Overkill

Well-Known Member

- Joined

- Oct 30, 2018

- Messages

- 57

- Reaction score

- 26

No need to reinvent the wheel!Copying me! [emoji41]

No need to reinvent the wheel!Copying me! [emoji41]

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

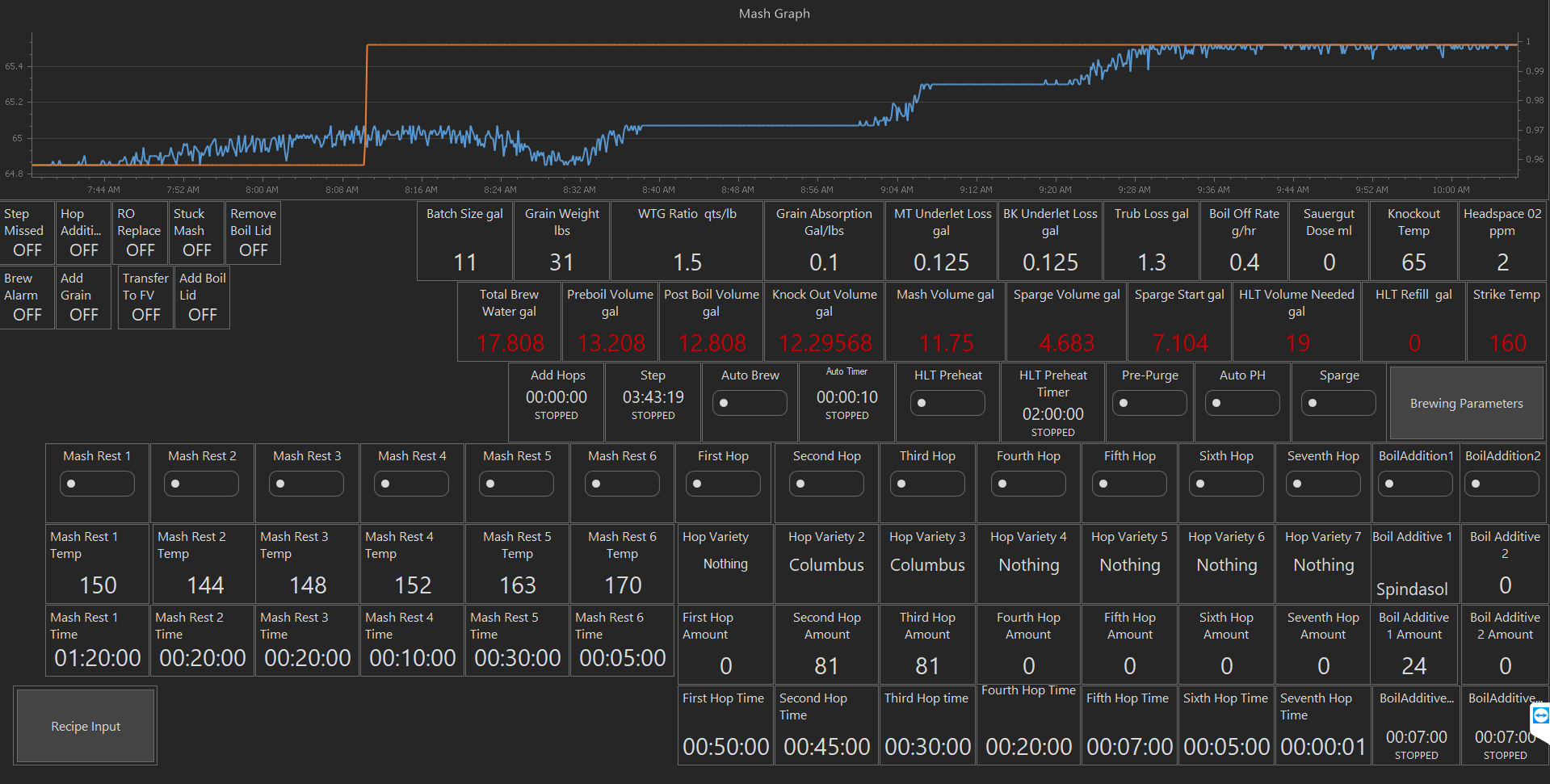

lol Id love to pay you to just design a graphic interface for my customers at the nano brewpub to see whats going on and whats on deck in fermenters and brite tanks... your graphics are amazing Die Beerery. I also wish I could display multiple screens of info at the same time which I believe Brundog is working on..

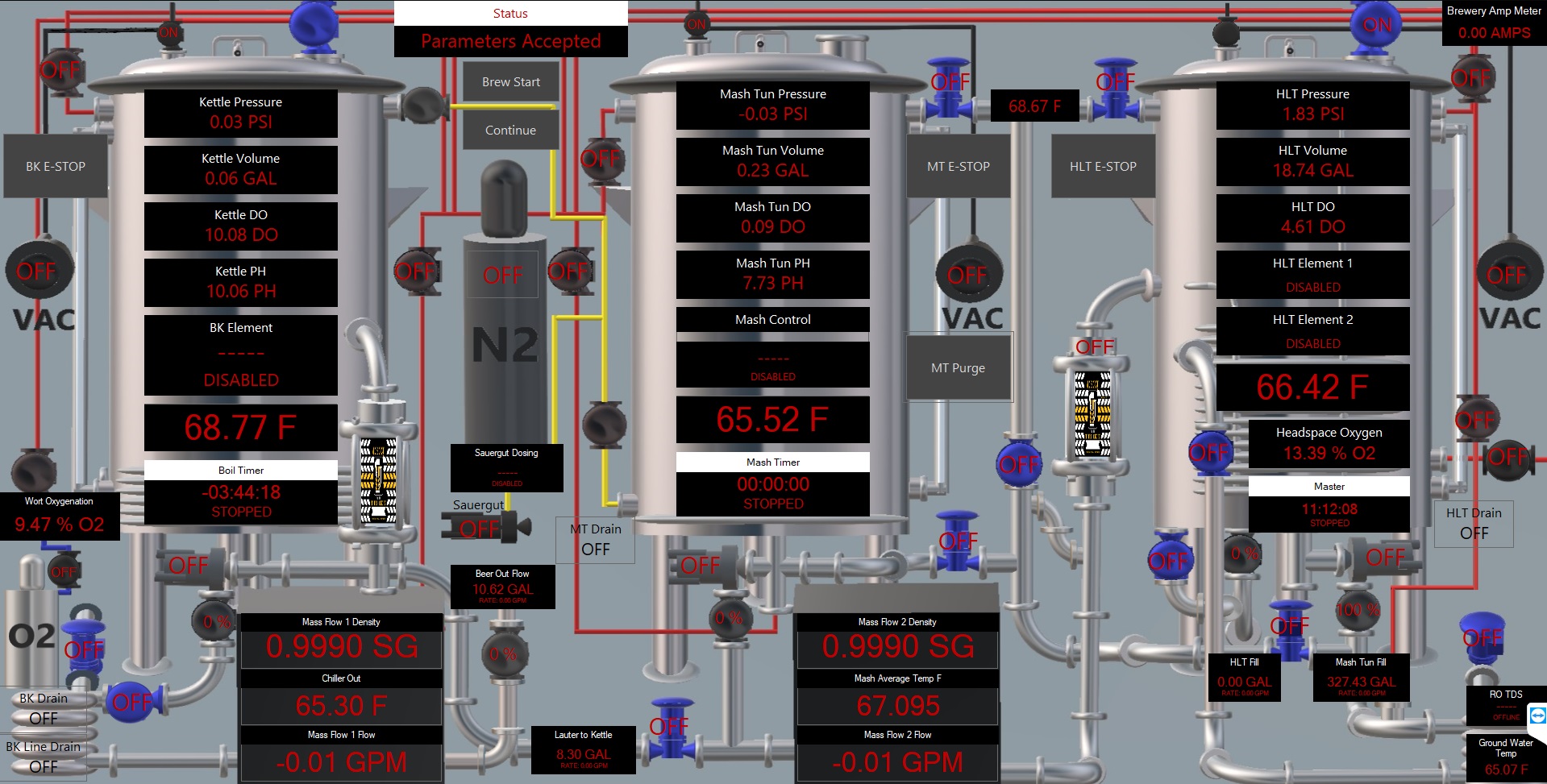

Thanks, yes I am.Hey,

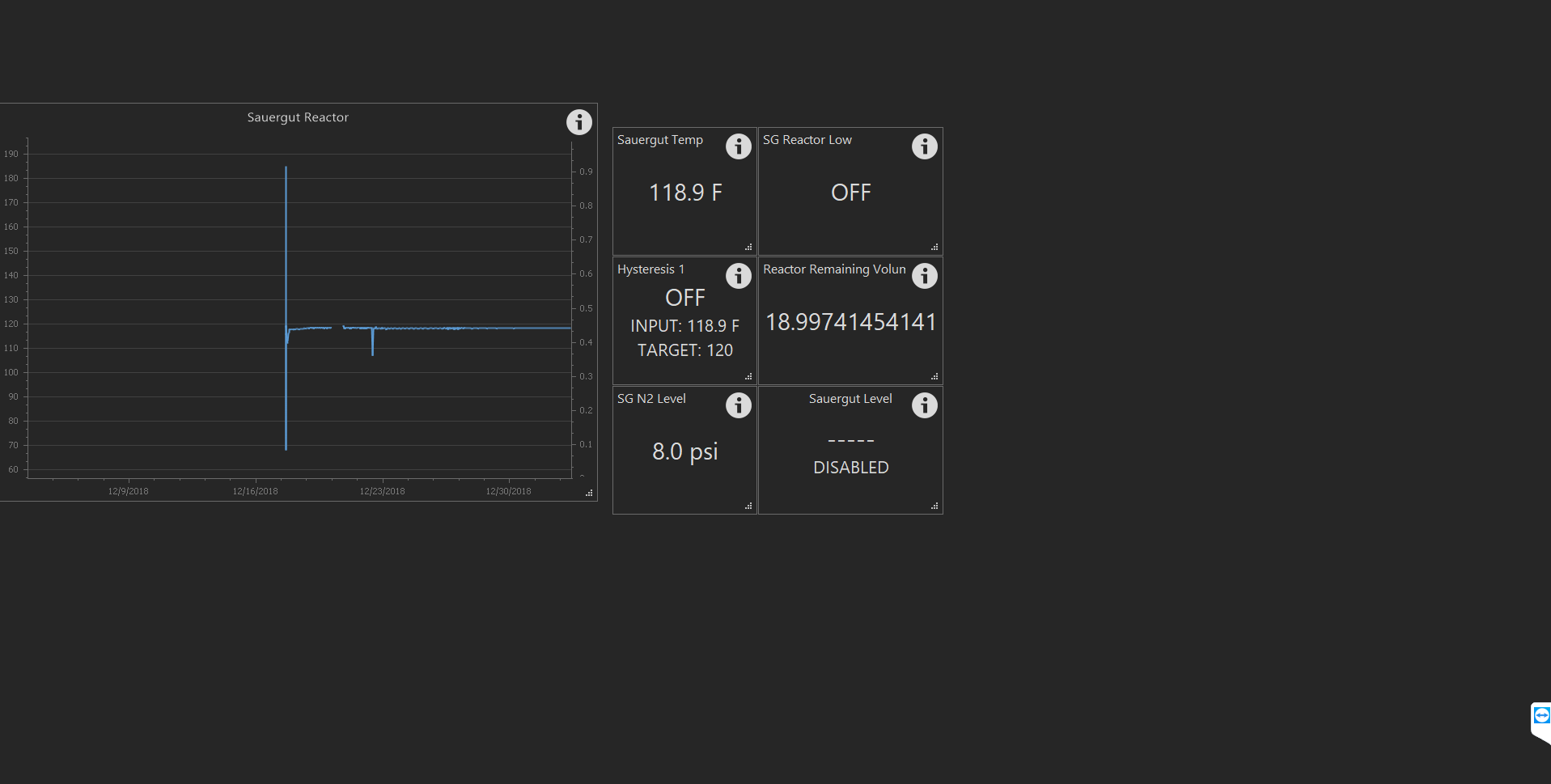

As always pretty cool stuff. So even though you are doing everything under n2, at the end you oxygenate your cold wort?

Its called LODO brewing in case you want to know more.Hey,

As always pretty cool stuff. So even though you are doing everything under n2, at the end you oxygenate your cold wort?

Do you have a link to the 1.5" solenoid valves? I've been trying to find some reasonably priced for my bottom drain.I have coming but not here yet a 1.5” tc solenoid. It is NC so when hops are called for it opens. After hop drops it closes. I do a soft boil and my steam escapes out the 3” center tc.

Do you have a link to the 1.5" solenoid valves? I've been trying to find some reasonably priced for my bottom drain.

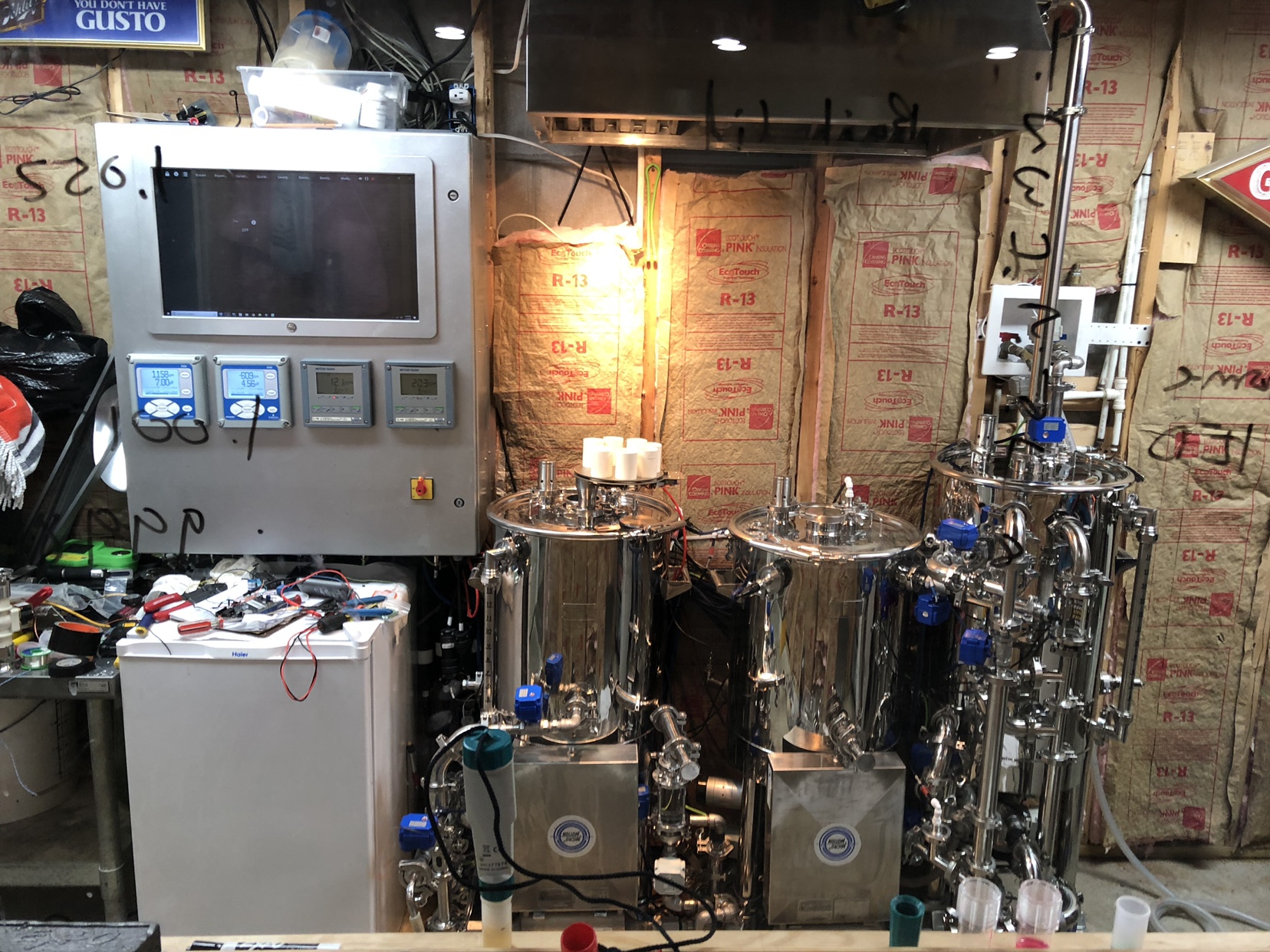

8-10 pin connections for the MFM’s, DO and PH. I removed the 10 conductor cables and soldered those outside of the panel but the rest are soldered in panel.

I have coming but not here yet a 1.5” tc solenoid. [...]

I do a soft boil and my steam escapes out the 3” center tc.

It looks like in your later pictures of your build you abandoned the 10 pin connectors for the MFMs and wired directly from the RFT9712 to the sensor. What was the reason for switching?

Of course. I expected no less

I could likely find out from one of your videos but if I might ask here are you using a condenser, or a hood?

The condenser thing has its attractions though there's a potential "didn't see that coming" downside as well...

Cheers!

Worked and completed my "Remote monitoring Setup's".

2 flow sensors - boguth from amazon $10 each - https://www.amazon.com/gp/product/B00QC6LI6Q/?tag=skimlinks_

Not a fan, foaming is bad.What do you think of the flow sensors Die Beerery? , I’m considering picking up a couple to keep up with keg amounts through BC.

Doesn't look bad at all from here?

fwiw, I use SwissFlow SF800 meters. You wouldn't even know they're in the lines...

Cheers!

I wonder if there would be less foaming through a flow control faucet?

I’ll look into the sf’s

I wonder if there would be less foaming through a flow control faucet?

I’ll look into the sf’s