I think you should do one where you walk us through the process!! Voiceover if you’re camera shy!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

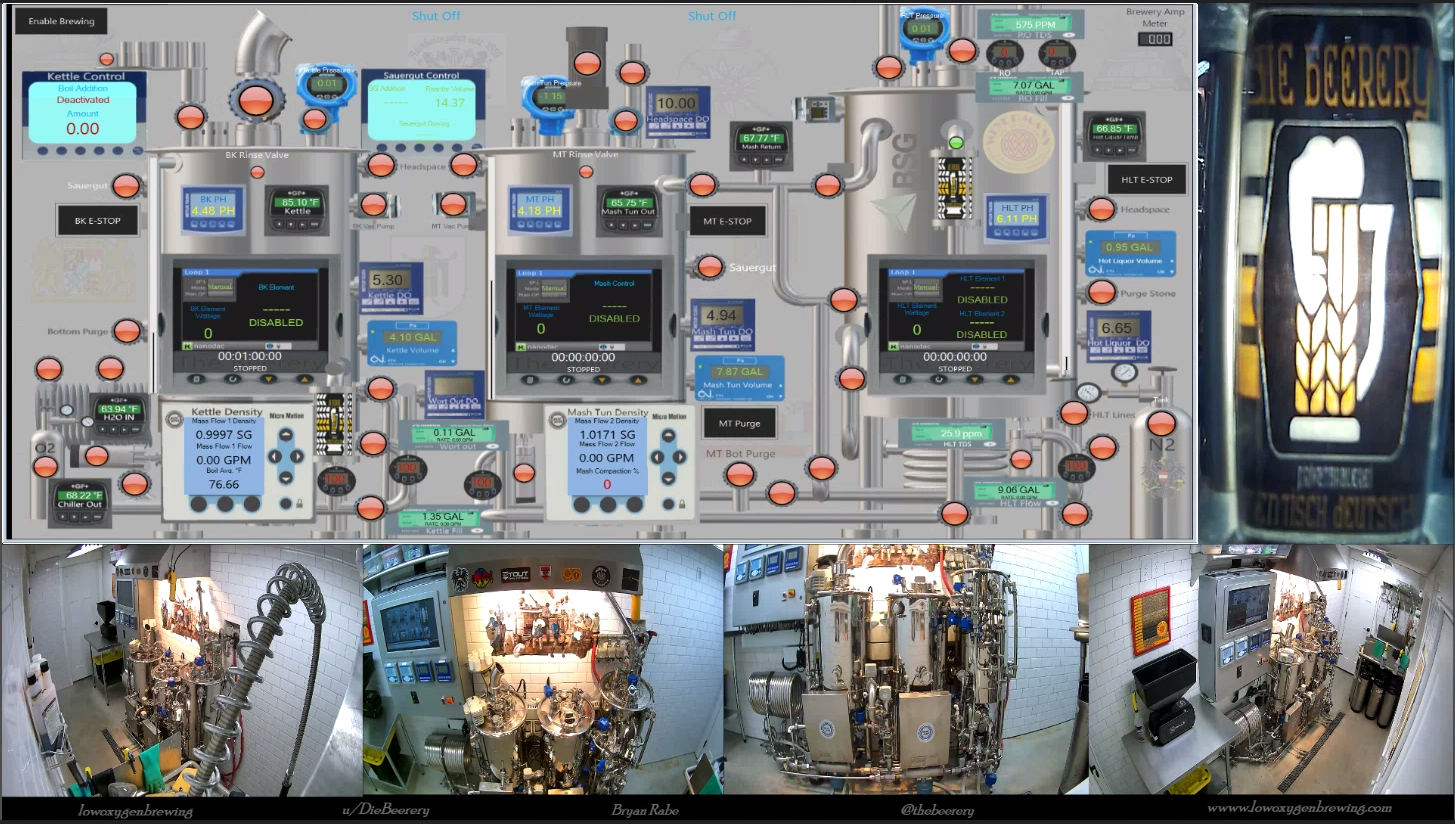

My mostly automated brucontrol setup

- Thread starter Die_Beerery

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I agree ^

John

John

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

That'd be a boring 6 hours of me talking!

That'd be a boring 6 hours of me talking!

Not boring at all, more like appreciating the work one has put into their project, and the process of how it all works would be the icing on the cake.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Quick and dirty ~12 minute overview

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

^^^^ Nicely done @Die_Beerery!! Your "step mash" is interesting in that it's 5 part as mentioned but something I didn't realize was the subtleties with such small incremental time/temp changes had such an effect on the different enzymes.

Thanks for sharing!!!

Thanks for sharing!!!

Last edited:

Awesome system! Thanks for posting that video!

VinceBrews

Well-Known Member

- Joined

- Oct 26, 2013

- Messages

- 59

- Reaction score

- 6

I'm curious about your setup for in-line oxygen. I've been trying to do this as well but I'm struggling to find a configuration that works well. I didn't want to have the tee with O2 diffusion stone on the line to the fermenter because I figured I'd have to take it apart to sanitize it. So instead, I put it upstream of the line out to the fermenter, in the loop from the BK to pump to CFC back to BK. This way, I could sanitize the stone by circulating boiling wort just like the CFC.

So, the stone barb goes to a motorized valve, and behind the valve is a gauge and O2 tank and regulator. The idea is, I leave the valve closed, set the regulator to whatever pressure I want (calibrated to give me the amount of O2 I want), and during transfer, I open the valve.

Problem is that when I circulate wort, the pressure in the line pushes wort up the line (through the stone and into my O2 line), even with the valve closed. When the valve is opened, the wort gets pushed back out, but I don't have a way to sanitize that line for the next time without taking everything apart (I'm trying hard to minimize that).

I tried putting a check valve in line, very close to the stone... but that leaked too (and would still leave the same issue between the tee and the check valve).

So, curious to know if you solved this problem... Maybe what I need to do is move the tee with the stone upstream of the valve so it never sees positive pressure (strictly, that should read no more positive pressure than the head from the wort in the BK to the tee). Or is there no way to avoid having to take this thing apart every time.

Very cool setup you have. Your videos have given ideas that I've implemented in my setup. You offered more detail info in your last video... I would watch it with interest! Thanks

So, the stone barb goes to a motorized valve, and behind the valve is a gauge and O2 tank and regulator. The idea is, I leave the valve closed, set the regulator to whatever pressure I want (calibrated to give me the amount of O2 I want), and during transfer, I open the valve.

Problem is that when I circulate wort, the pressure in the line pushes wort up the line (through the stone and into my O2 line), even with the valve closed. When the valve is opened, the wort gets pushed back out, but I don't have a way to sanitize that line for the next time without taking everything apart (I'm trying hard to minimize that).

I tried putting a check valve in line, very close to the stone... but that leaked too (and would still leave the same issue between the tee and the check valve).

So, curious to know if you solved this problem... Maybe what I need to do is move the tee with the stone upstream of the valve so it never sees positive pressure (strictly, that should read no more positive pressure than the head from the wort in the BK to the tee). Or is there no way to avoid having to take this thing apart every time.

Very cool setup you have. Your videos have given ideas that I've implemented in my setup. You offered more detail info in your last video... I would watch it with interest! Thanks

I also had a stone in-line the boil loop and had the same back-leakage. A check valve fixed it visually, but I’m confident some liquid is backing up into it as that air gets pressurized slightly. If that stone location is vertically lower that the level of the wort in the kettle, it will see hydrostatic pressure so liquid will creep into it.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Kolsch today and live streaming it.

Last edited:

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

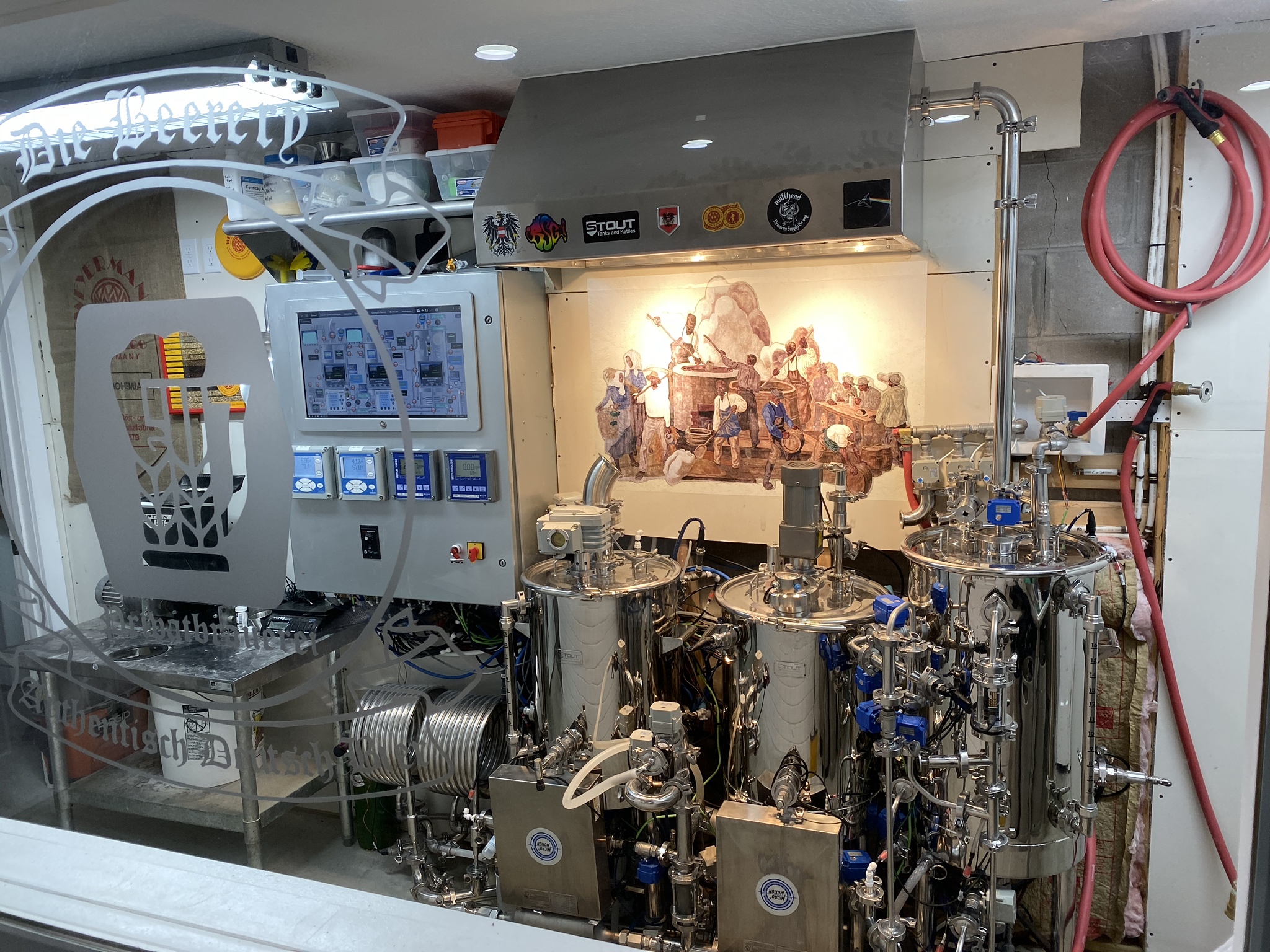

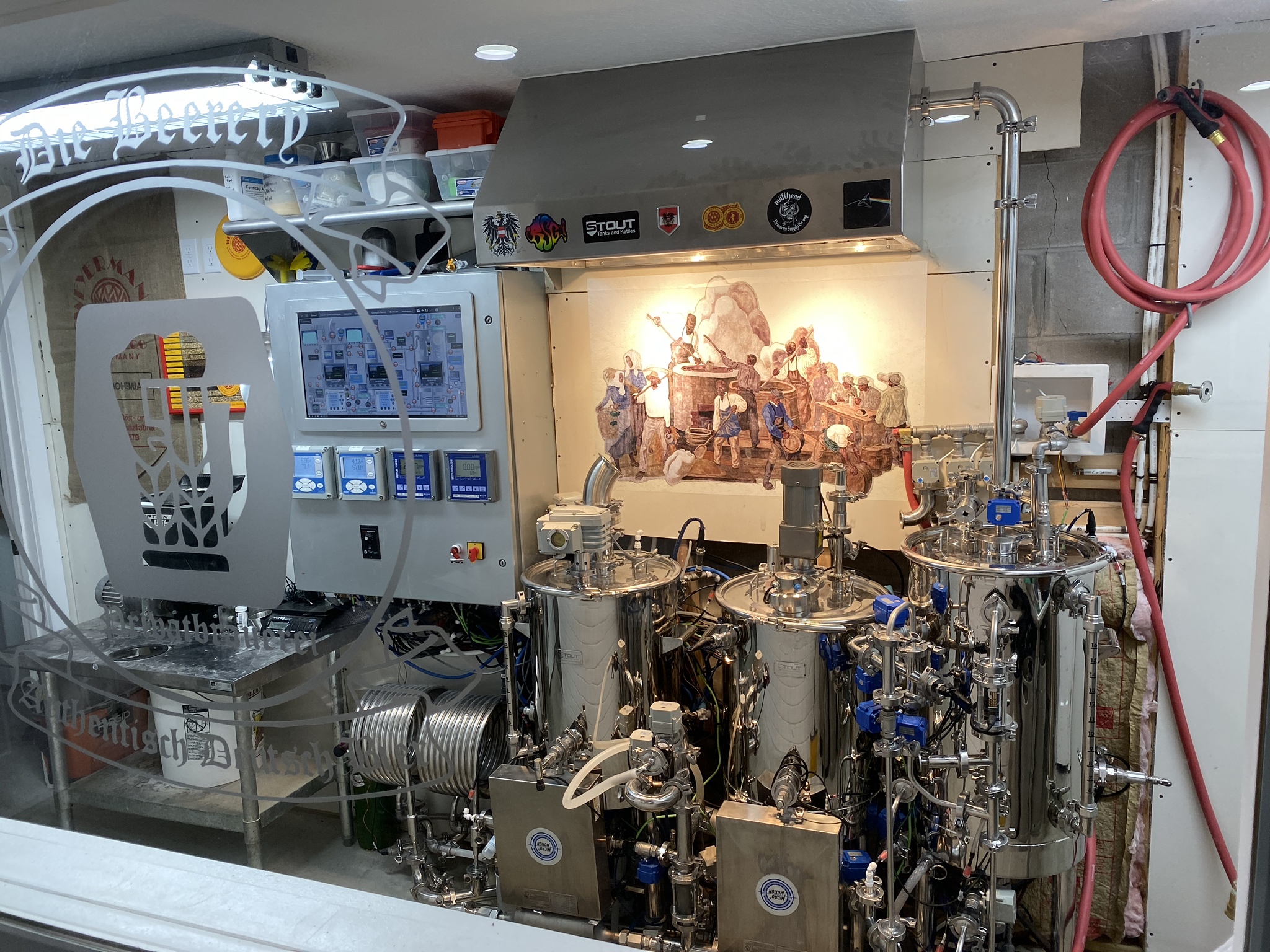

Been awhile-

Added a bunch of ****, refined a bunch of ****. Love bru-control, love the system, makes great beer. Adding a dirty system pic. That is all.

Added a bunch of ****, refined a bunch of ****. Love bru-control, love the system, makes great beer. Adding a dirty system pic. That is all.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

CIP work

CIP + Bottom Drain + Automation = very happy brewing!

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

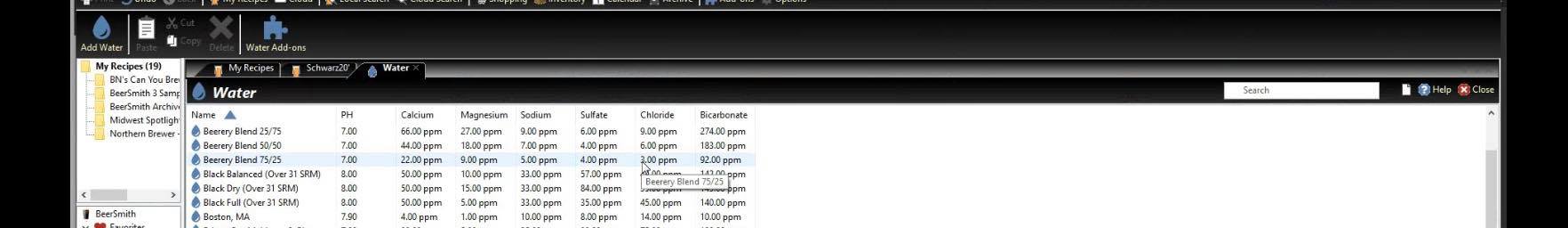

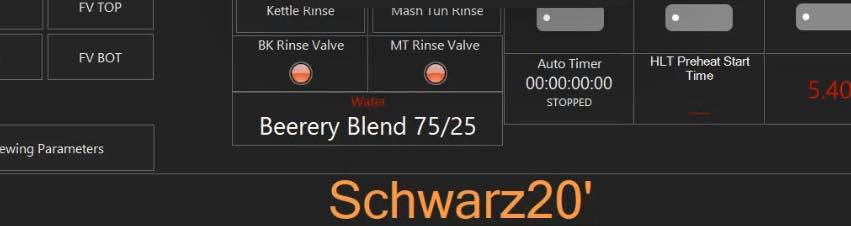

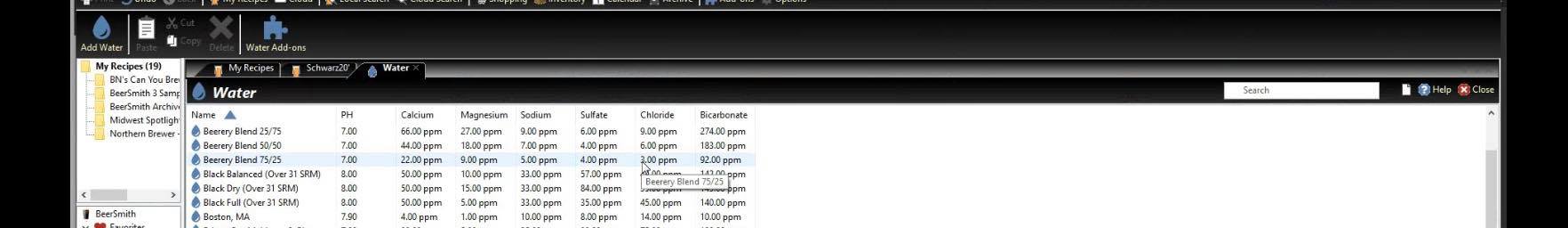

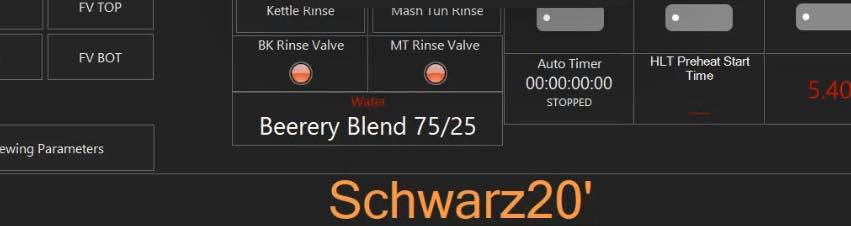

Project HLT water blender compete. Using some proportional valves and flow meters I can custom blend tap/ro water on the fly to achieve different water profiles without the use of water salts. How very Reinheitsgebot of me.

Colin Kaminski

Member

- Joined

- Aug 30, 2019

- Messages

- 6

- Reaction score

- 2

The other Reinheitsgebot thing I see is to use a conical tank to spin and steam heat water in order to settle alkalinity in the cone. The cone is bleed periodically. Nice work!

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

This and stuff. Will finish it soon.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Interface work...

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Got the Unitank all modeled for the bio-reactor. Added some oxygenation, stuff to the interface. Going to be using this for oxygenation instead of inline. Control can be much more precise when in a closed loop and not pass thru. Added a PWM DC pump for the ability to "stir" the bio reactor, for hops, or whatnot.

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Final test of Load sensors, milling script and grain delivery. Brewday hopefully this weekend.

View attachment 668494

View attachment 668494

Love it!

Where's the silo and auger transfer system?

I mean, I hope you're not still manually loading the mill like us peons, fer cripe's sake!

Cheers!

I mean, I hope you're not still manually loading the mill like us peons, fer cripe's sake!

Cheers!

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Where's the silo and auger transfer system?

I mean, I hope you're not still manually loading the mill like us peons, fer cripe's sake!

Cheers!

Augers are so Stone Age. Load cells and Venturi’s are where it’s at. At least that’s how I going to do it.

[emoji16]

ClaudiusB

Well-Known Member

Die_Beerery

Well-Known Member

- Joined

- Aug 21, 2017

- Messages

- 842

- Reaction score

- 643

Been working and tweaking this for a while, but this is the first official 2020 Live stream. Always up for ways to make this better so let me know. I will have the chat boxes open while I brew.

Links here

http://www.lowoxygenbrewing.com/youtube/

Links here

http://www.lowoxygenbrewing.com/youtube/

bradleym734

Member

- Joined

- Mar 10, 2020

- Messages

- 11

- Reaction score

- 1

What are the model numbers of the micro motion flow meters and transmitters?

aeviaanah

Well-Known Member

- Joined

- Jul 1, 2012

- Messages

- 1,686

- Reaction score

- 217

Please tell me moreLoading like peons stopped many rears ago. All done with air.

View attachment 668869 View attachment 668870 View attachment 668871 View attachment 668873

Similar threads

- Replies

- 5

- Views

- 1K

- Replies

- 44

- Views

- 2K