottom and sending a crazy amount of bubbles through the water.

Maybe not, you will find a use for it.I'm a little salty about burning $15 on the 6 volt adapter that is now useless, but $30 overall for a stir plate is still about $50 in the pocket for me.

Yes, the stir bar will get thrown off to the side a lot.I guess my final question would be: can these things run too fast?

Not really, they are tough little guys.As in, so fast the stir bar would beat up the yeasties?

Yes there are 2 in each hard drive and you only use 1 of them. When the magnet is mounted on the fan if it feels like the magnetic poles are interacting with the magnets on the fan then the only way to use that fan is to put a spacer in between the fan and magnet to reduce this effect.

You will find it takes less voltage to do the same thing if a spacer is used. See above paragraph.

I never got mine to work right with the HD magnets I have (tried all combinations of 4 different magnets). I found some magnets at Hobby Lobby that are rated 10 on the 1-10 strength scale - although not as strong as the hard drive magnets. I bought the 1/2" (or so) ones, that came 3 to a pack. Put them on a metal washer tha't glues to the fan, two per side with opposite poles up. Easy to center this way, and spins the the stir bar pretty good.

I am gonna try a few different fans now to get one that spins faster, because I thing the hard drive magnets without the metal washer messed up the fan somehow.

The current set-up works, made a 900mL starter for my pale last weekend that got really thick with yeast. But, the vortex only goes down about 3" - I'd like at least 4" plus more speed if I need it.

Later,

I'm building one of these and something I discovered is that many of those old transformers (cell phone plugs or whatever your using) are not the voltage they claim they output. I've found them above and below ratings. The first one I tried claimed 10V but my multimeter said 15.4. I'm afraid I'll burn a fan with that.

Is it possible to glue the HD magnets together if the break? haha.

not sure I understand the need for the vortex to run to the bottom of the flask. All you need to do is keep the wort moving in the flask, right?

I have (3) 2L erlemyer flasks to make starters in (all I use is light DME and water) -I've been just making the starters, and agitating the hell out of the mini-wort, and pitching yeast in it, putting the airlock on and letting it sit (every day, once a day, I'd shake the flask a good couple of throws or so, and after 3 days, would draw off most of the water from the yeast cake in the flask, then shake it vigorously to get it in suspension (with what little fluid I had left in the flask) and pitch it into my newly made wort in the fermenter, and I've had good success with it. But saw this thread on DIY stir plates and figured I could get even better results with my yeast starter.

I'll definately have to try making these for my flasks.

I gave up trying on that endeavor. I also found that the HD magnets, while free, were more of a pain to deal with - trying to get them to not interfere with the fan rotation, getting them centerd/ballanced properly, etc.

I found some magnets in either the 'crafts' or 'hobbies' section of Hobby Lobby. They have several sizes that are rated a 10 (on a 1-10 scale) for strength...and they are 3.99 per pack. The large ones you get one or two magnets per pack, and the small ones you get more. I bought the medium size magnets, around 1/4" diameter, and they came six to a pack. I used four magnets for my stirplate, and they just stuck on their own to the 3 metal washer I glued to the fan.

I can try to get pics for anyone, if it is needed. But I think you'll just have to futz with your fan, magnets, and washer combinations until you getting it working. After all, that's part of the fun opf DIY, isn't it?

Hope that helps and Maerry Christmas,

Pelikan. - Thanks for the info.

So just to get it straight, you recommend a couple of days on the stir plate, with a vortex that (preferably) hits the bottom (stir-bar, anyway) and this is WITH the yeast in the wort (so I'm making these little buggers dizzy, but happy -kind of like when I hit the tap a little too much after a long week of work -a little lightheaded, but plenty happy).

Ok, well, looks like I have a nice DIY project to add to the list (next weekend, anyway). Fortunately I have a few dead 'drives that have been doing 'paper-holder' duty, and if I dig around in the closet I know I have a couple of old computer power supplies (for fans, though one of 'em may still be functional and therefore able to provide voltage for all three stirrers.... ).

Guess I'll hit NB later and order up stir bars of various sizes to figure out which works best with my rigs, and order the proper bar.

I love a project that isn't beyond my capabilities, and this one will be entirely beneficial (and probably drive the dogs a little nuts, which is usually pretty fun too -doesn't hurt to have a slightly warped sense of humor, and mine is about as warped as it gets).

Keep the yeast happy, and that makes for better beer -which is ALWAYS a laudable goal.

The main purpose of a stir plate is not so much to stir the wort, as getting the mix supersaturated with O2. In this sense, having the vortex run to the bottom is ideal, as when it hits the bottom it sends an explosion of bubbles through the wort.

From what I have been reading it's actually the opposite, that at the beginning of fermentation you should already have enough oxygen in the starter, but the yeast quickly falls out of suspension. If you have it continually stirred then the yeast will be kept in suspension and will be better able to multiply.

Check out this article. In essence, yeast need O2 to reproduce and strengthen their cell walls. The more O2 during the first 40ish hours of the culture, the more yeast you'll have -- and they'll also be healthier.

Indeed, you don't really want the yeast fermenting the starter so much as reproducing. Inevitably, the starter will be fermented to one extent or other, but the focus is reproduction and cell counts.

The rheostat will allow you to fine tune your fan speed. Hopefully that helps your setup

based upon his article I still stand by my original statement. If oxygen was the main limiting factor then injecting through an aeration system 3-6 times a day would do just as much if not more than a stir plate.

He has some really good information in that article, but he is not properly isolating variables to say that the aeration of stir plated wort is why its better and most of the time he is saying aeration/agitation.

First, this is a really good tutorial. Thank you for taking the time to make that happen.

Second, is the rheostat the only thing you are using for speed control? No other electronics? I am a typical engineer who tends to overthink and complicate everything!I don't know why I did not think of a simple rheostat on a dc fan...

Great work!

-Tripod

First, this is a really good tutorial. Thank you for taking the time to make that happen.

Second, is the rheostat the only thing you are using for speed control? No other electronics? I am a typical engineer who tends to overthink and complicate everything!I don't know why I did not think of a simple rheostat on a dc fan...

Great work!

-Tripod