shoengine

Whale Noun Member

I'm checking on this...Your mill setup is looking amazing!

Any word on clamp make/model and sources for clamp & motor?

I'm checking on this...Your mill setup is looking amazing!

Any word on clamp make/model and sources for clamp & motor?

Looks good @shoengine - don't worry about testing it starting with a full hopping for my sake (don't want it getting busted just for my curiosity).I can't speak to the torque requirements. I did mention to my friend that finding a motor that could run slow and put up with the milling was very difficult. I've milled with it twice so far and both times it worked well, with no struggling. I usually start my mill before dumping the grain in, but next time I'll try starting it after filling the hopper.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

One naked, one with a slapped together enclosure.Do you have a video of the whine?

How is your mill performing after all this months ?I have a brew slated for next week, so I can check it under load then.

Just saw this. My mill is still working like when I built it. Milled about 20lbs a few weeks ago, but no rye yet!How is your mill performing after all this months ?

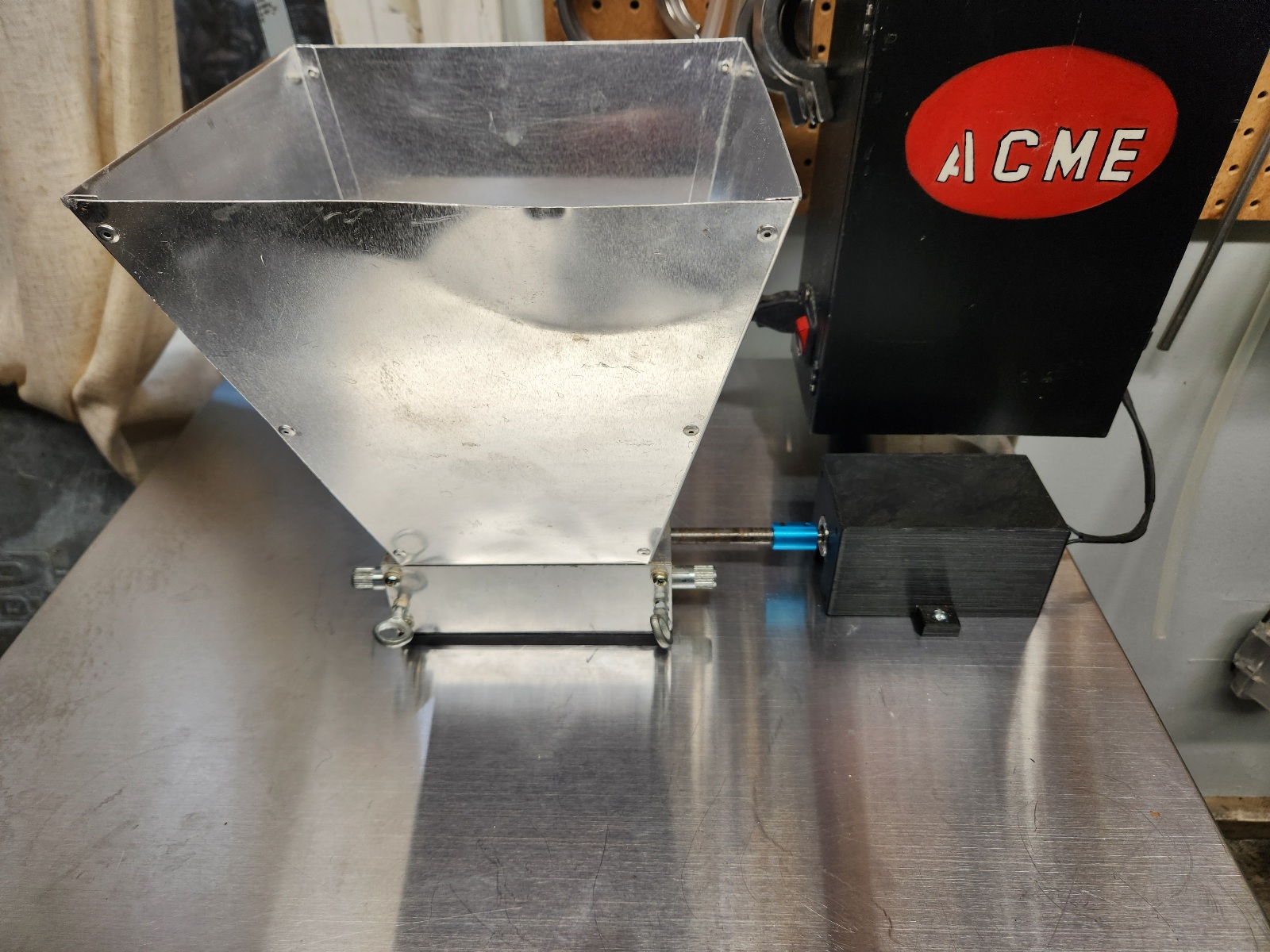

I've been using a Harbor Freight Low Speed Drill (550 rpm max), mounted to the mill's baseboard. It chews through a hopper full of malt within a couple minutes. I'm milling at around 150 rpm under load with a Monster Mill MM2 (1.5" rollers).Dang! Need a tougher motor.

I have one as well but mine is variable I think it’s similar to this, as far as my mill I replaced the bearings several years ago, all is well sinceI've been using a Harbor Freight Low Speed Drill (550 rpm max), mounted to the mill's baseboard. It chews through a hopper full of malt within a couple minutes. I'm milling at around 150 rpm under load with a Monster Mill MM2 (1.5" rollers).

HF now has a newer version of that low speed drill with similar specs but at a max speed of 600 rpm for around $60 or less (w/ coupons).

Yeah, mine (the older, gray model) has variable speed too, with an adjustable limiter wheel.I have one as well but mine is variable I think it’s similar to this

Thanks! Still works just fine. I had a little 2-way toggle switch I got from somewhere (for forward and reverse) and made a little aluminum plate for its mount. So I guess manually wired it. No remote (no need for me). Used a cord for plugging it into a wall socket when I'm using it. Has a little black rectangular box that I assume is a capacitor that it needs.. came with the motor. I bet a lot of those motors go to the dump or e-waste. Nothing wrong with 'em if you have a use. Good torque.That’s actually a pretty clever workaround — using a treadmill ramp motor is next-level DIY!

Sometimes the "not-so-elegant" fixes last longer than factory setups. Curious — did you rig it to a switch or remote, or just wired it manually?

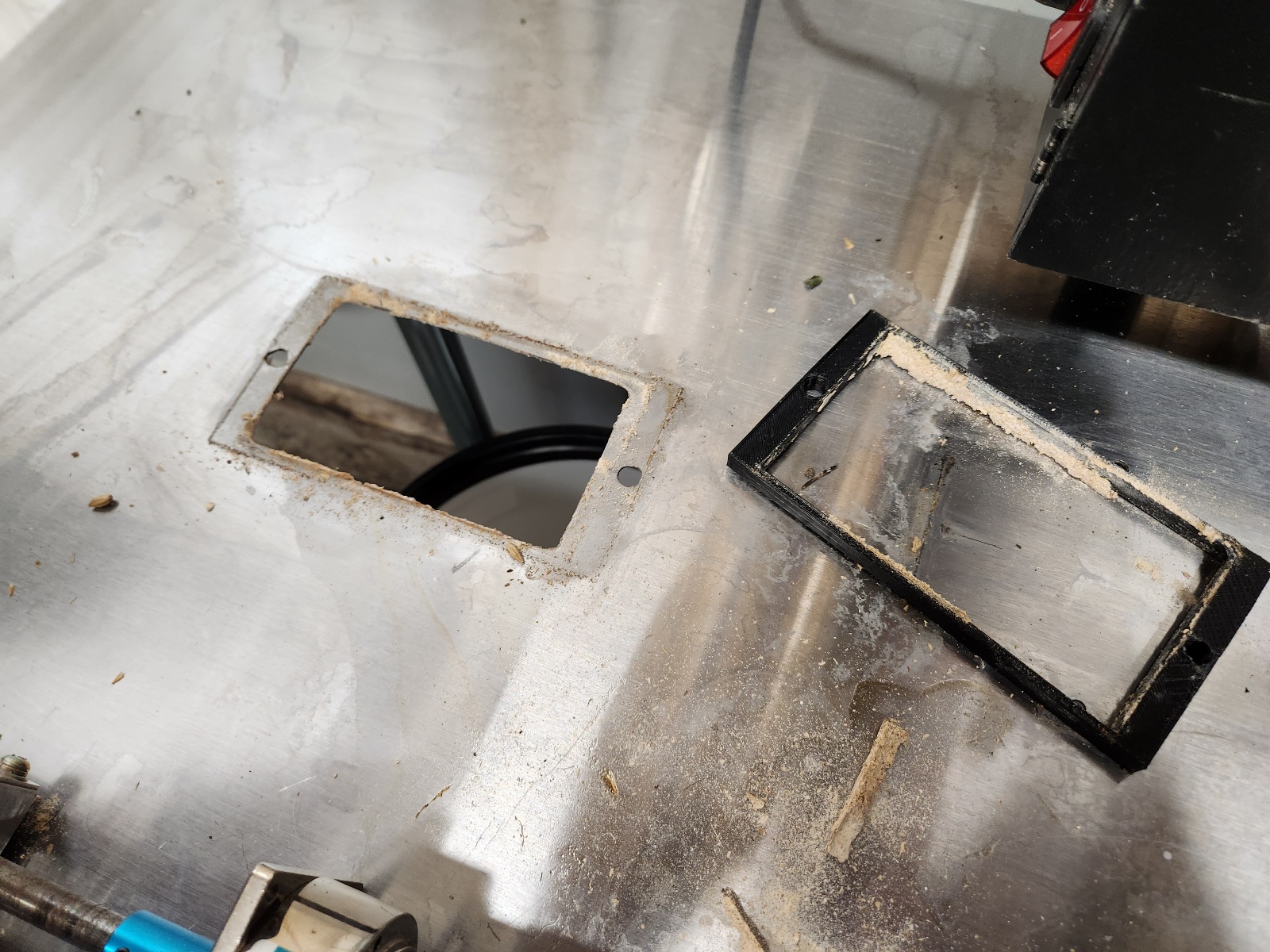

I've noticed a lot of dust collects under my table when milling - I try to brush it into the bucket after milling but it is a bit of a mess and hassle. I needs me a chute.. keep thinking up excuses to buy a 3-d printer. Suppose I could fashion one out of tin or wood.Had to do some long-needed updating to the table. With no chute on the table it was becoming quite a mess.

So I redesigned the spacer to include a short chute. Thinking about making a detachable chute so I can clean it easier. Also printed out a gasket out of TPU to try to keep the dust out of the spacer - mill interface.

Ever tried malt conditioning?I really need to do that to my mill. Right now there's barely a 4" open drop but even that can result in thick malt dust all around the inside of the mill cabinet when the humidity is low. Gotta get 'er done

View attachment 835352

Cheers!

Nope. Now I remember reading somewhere about doing that after forgetting about it.. I'll give it a try.. seems easy enough. Thanks.Ever tried malt conditioning?

I use 2% sprayed, and left for 15 minutes. Then a much better crush, and hardly any dust.

Ever tried malt conditioning?

You can't prevent dust from being formed and most will collect underneath the mill. A (deep) chute should help contain most of it.I've noticed a lot of dust collects under my table when milling - I try to brush it into the bucket after milling but it is a bit of a mess and hassle. I needs me a chute..

I cut open a pillowcase and stapled it to the bottom plate of my mill to make a cloth chute. It keeps the grain and dust going into the old malt sack I use to collect the milled malt. Since I make 10 gallon batches, 20-30 pounds of malt is common.I really need to do that to my mill. Right now there's barely a 4" open drop but even that can result in thick malt dust all around the inside of the mill cabinet when the humidity is low. Gotta get 'er done

View attachment 835352

Cheers!

This also works well for me.cloth chute.