ClaudiusB

Well-Known Member

How is your mill performing after all this months ?I have a brew slated for next week, so I can check it under load then.

How is your mill performing after all this months ?I have a brew slated for next week, so I can check it under load then.

Just saw this. My mill is still working like when I built it. Milled about 20lbs a few weeks ago, but no rye yet!How is your mill performing after all this months ?

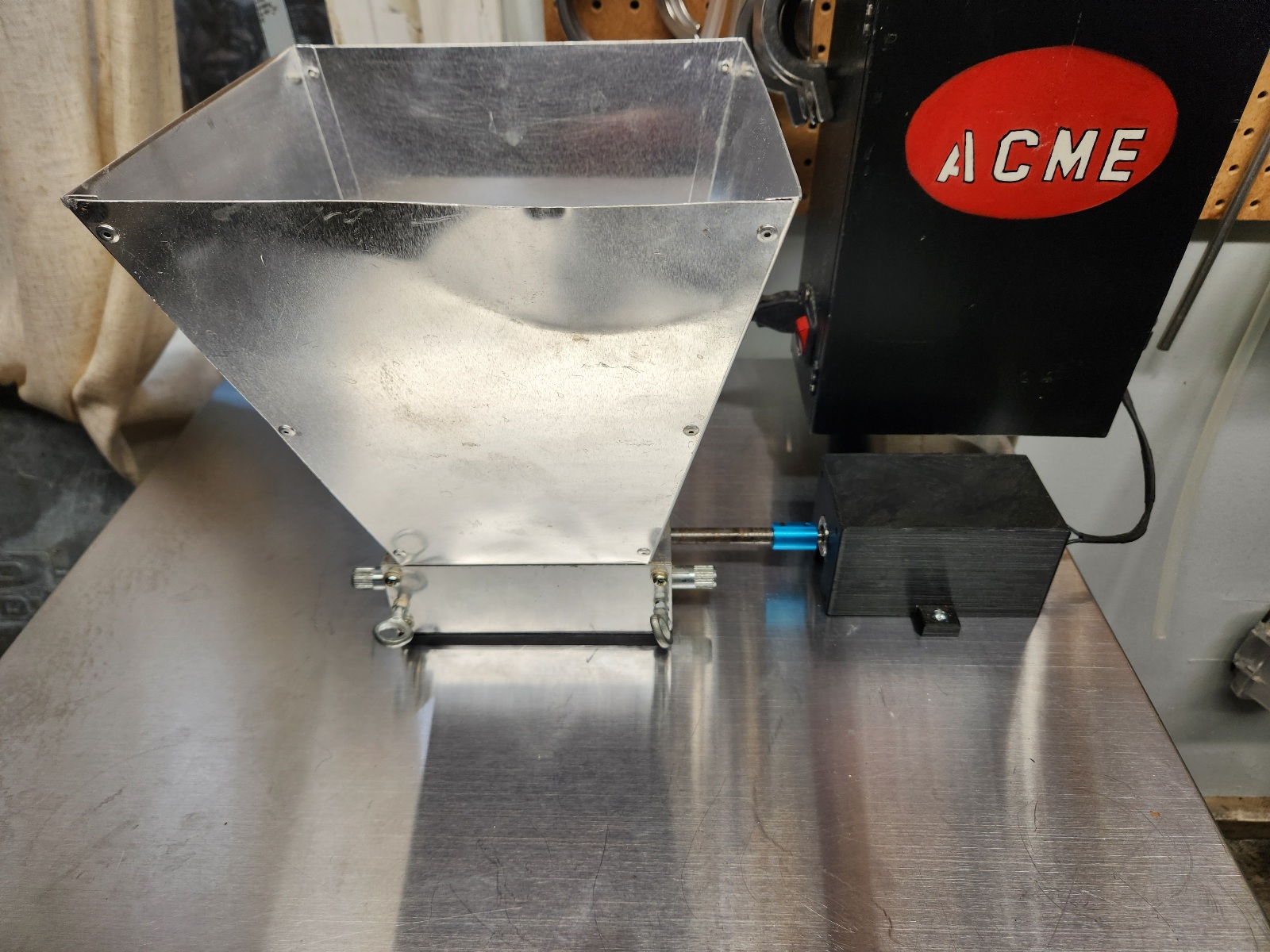

I've been using a Harbor Freight Low Speed Drill (550 rpm max), mounted to the mill's baseboard. It chews through a hopper full of malt within a couple minutes. I'm milling at around 150 rpm under load with a Monster Mill MM2 (1.5" rollers).Dang! Need a tougher motor.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I have one as well but mine is variable I think it’s similar to this, as far as my mill I replaced the bearings several years ago, all is well sinceI've been using a Harbor Freight Low Speed Drill (550 rpm max), mounted to the mill's baseboard. It chews through a hopper full of malt within a couple minutes. I'm milling at around 150 rpm under load with a Monster Mill MM2 (1.5" rollers).

HF now has a newer version of that low speed drill with similar specs but at a max speed of 600 rpm for around $60 or less (w/ coupons).

Yeah, mine (the older, gray model) has variable speed too, with an adjustable limiter wheel.I have one as well but mine is variable I think it’s similar to this

Thanks! Still works just fine. I had a little 2-way toggle switch I got from somewhere (for forward and reverse) and made a little aluminum plate for its mount. So I guess manually wired it. No remote (no need for me). Used a cord for plugging it into a wall socket when I'm using it. Has a little black rectangular box that I assume is a capacitor that it needs.. came with the motor. I bet a lot of those motors go to the dump or e-waste. Nothing wrong with 'em if you have a use. Good torque.That’s actually a pretty clever workaround — using a treadmill ramp motor is next-level DIY!

Sometimes the "not-so-elegant" fixes last longer than factory setups. Curious — did you rig it to a switch or remote, or just wired it manually?

I've noticed a lot of dust collects under my table when milling - I try to brush it into the bucket after milling but it is a bit of a mess and hassle. I needs me a chute.. keep thinking up excuses to buy a 3-d printer. Suppose I could fashion one out of tin or wood.Had to do some long-needed updating to the table. With no chute on the table it was becoming quite a mess.

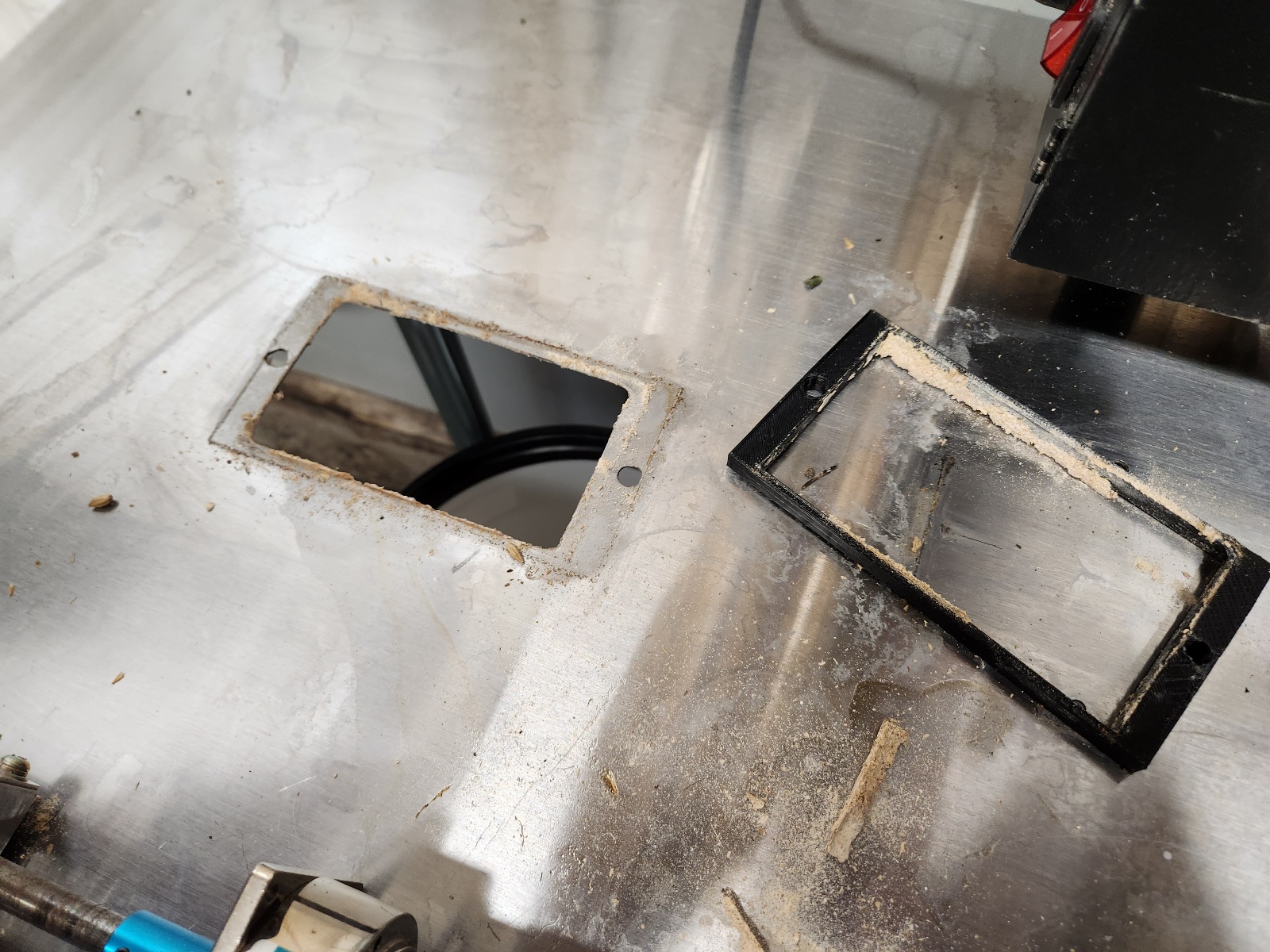

So I redesigned the spacer to include a short chute. Thinking about making a detachable chute so I can clean it easier. Also printed out a gasket out of TPU to try to keep the dust out of the spacer - mill interface.

Ever tried malt conditioning?I really need to do that to my mill. Right now there's barely a 4" open drop but even that can result in thick malt dust all around the inside of the mill cabinet when the humidity is low. Gotta get 'er done

View attachment 835352

Cheers!

Nope. Now I remember reading somewhere about doing that after forgetting about it.. I'll give it a try.. seems easy enough. Thanks.Ever tried malt conditioning?

I use 2% sprayed, and left for 15 minutes. Then a much better crush, and hardly any dust.

Ever tried malt conditioning?

You can't prevent dust from being formed and most will collect underneath the mill. A (deep) chute should help contain most of it.I've noticed a lot of dust collects under my table when milling - I try to brush it into the bucket after milling but it is a bit of a mess and hassle. I needs me a chute..

I cut open a pillowcase and stapled it to the bottom plate of my mill to make a cloth chute. It keeps the grain and dust going into the old malt sack I use to collect the milled malt. Since I make 10 gallon batches, 20-30 pounds of malt is common.I really need to do that to my mill. Right now there's barely a 4" open drop but even that can result in thick malt dust all around the inside of the mill cabinet when the humidity is low. Gotta get 'er done

View attachment 835352

Cheers!

This also works well for me.cloth chute.

Requested... please explainMy grain mill is outside, and the dust is not a big problem; an opening in the front vents a lot of the dust outside.

My simple mill has been a hard worker for over thirty years.

The mill has several sensors to ensure a steady flow of grain delivery to the mash tun when requested by the brewery, located approximately fifty feet away.

What would you like to know?Requested... please explain

This partThe mill has several sensors to ensure a steady flow of grain delivery to the mash tun when requested by the brewery

Here are the functions of the mill sensors. I won't go into the details of the grain flow under different operational modes.This part

Ah shucks.. thanks!That’s some solid DIY ingenuity!Using a garage door opener motor was a clever starting point—too bad about that plastic gear giving out. You’re right, a stronger-grade gear might’ve made it last much longer. And props for thinking outside the box with the treadmill motor—that’s a great source for high-torque, reversible movement. Sometimes, the most unconventional solutions are the most effective. Curious, did you have to rig a custom mount or controller for the treadmill motor, or did it fit in pretty cleanly? Residential Garage Door Repair Santa Clarita

fwiw, the gears themselves are fine - but the gear on the actual motor shaft is press-fit. Apparently, high load weakened that joint. I lack the ability to weld it. Oh well.it failed -- apparently a broken gear tooth, though hard to be sure what happened. Motor spins but output shaft only works with low or no load at this point

Wonder what load those are rated for. Still going strong on mine. Still no rye yet!fwiw, the gears themselves are fine - but the gear on the actual motor shaft is press-fit. Apparently, high load weakened that joint. I lack the ability to weld it. Oh well.

YMMV, but I recommend you crush any tough grains another way.Still no rye yet!

Torque of what seems to be the same unit as mine (24V, 50rpm) iis rated at "16.04 kgf.cm" on aliexpress, whatever that means. I haven't seen an exact match for yours, but the higher rpm corresponds linearly to considerably lower torque on the charts I've seen, perhaps only about 6 kgf.cm. I'm not sure this tells us when the unit will break; probably, when it will stop turning if it doesn't break.what load those are rated for