After using one of these for 3-4 years now, I do not see any reason to stop. Outside of the O2 benefits, It helps to keep temps stable and returning the recirc flow under the water instead of sprinkling on top of the liquid just makes more logical sense to me. Why purposefully aerate if one does not have to? Just dogmatic imho.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mash Caps... Let me see what you got!

- Thread starter DonT

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Feb 16, 2012

- Messages

- 4,647

- Reaction score

- 7,073

- Location

- At home, in the brewery in Maryland.

That's my approach to LoDO (please, don't judge me) brewing. Not a chest-beating acolyte. It just makes sense to me.After using one of these for 3-4 years now, I do not see any reason to stop. Outside of the O2 benefits, It helps to keep temps stable and returning the recirc flow under the water instead of sprinkling on top of the liquid just makes more logical sense to me. Why purposefully aerate if one does not have to? Just dogmatic imho.

beersk

Well-Known Member

- Joined

- Mar 22, 2013

- Messages

- 1,915

- Reaction score

- 1,208

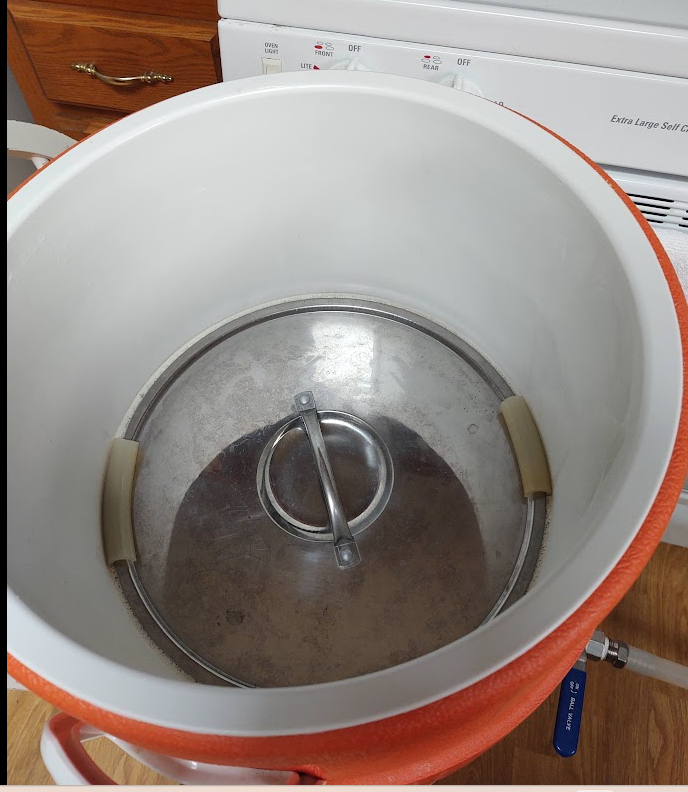

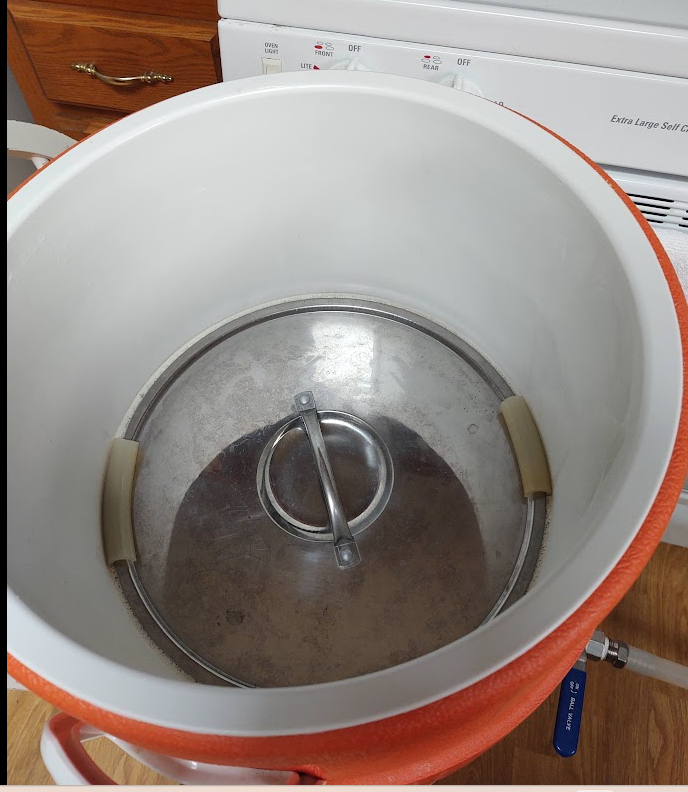

I use the lid from my original 5 gallon stock pot when I started brewing. It fits perfectly in a 10 gallon Igloo cooler. @Red over White Why even bother with yours? I looks like it covers only about 50-60% over your mash. Cover 100% or bust, I say.

Red over White

Well-Known Member

I have 3 mashtuns, that cap pulls double duty for the AIO & 8 gal HLT, but it is stored in my direct fired 16 gal mashtun where I took the picture. I have a 3v gas system and an indoor 3v electric system. TBH, I can't wait to brew outside again on propane this spring when I can set everything up the night before.I use the lid from my original 5 gallon stock pot when I started brewing. It fits perfectly in a 10 gallon Igloo cooler. @Red over White Why even bother with yours? I looks like it covers only about 50-60% over your mash. Cover 100% or bust, I say.

View attachment 840623

- Joined

- Feb 16, 2012

- Messages

- 4,647

- Reaction score

- 7,073

- Location

- At home, in the brewery in Maryland.

You’re singin’ my song. I’m past ready for Spring to be here yesterday. I’ve still got two partial kegs in the kegerator and one more untapped in the beer fridge. BUT I WANT TO BREW!!!I have 3 mashtuns, that cap pulls double duty for the AIO & 8 gal HLT, but it is stored in my direct fired 16 gal mashtun where I took the picture. I have a 3v gas system and an indoor 3v electric system. TBH, I can't wait to brew outside again on propane this spring when I can set everything up the night before.

Sick and tired of lookin’ out the window and seeing cold, dark skies. SWMBO’d says “No” to indoor brewing, so I’m S.O.L. until Winter breaks. Got 70~80# of grain in Vittle Vaults, a freezer full of hops, and a metric crap ton of yeast that’s ready to go. And at least two dozen recipes that I want to brew (but prolly never will) with the list growing daily ‘cause I waste my days hangin’ with my homies here on HBT rather than actually making beer!

Only the act of brewing will break the fever.

Red over White

Well-Known Member

You’re singin’ my song. I’m past ready for Spring to be here yesterday. I’ve still got two partial kegs in the kegerator and one more untapped in the beer fridge. BUT I WANT TO BREW!!!

Sick and tired of lookin’ out the window and seeing cold, dark skies. SWMBO’d says “No” to indoor brewing, so I’m S.O.L. until Winter breaks. Got 70~80# of grain in Vittle Vaults, a freezer full of hops, and a metric crap ton of yeast that’s ready to go. And at least two dozen recipes that I want to brew (but prolly never will) with the list growing daily ‘cause I waste my days hangin’ with my homies here on HBT rather than actually making beer!

Only the act of brewing will break the fever.

Yeah, I love the ground water temps in the winter, but I'd rather be brewing outside while grilling or smoking something. This weekend I will do another fest beer and put a maibock on that yeast cake asap. I've got 4 more weeks until I can be outside here in NC without lines nearly freezing overnight.

I feel ya, big winter beers don't get depleted as quickly and the brew days get further apart. I love setting aside a whole day to JUST brew and eat to much. Hopefully, that big rodent in PA sez you don't have 6 more weeks of winter!

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$159.50 ($26.58 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

Amazon.com

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

- Joined

- Feb 16, 2012

- Messages

- 4,647

- Reaction score

- 7,073

- Location

- At home, in the brewery in Maryland.

This winter hasn’t been that bad this year, but I’ve had enough. We’ll be heading down to Florida in a few weeks to thaw out with our grandkids there. By the time we get back it’ll be tax time, then hopefully the weather will warm enough to get brewing, regardless of what that overgrown rat in Punxsutawney does.Yeah, I love the ground water temps in the winter, but I'd rather be brewing outside while grilling or smoking something. This weekend I will do another fest beer and put a maibock on that yeast cake asap. I've got 4 more weeks until I can be outside here in NC without lines nearly freezing overnight.

I feel ya, big winter beers don't get depleted as quickly and the brew days get further apart. I love setting aside a whole day to JUST brew and eat to much. Hopefully, that big rodent in PA sez you don't have 6 more weeks of winter!

- Joined

- Feb 16, 2012

- Messages

- 4,647

- Reaction score

- 7,073

- Location

- At home, in the brewery in Maryland.

Oh, I hear that. I spent three years in the late 70s south of San Antonio instructing Student Naval Aviators in the fine art of not killing one’s self in an airplane. I was mostly successful. One summer (1980 to be exact) it didn’t rain for over three months.Suck it up and get out there!Just kidding. I prefer a warm brew day as well but the show must go on. In Texas, I only get a few times a year when the chiller really works well.

There was a stretch of 90 days when the temperature exceeded 90F, including 30 consecutive days when it was in excess of 100F. Often the overnight low temperature was still above 90F. Even with an air conditioned cockpit, it got mighty hot under a plexiglass bubble canopy.

It took Hurricane Allen to finally break the fever as well as the drought. Of course my wife was in a hospital in Corpus Christi 60 miles away with our newborn daughter when the storm came ashore at South Padre Island.

Certainly not weather conducive to brewing beer, or barbeque either. Sure do miss the flavor of mesquite done right, however.

beersk

Well-Known Member

- Joined

- Mar 22, 2013

- Messages

- 1,915

- Reaction score

- 1,208

I often miss my brewing outside days. I lived in a place with a garage for a while and I loved it, even in the winter. Just had to mash inside and carry the kettle outside/back inside for chilling. I remember brewing one day when it was 6F. That was fun. Could barely see the boil. That was a hoppy red I brewed way back in January of 2010. Loved it.

But now I brew inside and it's so much better. No bugs, no wind, limitless gas supply, it's all right there. I don't have to worry about anyone not liking the smell thankfully. I do often wish I had a garage so I could brew outside though...

But now I brew inside and it's so much better. No bugs, no wind, limitless gas supply, it's all right there. I don't have to worry about anyone not liking the smell thankfully. I do often wish I had a garage so I could brew outside though...

I have been brewing in the garage for 20+ years. It is fine but I would love a dedicated indoor space. Maybe some day but it seems indulgent just for a hobby.

You’re singin’ my song. I’m past ready for Spring to be here yesterday. I’ve still got two partial kegs in the kegerator and one more untapped in the beer fridge. BUT I WANT TO BREW!!!

Sick and tired of lookin’ out the window and seeing cold, dark skies. SWMBO’d says “No” to indoor brewing, so I’m S.O.L. until Winter breaks. Got 70~80# of grain in Vittle Vaults, a freezer full of hops, and a metric crap ton of yeast that’s ready to go. And at least two dozen recipes that I want to brew (but prolly never will) with the list growing daily ‘cause I waste my days hangin’ with my homies here on HBT rather than actually making beer!

Only the act of brewing will break the fever.

Red over White

Well-Known Member

Setting up for Saturday mornings 10 gal batch of festbier. This is my mash cap in the 17 gal brewzilla. It's a SS pizza pan with the exact hardware my other cap has underneath. It has a small gap not visible because of its shape, but it’s very effective and moves up and down freely.

Is there something under that cap to disperse the return so it isn't drilling straight down into the mash bed?

Cheers!

Cheers!

Red over White

Well-Known Member

Yes, this is the underside. Fugly, but effective.Is there something under that cap to disperse the return so it isn't drilling straight down into the mash bed?

Cheers!

The SS wire and ring on my mash caps were robbed from SS colanders to deflect the flow off the bottom of the cap and to not to cause disturbance to the surface or the grain bed.

Boring ass explanation not asked for:

This was proved out initially with a stale mash after runoff. I just kept playing with it until I seen the desirable results. The return shouldn't create any turbulence around the cap, any interaction is inducing oxygen. If it's completely still with no undulations the only issue will be the CO² generated from dough-in and the ingress that is inherent with bubble xfer is that those CO² bubbles will cause on the surface. Bubbles on the surface of the mash create a much bigger surface area and thus a bigger area for oxygen ingress. That much reduced surface area can be easily tamped down with preemptive antioxidants though. If that sounds goofy, I can refine it hopefully better if need be.

Anyone design a mash cap for a keggle? (Yes I still use a keggle.)

The problem is the top hole is 10-inches, and the keg is15-inches. My false bottom is hinged and folds. Would a silicone baking sheet float? They're pretty cheap on Amazon and I could cut one down, but not sure it would float. I use a RIMS, so wort is recirculating with just a tube lying on top of the mash. The cap would have to float on top of that. Thoughts?

The problem is the top hole is 10-inches, and the keg is15-inches. My false bottom is hinged and folds. Would a silicone baking sheet float? They're pretty cheap on Amazon and I could cut one down, but not sure it would float. I use a RIMS, so wort is recirculating with just a tube lying on top of the mash. The cap would have to float on top of that. Thoughts?

@Schlenkerla mash ball approach seems like it would work. He floated a bunch of small balls on the mash.

I think the silicon baking sheet might work if it is think enough to maintain buoyancy as one entity and actually stay on top of the liquid. You could possibly make a hole in the center to tun your recirc tubing through to let the silicon free float around it.Anyone design a mash cap for a keggle? (Yes I still use a keggle.)

The problem is the top hole is 10-inches, and the keg is15-inches. My false bottom is hinged and folds. Would a silicone baking sheet float? They're pretty cheap on Amazon and I could cut one down, but not sure it would float. I use a RIMS, so wort is recirculating with just a tube lying on top of the mash. The cap would have to float on top of that. Thoughts?

Do you or anyone have a link for where to get this material? ThanksNeedless to say, I fretted over that too. Its a foamed polypropylene material and the material is food safe.

duelerx

Well-Known Member

- Joined

- Nov 5, 2015

- Messages

- 258

- Reaction score

- 93

I liked this idea from the other lodo forum, it is quite a challenge finding a light kettle cap that floats and fits nicely in my kettle. I saw these sous-vide balls available in Amazon that are cheap, maybe i pull the trigger to use them on my mash and post-boil.I use these food grade floating Polypropylene balls that someone recommended in another thread. They are pharmaceutical / food grade up to 230F

Been working really well as both a mash cap & lauter / whirlpool cap. DO numbers stay below 1ppm during mash, lauter, and whirlpool. No DMS & the hop aroma really gets locked in during the hopstands. They still allow for some evaporation, but not much

They add about 20 min of extra cleaning time, but I've gotten the hang of it. Its not as bad as it looks to deal with to scoop them out since they float to the top with water.

https://www.homebrewtalk.com/threads/diy-float-ball-for-sparge-water.524794/

The nice thing is they don't get in the way of any media I throw into the kettle like chillers, whirlpool arms, loc line etc. View attachment 833028View attachment 833029

I liked this idea from the other lodo forum, it is quite a challenge finding a light kettle cap that floats and fits nicely in my kettle. I saw these sous-vide balls available in Amazon that are cheap, maybe i pull the trigger to use them on my mash and post-boil.

If you want to get the ones I use you can contact this vendor and ask for 1000 of the 20mm polypropylene balls (FDA grade)

[email protected]

https://eccllc.us/

The amazon ones look comparable, but I prefer ordering from the manufacturer as I don't always trust amazon. Especially to ensure these are food grade.

IMPRESA [500 Count] Sous Vide Balls for Anova Sous Vide Container, for Inkbird Sous Vide Container & Other Models - Sous Vide Container Balls to Reduce Heat Loss & Evaporation - Accessories

https://a.co/d/8erQFTK

The only place I’ve seen anything like this is in the variable capacity tanks they use for wine making. Those all have a lid that can be moved up or down with the volume in the tank. I’m not sure if anything can be gained by looking at those - I’m figuring they are used for fermentation so probably not designed to be used with any heat. Those kind of tanks are expensive. I don’t know anything about those lids, how they work, or if anything sold for that purpose might be adaptable for what you’re after? But it seems like they use some kind of pump to pump up something to hold the lid where they want it.

Last edited:

I finally found a floating pan that fits my 15G Blichmann kettle like it was designed for it. With the BIAB bag in place, there is JUST enough clearance to slide the pan in and it floats perfectly on the surface of the mash.

I drilled and press fit in a piece of 1/2" OD SS tubing with a TC cap welded to the end on the underside of the cap as a recirc diffusor.

I could see dropping in a disc of closed cell foam on the top for even better insulation and then I'd probably not use the kettle lid at all. Without the extra insulation, the air gap seems like a good idea. It's just a pain to connect the hoses with the lid as an intermediate barrier.

The main frustration that will absolutely need some workaround if I keep using a cap, is not being able to determine my recirculation rate. I have to lift the cap and it splashes like crazy. Oh, the other problem is that it's really hard to pull samples for pH and gravity. I used to just lift the lid and steal samples from the end of the loc-line. This can probably be solved by adding another tee and a sample valve but it's a lot of hardware to throw at a simple problem.

I drilled and press fit in a piece of 1/2" OD SS tubing with a TC cap welded to the end on the underside of the cap as a recirc diffusor.

I could see dropping in a disc of closed cell foam on the top for even better insulation and then I'd probably not use the kettle lid at all. Without the extra insulation, the air gap seems like a good idea. It's just a pain to connect the hoses with the lid as an intermediate barrier.

The main frustration that will absolutely need some workaround if I keep using a cap, is not being able to determine my recirculation rate. I have to lift the cap and it splashes like crazy. Oh, the other problem is that it's really hard to pull samples for pH and gravity. I used to just lift the lid and steal samples from the end of the loc-line. This can probably be solved by adding another tee and a sample valve but it's a lot of hardware to throw at a simple problem.

The main frustration that will absolutely need some workaround if I keep using a cap, is not being able to determine my recirculation rate.

<cough> You have three of these still in stock

I'll be using mine soon.

I periodically continue my search for a pan that fits my 20 gallon G1 kettles. A 17-1/2" diameter SS pan or lid or whatever that'd float would be perfect but I've yet to find one. My notion of a diffuser is pretty much embodied by your example. Nicely done!

Cheers!

Looks good Bobby. I found some long plastic pipettes that I take gravity samples with. So I can check by just inserting it around the edge of the mash cap. pH has a little more liquid involved so I have a little SS scoop that I put under the recirc flow for a short bit. Pain to lift the cap but pH is only once during the mash and often is not needed for repeat recipes.I finally found a floating pan that fits my 15G Blichmann kettle like it was designed for it. With the BIAB bag in place, there is JUST enough clearance to slide the pan in and it floats perfectly on the surface of the mash.

View attachment 864794

I drilled and press fit in a piece of 1/2" OD SS tubing with a TC cap welded to the end on the underside of the cap as a recirc diffusor.

View attachment 864795

I could see dropping in a disc of closed cell foam on the top for even better insulation and then I'd probably not use the kettle lid at all. Without the extra insulation, the air gap seems like a good idea. It's just a pain to connect the hoses with the lid as an intermediate barrier.

The main frustration that will absolutely need some workaround if I keep using a cap, is not being able to determine my recirculation rate. I have to lift the cap and it splashes like crazy. Oh, the other problem is that it's really hard to pull samples for pH and gravity. I used to just lift the lid and steal samples from the end of the loc-line. This can probably be solved by adding another tee and a sample valve but it's a lot of hardware to throw at a simple problem.

I'm still searching for something that might work, too. I still use a keggle as my MT, so I need something to fold like the false bottom I have. Anyone try using those silicone baking mats and cutting it down? Just don't think they would float/stay on top of the mash when recirculating.

- Joined

- Feb 16, 2012

- Messages

- 4,647

- Reaction score

- 7,073

- Location

- At home, in the brewery in Maryland.

Wouldn’t O2 permeate the silicon? It might slow down splashing while at the same time permitting what a mash cap tries to prevent.

Do you all find a significant impact/improvement on the final product using these mash caps?

duelerx

Well-Known Member

- Joined

- Nov 5, 2015

- Messages

- 258

- Reaction score

- 93

You are correct, I highly recommend this stuff, all my brewhouse have it: https://www.usplastic.com/catalog/item.aspx?itemid=36307&catid=864Wouldn’t O2 permeate the silicon? It might slow down splashing while at the same time permitting what a mash cap tries to prevent.

It's a can 'o worms question. The general consensus is that oxygen is detrimental to wort, full stop. The debate is around "to what degree?" and "will you notice?"Do you all find a significant impact/improvement on the final product using these mash caps?

Similar threads

- Replies

- 45

- Views

- 4K

- Replies

- 0

- Views

- 987

- Replies

- 4

- Views

- 3K

- Replies

- 1

- Views

- 1K

- Replies

- 8

- Views

- 3K